Description

Urethane Pipeline Products typically refer to specialized components made from urethane (polyurethane) that are used in pipeline systems, especially in industries like oil and gas, mining, water treatment, and chemical processing. These products are valued for their durability, abrasion resistance, flexibility, and ability to withstand harsh operating environments.

🔧 Common Urethane Pipeline Products

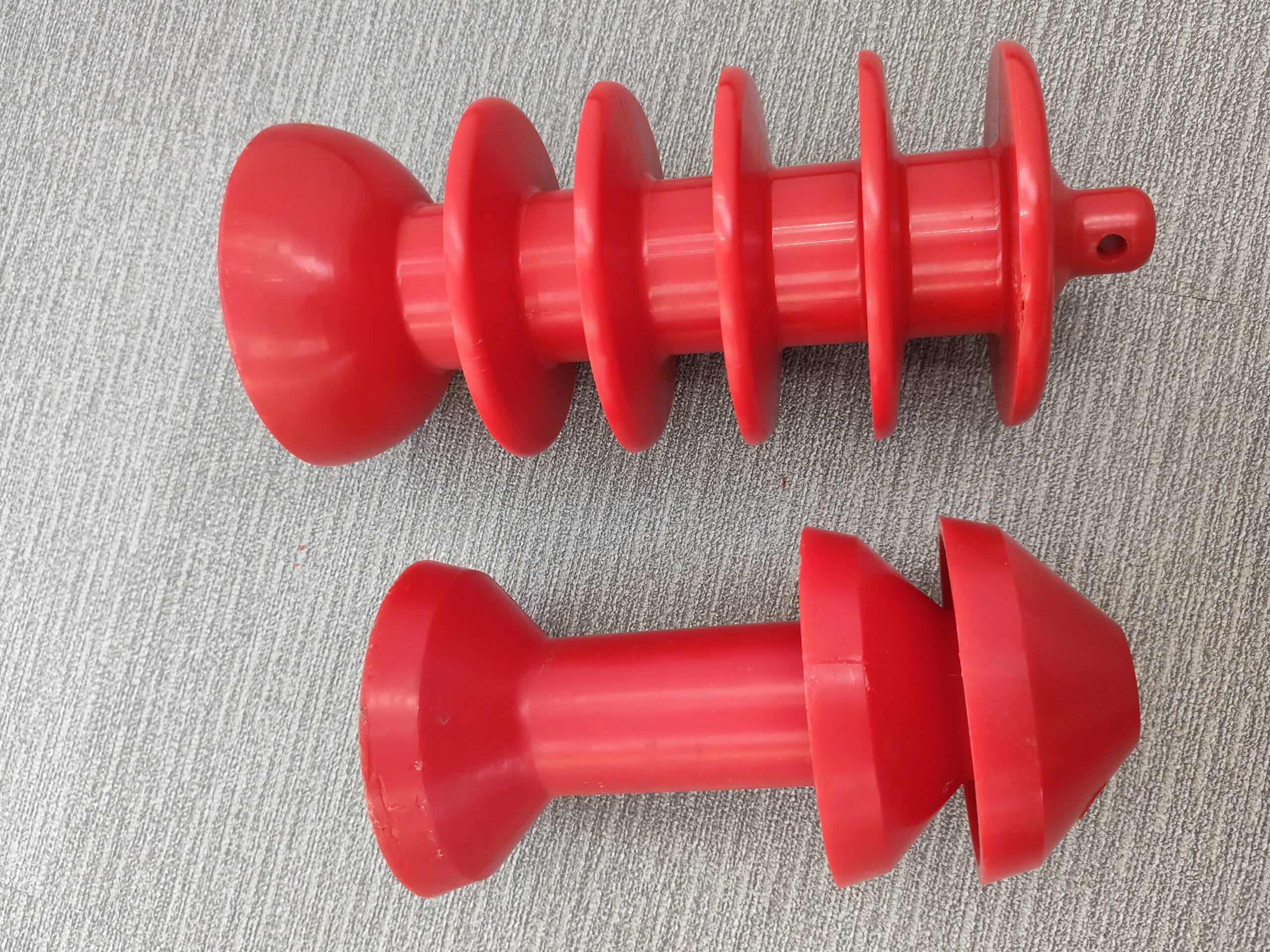

1. Pipeline Pigs

- Function: Clean and inspect pipelines.

- Types:

- Foam pigs

- Solid-cast urethane pigs

- Cup pigs

- Disc pigs

- Benefits: Long-lasting, flexible, and effective for cleaning without damaging the pipeline.

2. Sealing Discs & Cups

- Function: Used on pigs for sealing and propulsion through pipelines.

- Materials: Urethane gives them elasticity and resistance to wear.

3. Pipeline Scrapers

- Function: Remove debris, scale, or buildup inside pipelines.

- Design: Often integrated into pigs or standalone tools.

4. Pipeline Spacers & Centralizers

- Function: Maintain pipe alignment and spacing, especially in casing applications.

- Use Case: Common in directional drilling and pipeline installation.

5. Custom Urethane Molded Parts

- Function: Tailored to specific pipeline needs like valves, dampers, seals, etc.

- Customization: Often required for unique pipeline environments.

🏗️ Benefits of Urethane in Pipeline Applications

| Benefit | Description |

|---|---|

| Abrasion Resistance | Withstands wear from sand, chemicals, and debris. |

| Chemical Resistance | Handles exposure to oils, fuels, and harsh chemicals. |

| Flexibility & Toughness | Performs reliably under pressure and stress. |

| Low Friction | Reduces resistance inside the pipelines. |

| Temperature Tolerance | Suitable for both high and low temperatures. |

🏭 Industries That Use Urethane Pipeline Products

- Oil & Gas

- Mining

- Water & Wastewater

- Chemical Processing

- Food & Beverage (for sanitary pipelines)

What Is Pipeline Pigging?

Pipeline pigging is a maintenance and inspection process used in pipelines to clean, inspect, or separate different products during transportation. The term “pig” refers to the device that is inserted into and travels through the pipeline. Originally, pigs were made from straw and wire and made squealing sounds — hence the name “pig.”

Today, pigs are high-tech tools made from materials such as urethane, foam, metal, or a combination, and they are essential for safe and efficient pipeline operations.

Benefits of Pigging

Pigging offers several important benefits that enhance the performance and longevity of pipeline systems. First, it improves flow efficiency by removing internal buildup such as wax, scale, or debris that can restrict product movement. In addition, it reduces corrosion by eliminating water and other contaminants that contribute to internal pipeline degradation. Another key advantage is that it ensures product quality, as pigging prevents cross-contamination when different products are transported through the same pipeline. Furthermore, the process enhances pipeline safety by detecting potential issues like cracks, corrosion, or blockages before they lead to major failures. Lastly, by enabling regular maintenance and early issue detection, pigging significantly extends the operational life of pipelines, helping operators avoid costly repairs or replacements.