Description

Pig Tracking Equipment Overview

Pig tracking systems are essential for pipeline maintenance operations, allowing operators to monitor the progress of pipeline inspection gauges (PIGs) as they travel through pipelines. Our systems typically consist of:

|

|

|

|

| Name | LCQZ-ZFS Intelligent Digital Transmitter | LCQZ-DFS High-power Transmitter | LCQZ-TFS Versatile Transmitter |

| Introduction | Using special integrated circuit and singlechip with more stable frequency and more available (above DN300). | Using high-power battery pack, the transmitting power is bigger and longer service hour. | Applying chargeable battery pack, rechargeable (above DN300). |

| Installation Size (Battery) | 1.2V * 10 chargeable battery pack 3.6V * 4 high energy battery |

3.6V * 4 high energy battery | 1.2V * 10 chargeable battery pack |

| Work Hour | 100~200 hours | 100~300 hours | 50 hours |

| Installation Size (Connection) | M64 * 1.5 | Flange connection | M64 * 1.5 |

| Type | ①L210, L260, L310 | ②L210, L260, L310 | ③L210, L260 |

| Remark | ①The number after “L” represents transmitter’s effective delivered power. | ②The number after “L” represents transmitter’s effective delivered power. | ③The number after “L” represents transmitter’s effective delivered power. |

Pig Transmitter (Tracking Transmitter)

- A device mounted on or integrated with the pipeline inspection gauge

- Emits a detectable signal (usually electromagnetic) as the pig travels through the pipeline

- Designed to withstand pipeline operating conditions (pressure, temperature, fluid types)

- Battery-powered with extended operational life

- Available in various frequencies to suit different pipeline conditions and depths

