Description

In industrial settings involving pipelines and pressurized vessels, monitoring fluid characteristics and ensuring system integrity are critical operational requirements. The Chemical Injector, also referred to as a Sampling and Injection Device, serves as a vital component for these purposes, enabling safe chemical injection and fluid sampling without process interruption.

1. Application of Chemical Injector

Chemical Injector is designed for two primary functions:

-

Chemical Injection: It allows operators to inject treatment chemicals (such as inhibitors, biocides, or scale preventatives) directly into a live pipeline using a high-pressure pump. This is crucial for maintaining fluid quality and protecting infrastructure from corrosion or deposits.

-

Fluid Sampling: The device can also be used to safely extract representative fluid samples from the pipeline under operating pressure and temperature for laboratory analysis. This helps in monitoring product quality, contamination levels, and the effectiveness of treatment programs.

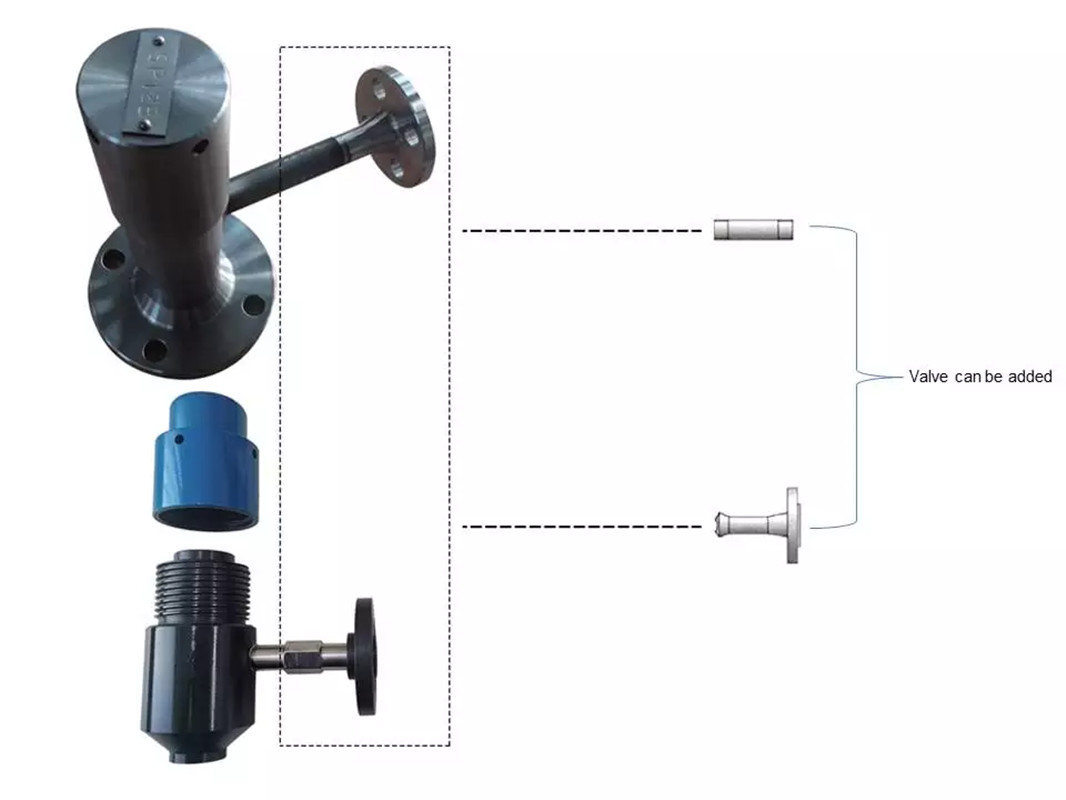

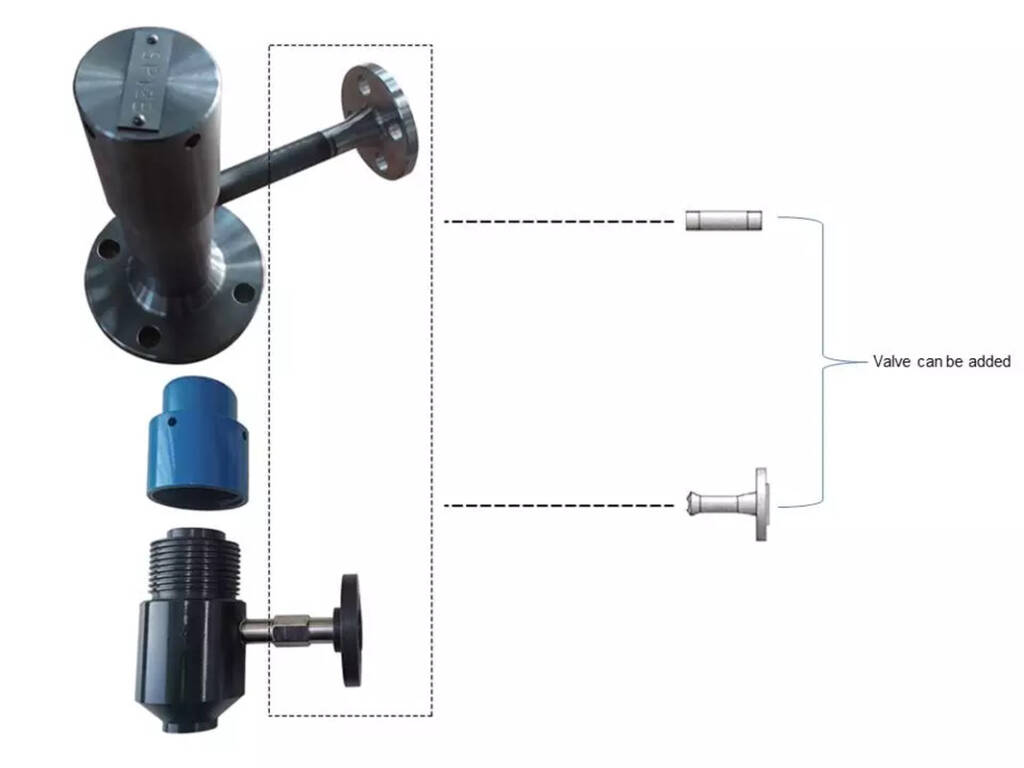

2. Key Components

Then the standard assembly of Chemical Injector includes several key parts that ensure its safe and reliable operation:

-

Base Flange: Provides the primary connection to the pipeline, typically meeting ANSI 2″ RF/RJ standards.

-

