Description

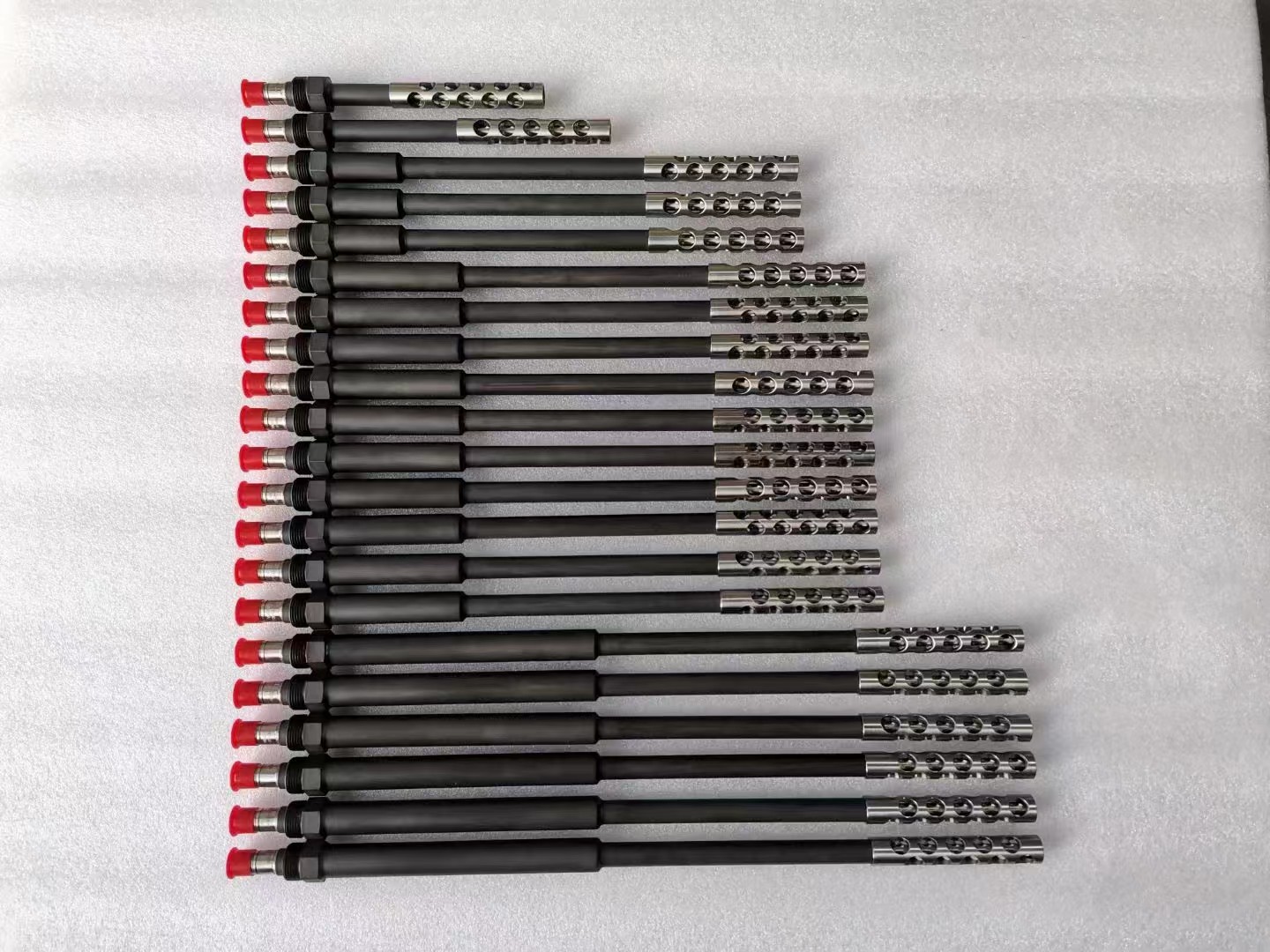

The EMT-EP100 model is a fixed-length, retrievable electrical resistance (ER) probe specifically designed for corrosion monitoring in high-pressure access systems. Its robust construction and fully welded structure make it suitable for a wide range of harsh environments, ensuring reliable performance under challenging conditions.

1. Description

The EMT-EP100 probe assembly consists of an extension rod fitted with a sensing element and a threaded connecting seat. Each component of the probe is meticulously welded and sealed, with the interface end sealed using high-temperature glass sintering. This design not only enhances durability but also prevents media leakage, a critical consideration in high-pressure applications.

The probe sensor can be equipped with a protective cap to further safeguard the sensing element during operation. Once the probe is installed into the hollow plug using a probe nut and sealing ring, it can be retrieved or installed in-line without requiring a shutdown of the process. This capability is facilitated by a retrieval tool and service valve, allowing for efficient maintenance and monitoring without disrupting operations.

Note: The probe adapter, necessary for connecting the collector, must be ordered separately.

Specifications

- Probe Body Materials: Available in 316 Stainless Steel (SS), 316L Stainless Steel (SS), Duplex Stainless Steel (DSS), and Inconel, ensuring compatibility with various media and environments.

