Description

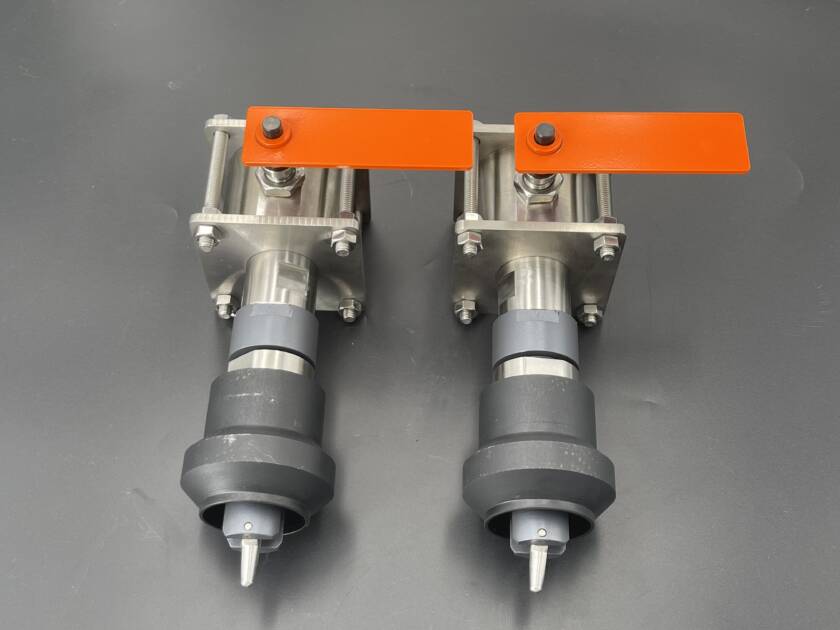

EMT Pipeline Pig Detector are essential tools for confirming the movement of pipeline pigs through various pipeline systems. Typically positioned at both the pig launching and receiving stations, as well as at key points along the pipeline, these signallers ensure accurate monitoring of pig passage.

1. Customized Pipeline Pig Detector

- Material Options: Available in a variety of durable materials, including Stainless Steel 304, Stainless Steel 316, DSS F51, Carbon Steel A105N, and Inconel 625, ensuring suitability for diverse operating conditions.

- Operating Temperature: Designed to function effectively within a temperature range of -20°C to +120°C.

- Features:

-

High Wear Resistance for Longevity

EMT Pipeline Pig Detectors are constructed using high-quality materials such as Stainless Steel 304, Stainless Steel 316, DSS F51, Carbon Steel A105N, and Inconel 625. These materials are selected for their exceptional wear resistance, allowing the signallers to withstand the harsh conditions often found in pipeline environments. This durability ensures a longer lifespan for the detectors, reducing the frequency of replacements and minimizing maintenance efforts. As a result, operators can rely on the signallers to perform consistently over time, enhancing the overall reliability of the pipeline monitoring system.

-

Excellent Cleaning Performance

The design of EMT Pig Detectors contributes significantly to their cleaning performance. By accurately detecting the passage of pipeline pigs, these signallers help operators monitor cleaning operations effectively. This real-time feedback allows for timely interventions if cleaning is insufficient or if debris is accumulating in specific areas of the pipeline. The efficient performance not only ensures that pipelines remain clear of obstructions but also enhances the flow of fluids, improving operational efficiency. As a result, the overall productivity of the pipeline system is elevated, leading to better resource management and reduced operational costs.

-

Cost-Effective Design

EMT Pig Detectors are engineered with a cost-effective design that does not compromise on quality or performance. Their lightweight and flexible nature facilitates easy installation, which reduces labor costs and downtime during setup. Additionally, the durability and longevity of the materials used minimize the need for frequent replacements, leading to significant savings over time. For budget-conscious operations, this combination of affordability and reliability makes the EMT Pig Detectors an attractive investment, providing excellent value without sacrificing operational effectiveness. By choosing these signallers, companies can enhance their pipeline management while adhering to budget constraints.

-

2. Advantages

2. Advantages

-

Lightweight and Flexible

The EMT Pipeline Pig Detector is designed with a lightweight construction, making them easy to handle and install. Their flexible design allows for quick adaptation to various pipeline configurations, whether the pipeline is straight, curved, or has multiple junctions. This adaptability ensures that the signallers can be effectively utilized in diverse environments, reducing installation time and labor costs. Additionally, their compact size allows for unobtrusive placement within existing systems, minimizing disruption during installation or maintenance activities.

-

Efficient Cleaning

These signallers play a crucial role in enhancing cleaning operations within pipelines. By providing real-time feedback on pig movement, they help operators identify areas that may require additional attention or cleaning. This proactive approach not only improves the overall efficiency of cleaning processes but also contributes to the maintenance of pipeline integrity. Regular monitoring ensures that contaminants. Such as sludge and debris, are effectively removed, reducing the risk of blockages and extending the lifespan of the pipeline infrastructure.

