Description

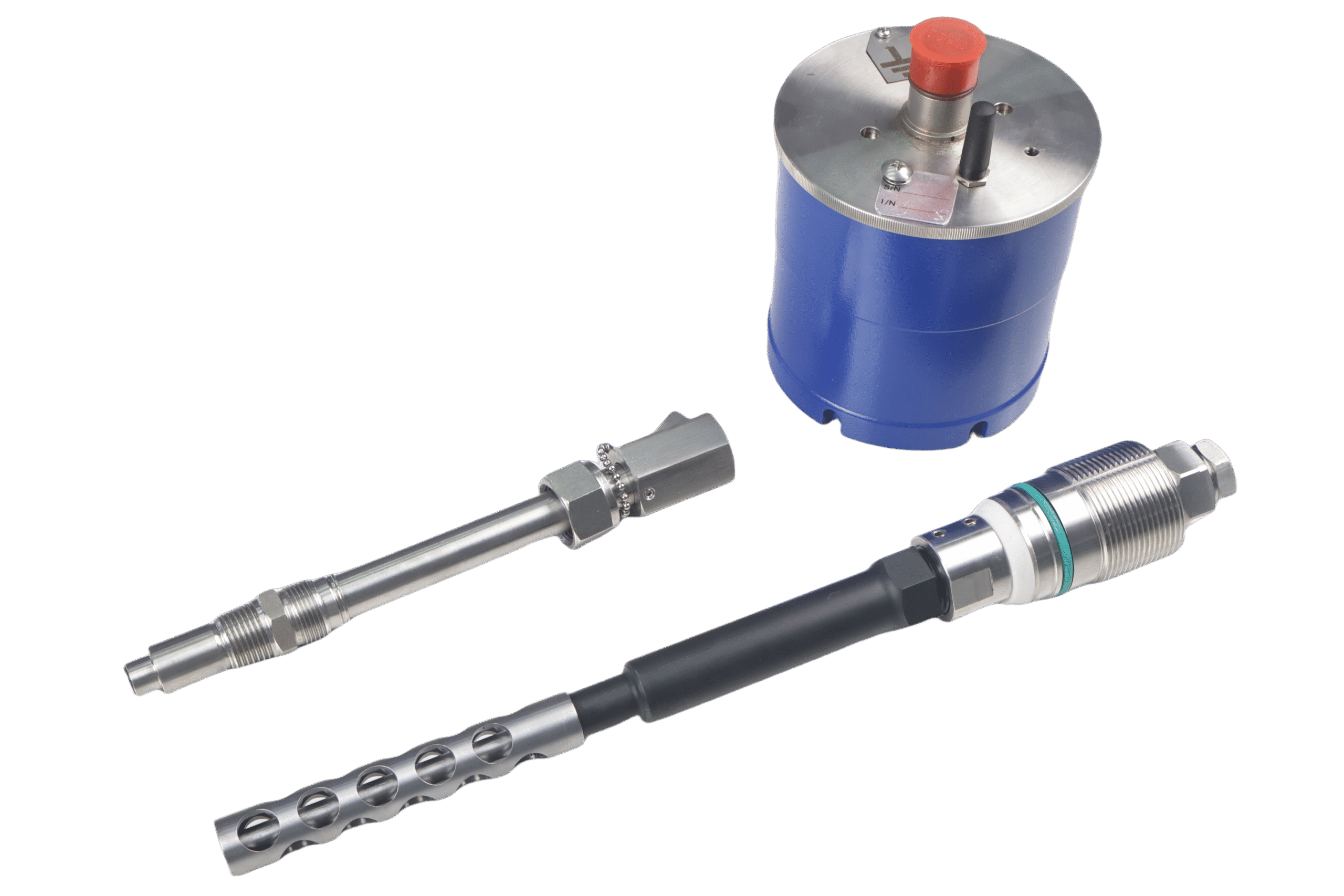

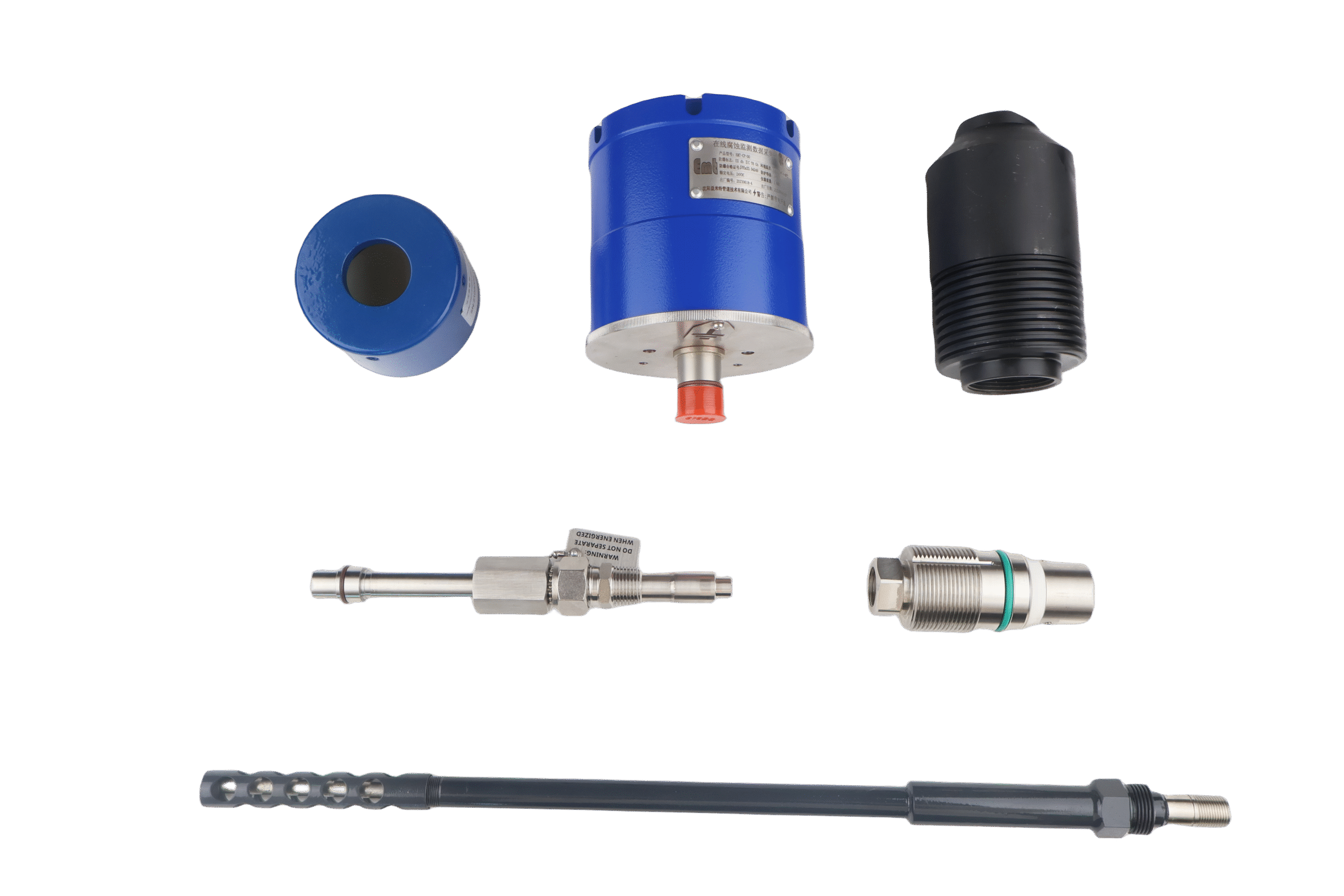

New and Improved EMT ER Corrosion Probe

We are pleased to introduce a new style of the EMT’s ER Corrosion Probe, featuring enhanced durability and improved connector design. This updated model includes:

- More robust construction for increased mechanical strength

- Shrouded pin connector to prevent accidental damage during handling

- Welded shields where necessary, ensuring better protection and performance

Important: This new design requires a different probe connecting adaptor. Please refer to the order details for compatibility information.

The Model 4500 ER probe continues to be our most rugged and reliable solution, offering exceptional mechanical durability and minimal sensitivity to temperature fluctuations. It is recommended for all new installations.