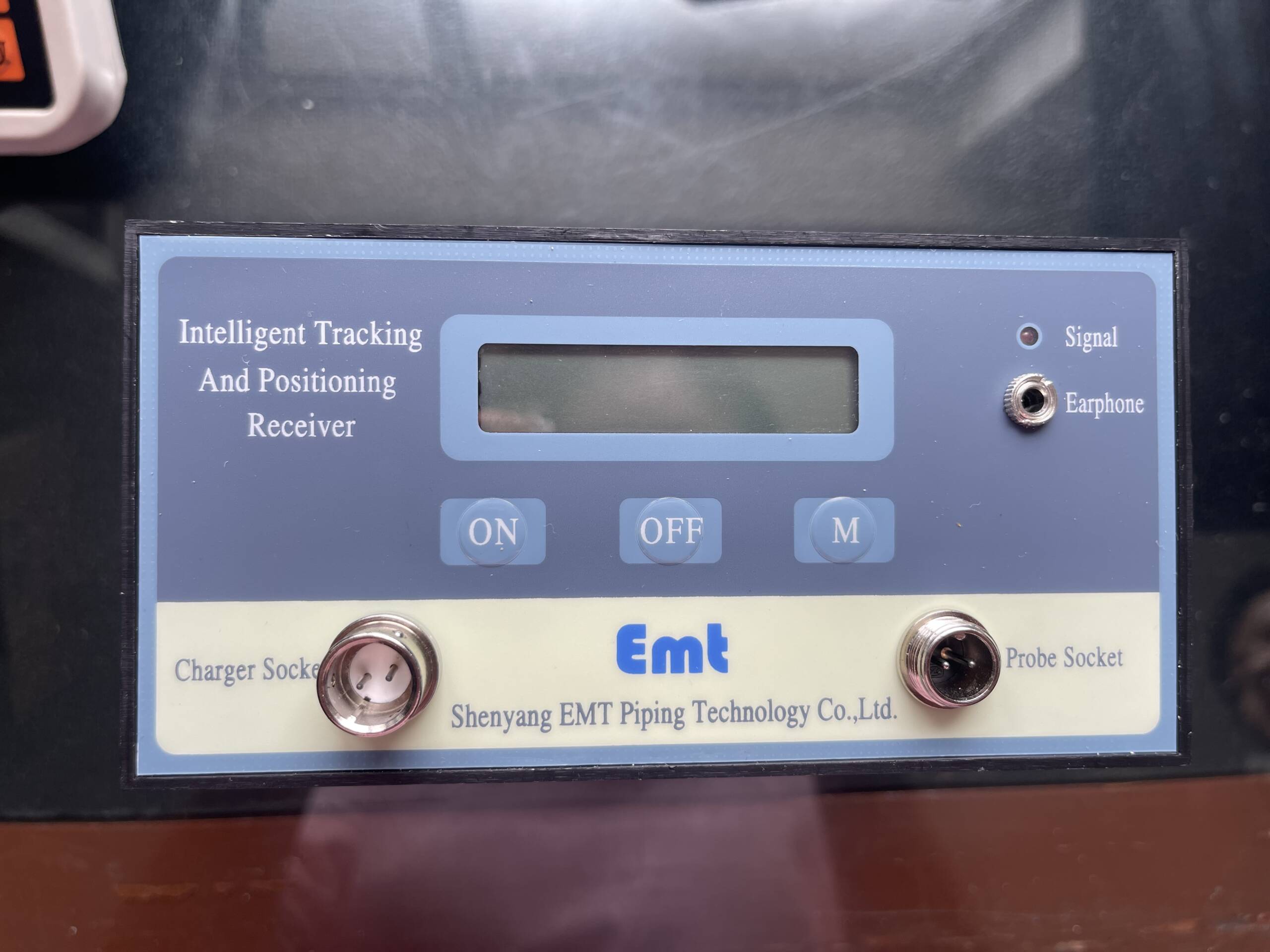

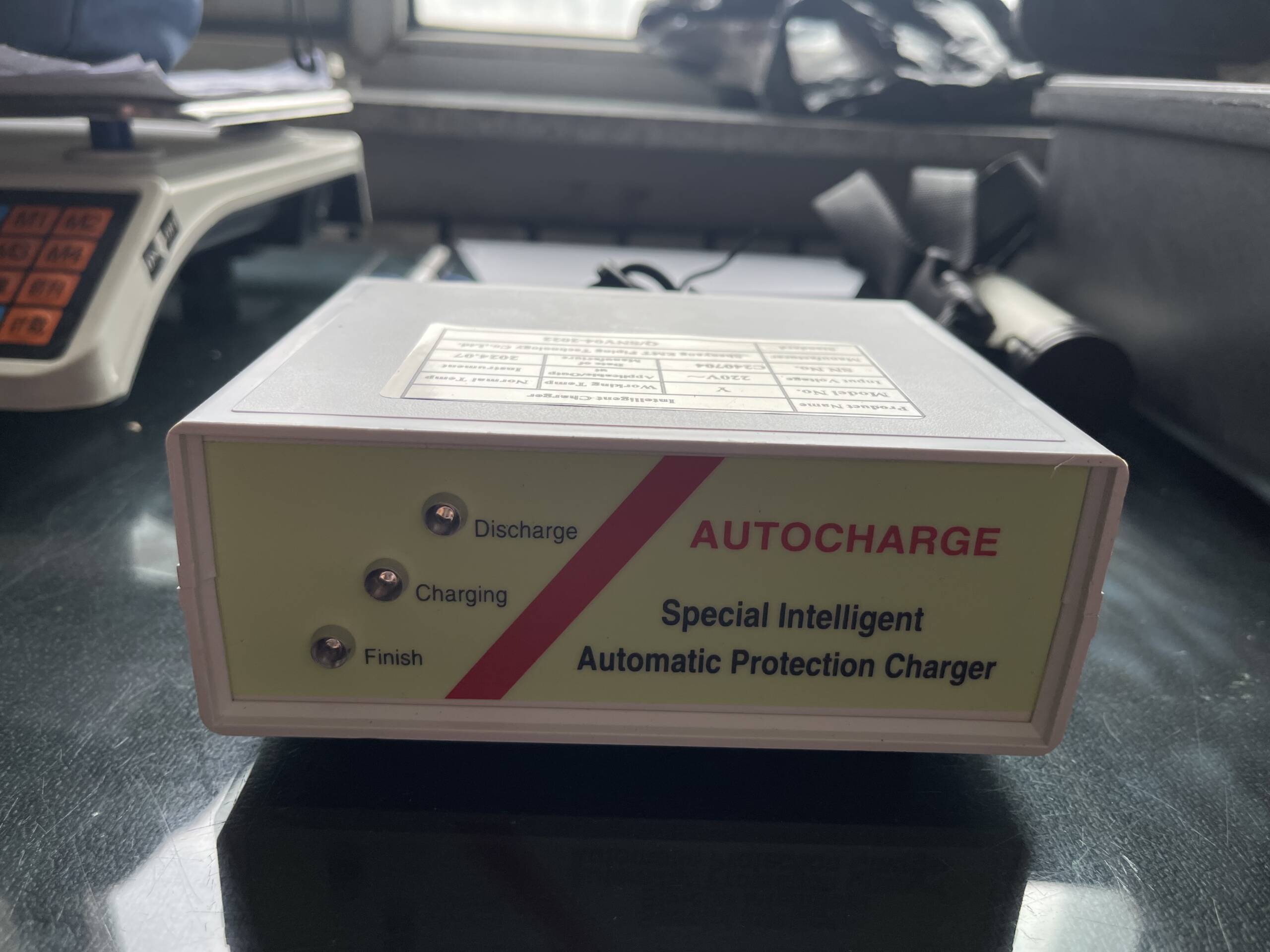

Receiver (Tracking Receiver)

- Handheld or vehicle-mounted detection device used above ground

- Picks up the signal emitted by the transmitter

- Provides location, depth, and signal strength information

- Typically features audible and visual indicators

- Some models include GPS integration for precise location mapping

Typical Applications

- Monitoring pig movement during cleaning operations

- Locating stuck pigs in pipelines

- Verifying pig passage through pipeline sections

- Pipeline integrity assessment operations

- Pre-commissioning pipeline verification