-

Accurate Location Tracking

One of the standout features of EMT Pig Signallers is their ability to provide precise confirmation of pig passage. This accurate location tracking is essential for operational reliability, as it allows operators to monitor the movement of pigs throughout the pipeline system. By knowing exactly when and where a pig has passed, operators can better manage maintenance schedules and respond quickly to any issues that may arise. This capability not only enhances safety by ensuring that pigs are properly accounted for but also improves overall pipeline management, allowing for more efficient operation and reduced downtime.

3. Types of EMT Pipeline Pig Detectors

3. Types of EMT Pipeline Pig Detectors

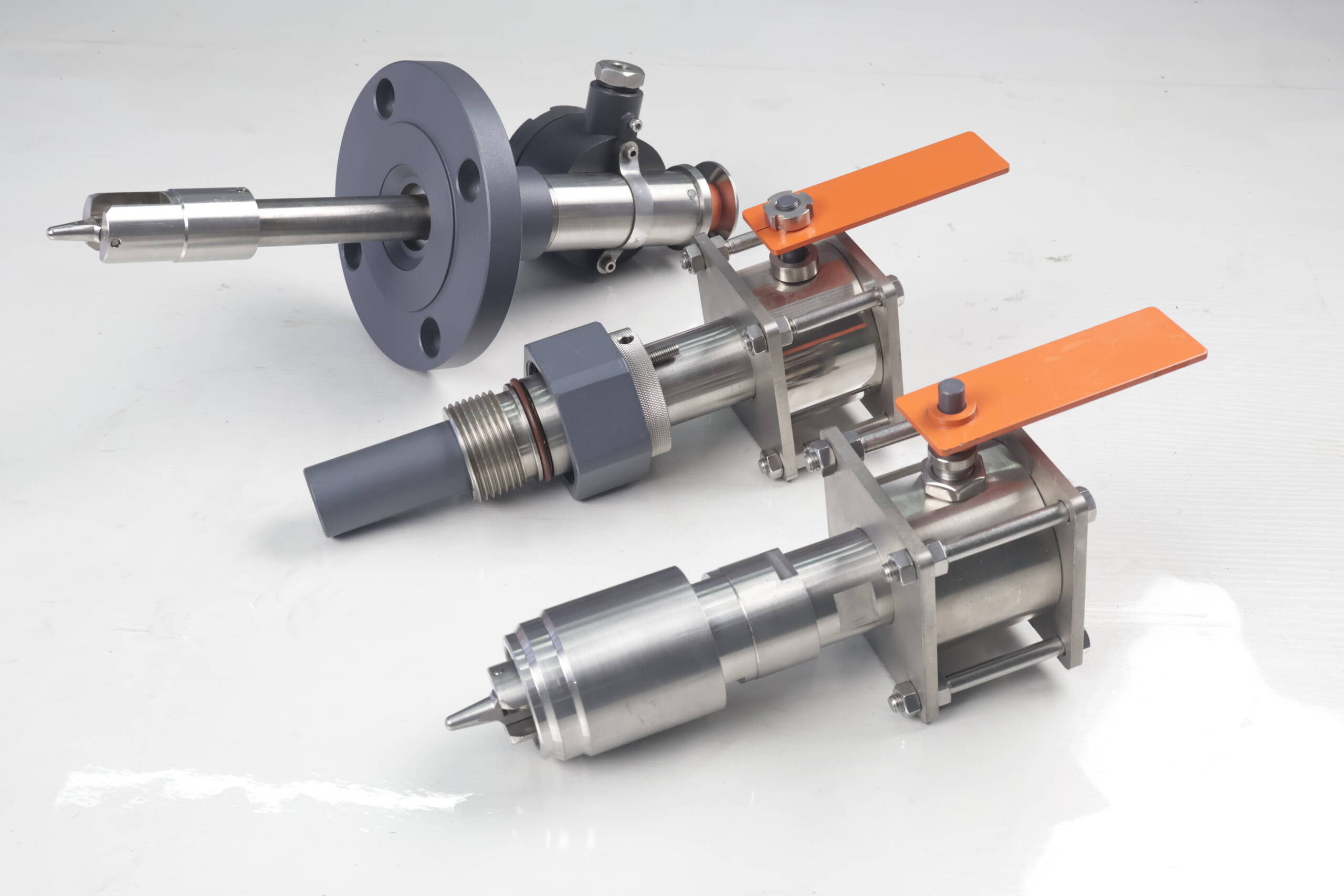

EMT pipeline pig detector is designed with versatility in mind, offering a range of trigger types, indicator options, and mounting configurations to meet various operational needs.