- Temperature Rating: Supports a wide temperature range from -200°C to 260°C, with an optional higher range of 260°C to 450°C to accommodate different operational needs.

- Pressure Rating: Designed to function effectively in conditions less than 45 MPa, making it suitable for high-pressure systems.

- Mounting: Specifically engineered for access systems featuring a hollow plug.

2. Key Features of the ER Probe for Corrosion Monitoring

Durable Construction

The EMT-EP100 ER Probe is built with a fully welded structure that can withstand harsh environmental conditions. This robust design not only enhances the probe’s longevity but also effectively prevents media leakage, ensuring reliable operation even in demanding applications.

Sensing Element

The probe features an extension rod equipped with a high-temperature glass-sintered seal at the interface. This design enhances the integrity of the sensing element, allowing for accurate and consistent readings of corrosion levels while protecting against environmental contaminants.

Retrievability

One of the standout features of the EMT-EP100 is its retrievability. The probe can be easily installed or retrieved without requiring a shutdown of the process. This is achieved through the use of a specialized retrieval tool and service valve, enabling maintenance and monitoring without disrupting operations, thus saving time and resources.

Material Options

To ensure compatibility with a variety of media and environments, the probe is available in multiple material options, including:

- 316 Stainless Steel (SS)

- 316L Stainless Steel (SS)

- Duplex Stainless Steel (DSS)

- Inconel

These materials provide excellent resistance to corrosion and high temperatures, making the probe suitable for diverse applications.

Temperature Range

The EMT-EP100 operates effectively within a wide temperature range of -200°C to 260°C. For applications requiring higher temperatures, an optional range of 260°C to 450°C is also available, accommodating various operational needs in different environments.

Pressure Rating

Designed to excel in high-pressure environments, the probe is rated for pressures up to 45 MPa. This capability makes it ideal for use in systems where pressure management is critical, ensuring safety and reliability.

Mounting Compatibility

The probe is specifically designed for use in access systems featuring a hollow plug. This mounting compatibility facilitates straightforward integration into existing systems, allowing for seamless installation and use.

3. Application of the ER Probe for Corrosion Monitoring

The EMT-EP100 ER Probe is a crucial tool for monitoring corrosion in high-pressure access systems, serving various industries where pipeline integrity and safety are paramount. Here are the key applications of the probe:

1) Pipeline Integrity Monitoring

The primary function of the EMT-EP100 is to provide real-time data on corrosion levels within pipelines. Regular monitoring allows operators to detect early signs of corrosion, enabling timely interventions that can prevent catastrophic failures. By ensuring the integrity of pipelines, the probe helps maintain operational continuity and safety.

2) Oil and Gas Industry

In the oil and gas sector, pipelines often operate under extreme conditions, including high pressures and exposure to corrosive substances. The EMT-EP100 is specifically designed to withstand these harsh environments, making it ideal for:

- Crude Oil Transport: Monitoring corrosion in pipelines transporting crude oil, which can contain aggressive compounds that accelerate corrosion.

- Natural Gas Lines: Ensuring the integrity of natural gas pipelines, where even minor leaks can pose significant risks.

- Offshore Platforms: Used in offshore applications, where environmental factors like saltwater exacerbate corrosion issues.

3) Chemical Processing

The chemical processing industry frequently deals with aggressive chemicals that can corrode pipelines and equipment. The EMT-EP100’s corrosion-resistant materials, such as Inconel and Duplex Stainless Steel, make it suitable for:

- Monitoring Reactors and Storage Tanks: Providing critical data on the condition of equipment that handles corrosive substances.

- Ensuring Safety: By detecting corrosion early, the probe helps prevent leaks and hazardous incidents, enhancing workplace safety.

4) Energy Sector

In power generation facilities, including coal, nuclear, and renewable energy plants, the EMT-EP100 plays a vital role in:

- Monitoring Cooling Systems: Corrosion in cooling water systems can lead to efficiency losses and system failures. The probe helps maintain optimal performance by providing timely corrosion insights.

- Maintaining Boiler Integrity: Ensuring the integrity of boilers and associated piping systems, where corrosion can lead to significant operational risks.

5) Maintenance and Inspection

The retrievable design of the EMT-EP100 allows for easy installation and removal, facilitating routine maintenance and inspection processes. So this feature enables:

- Reduced Downtime: Operators can inspect and replace the probe without shutting down processes, minimizing operational interruptions.

- Improved Asset Management: Regular monitoring and maintenance informed by the probe’s data result in better asset management, extending the lifespan of equipment and infrastructure.

6) Infrastructure and Utilities

The probe is also applicable in municipal water systems and infrastructure projects, where monitoring the corrosion of pipes and fittings is crucial for maintaining water quality and system reliability. Its use in these applications helps:

- Ensure Safe Drinking Water: By monitoring corrosion in water supply pipelines, the probe helps prevent contamination and ensures compliance with health standards.

- Support Infrastructure Longevity: Regular corrosion assessments contribute to the long-term viability of critical infrastructure, then reducing the need for costly repairs and replacements.