Plug and Seals: A central plug with primary and secondary seals maintains pressure integrity during operation and retrieval.

-

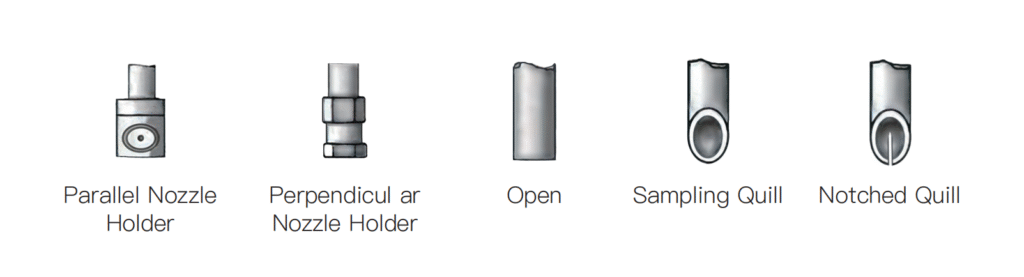

Injector Quill (Dropper): A probe that extends into the pipeline, directing injected chemicals into the flow or withdrawing samples.

-

Valve and Connecting Tube: Enable the connection to external pumps or sample containers and allow for safe isolation.

-

Protective Cover: Shields the internal components from external damage.

3. Parameters of Chemical Injector

Installation is a meticulous process to ensure the injector quill is correctly oriented. For injection, the quill’s opening must face the oncoming flow for optimal chemical dispersion. For sampling, orientation may vary. The device is designed to function under demanding conditions, typically supporting:

-

Operating Temperature: -20°C to 200°C

-

Operating Pressure: 0 to 26 MPa (approx. 3770 psi)

-

Connection Options: Various sizes (1/4″ to 1″) for the connecting tube and valve to suit different application needs.

4. Critical Safety Note

A paramount safety warning requires operators to keep any part of their body away from the interface port of the Chemical Injector during under-pressure operations, in order to prevent injury from potential medium leakage. So operators must wear proper personal protective equipment (PPE) and strictly follow all operational procedures.