-

Trigger Types

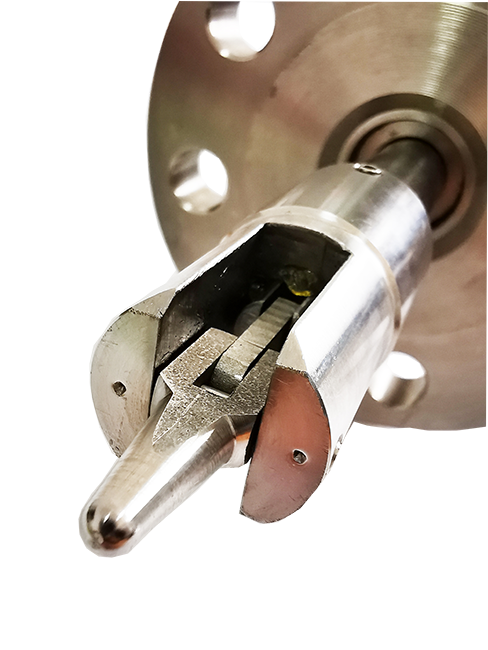

- Bi-directional. This trigger type detects the passage of pipeline pigs moving in both directions. It also makes it ideal for pipelines that require frequent pigging in either flow direction. This feature enhances monitoring flexibility and ensures comprehensive tracking of pig movement.

- Bi-directional Feather. Similar to the standard bi-directional trigger, the bi-directional feather trigger provides an added layer of sensitivity. This design minimizes the risk of false triggers while still accurately detecting pigs moving in either direction. It is particularly useful in pipelines with variable flow rates or where precise detection is critical.

- Uni-directional. The uni-directional trigger is designed for pipelines where pigs only travel in one direction. This simplicity can lead to cost savings and easier installation, making it an efficient choice for straightforward pipeline systems.

-

Indicator Types

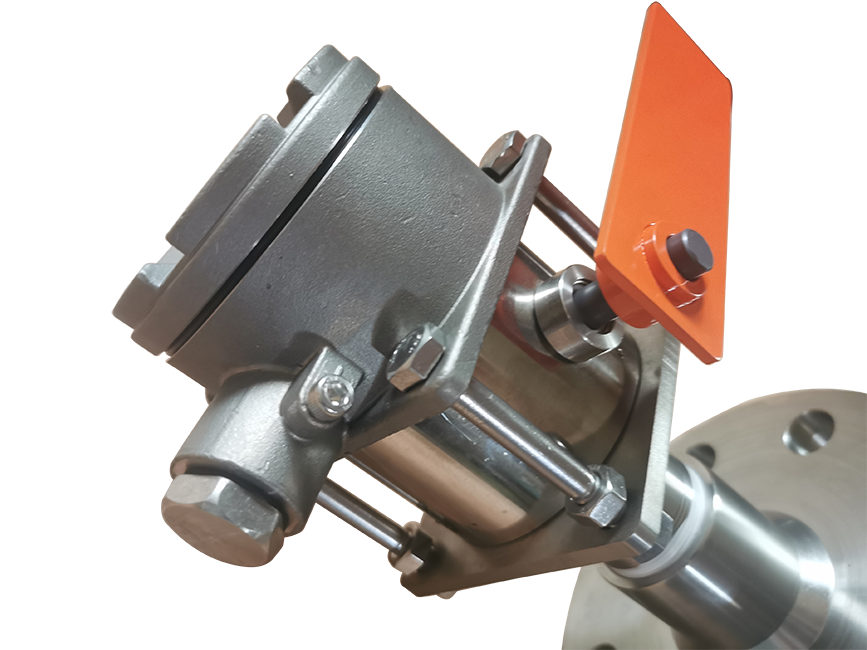

- B – Manual Reset Flag. This indicator features a manual reset mechanism, allowing operators to confirm pig passage visually. It is straightforward and effective for basic monitoring needs.

- C – Manual Reset Flag Combined with Electrical Switch Output. This option combines a manual reset flag with an electrical switch output, providing both visual confirmation and automated signals for integration with control systems. This dual functionality enhances monitoring efficiency and facilitates automation.

- D – Digital Display Combined with Electrical Switch Output. The digital display option offers real-time information on pig passage and system status. Coupled with electrical switch outputs, it allows for seamless integration into existing monitoring systems, providing operators with immediate access to critical data.

-

Mounting Types

- 2″ Flange Connection. This mounting type provides a secure and robust installation method, suitable for various pipeline configurations. The flange connection ensures easy access for maintenance and inspection.

- 2″ Welded Nipple. The welded nipple mounting offers a strong, permanent connection to the pipeline, minimizing the risk of leaks. This type is ideal for high-pressure applications where durability is essential.

- 2″ Welded Base – NPT Nipple Connection. This mounting configuration combines the benefits of a welded base with a National Pipe Taper (NPT) connection. Therefore it ensures a tight seal and compatibility with standard pipeline fittings. It is particularly useful in situations where adaptability and ease of installation are required.