Parameters of Corrosion Probe

| LPR Corrosion Data Collector Technical Specification | |

| Technical Specifications | |

| Output signal | Wired form: RS-485 signal |

| Wireless form: LORA, 4G/5G wireless network signal | |

| Record form: Internal storage Bluetooth download | |

| Power supply voltage: | 7-36VDC |

| Instrument Power Consumption: | 5.4W(wired) |

| Linearity: | 0.0015% non-linearity |

| Resolution: | 17 bit |

| B Value: | 25.6 mV |

| Accuracy: | ±0.2% F.S(full scale) |

| Corrosion Rate Range: | When the electrode area is 1cm², the measurement range is 4X10^-4 to 10 mm/year |

| Operational and Storage Conditions | |

| Collector Operating Temperature: | -40~70℃ |

| Collector Storage Temperature: | -40~85℃ |

| Structural Parameters | |

| Protection Class: | IP66 |

| Housing Material: | Cast aluminum or PVC, aviation aluminum, stainless steel (customizable) |

| Process Interface: | 7/8-20UNEF (insertion probe) |

| Electrical Connection: | M20*1.5mm |

| Cable Type: | RVVP 2*1.5mm² (minimum application standard) |

| Installation: | Probe directly mounted on the pipeline, collector can be integrated or installed separately through a cable |

| Weight: | 500g |

| Direct Connection between Probe and Collector: | S22-16 adapter |

| Split Configuration Accessories: | Interface: MS-14-6S double female |

| Split Configuration Connection Cable: | Cable Length: 1-3 meters (customizable) |

| Certifications | |

| Hazardous Area Certification: | EX-d IIC T4 Gb |

Additional Design and Installation Notes

- Shields are recommended for applications involving high fluid velocities to ensure optimal probe performance and longevity.

- All welds are vacuum annealed during assembly to prevent preferential corrosion and enhance structural integrity.

- Probe adapters are required to establish a proper connection between the probe and the cable assembly.

Comprehensive Benefits

- Predicting the Lifespan of Infrastructure. Corrosion probes and coupons generate data that helps in understanding how quickly corrosion is occurring, which materials are most affected, and under what conditions the degradation accelerates. This information is crucial for predicting the lifespan of infrastructure and planning for its maintenance or replacement before failures occur.

- Ensuring Safety. Regular monitoring of corrosion levels allows industries to maintain structures safely and to standards, thereby minimizing the risk of catastrophic failures. This is particularly important in sectors where infrastructure failure can lead to significant environmental damage, loss of life, or financial repercussions.

- Optimizing Maintenance Costs. Corrosion monitoring enables companies to implement condition-based maintenance strategies. This approach focuses on performing maintenance only when necessary rather than following a fixed schedule. It helps in identifying specific areas that need attention, thus optimizing maintenance efforts and reducing the overall maintenance costs. Early detection of potential problems allows for smaller, less expensive repairs rather than more significant, costly interventions later.

- Enhancing Regulatory Compliance. Many industries are governed by strict regulatory standards which mandate regular monitoring and maintenance of equipment to prevent environmental and safety hazards. Using corrosion probes ensures compliance with these regulations by providing documented proof of proactive infrastructure management.

Applications and Benefits of Corrosion Probe

Corrosion probes and coupons are invaluable tools in the arsenal of industries aiming to maintain the integrity and functionality of their infrastructure. These devices not only provide direct insights into the rate of corrosion but also help in strategic planning and risk management across various sectors.

Diverse Industrial Applications

- Oil and Gas. In this sector, pipelines, storage tanks, and processing equipment are susceptible to corrosion due to the harsh chemicals and environmental conditions involved. Corrosion probes help monitor these components continuously, enabling timely maintenance actions that prevent leaks and ruptures which could lead to environmental disasters and financial losses.

- Chemical Processing. Chemical plants operate with substances that can rapidly degrade materials. By using corrosion probes, these facilities can monitor the effects of aggressive chemicals on their systems, thereby preventing equipment failure and ensuring continuous production without unscheduled downtimes.

- Water Treatment. Corrosion can compromise water quality and damage the infrastructure required to treat and transport water. Corrosion monitoring in this sector ensures that water remains safe for consumption and that the systems processing it are in optimal condition.

- Pharmaceuticals. In pharmaceutical manufacturing, the integrity of process vessels and piping is crucial. Corrosion could lead to contamination of medicines, affecting their purity and efficacy. Monitoring corrosion helps maintain the stringent quality standards required in pharmaceutical production.