Description

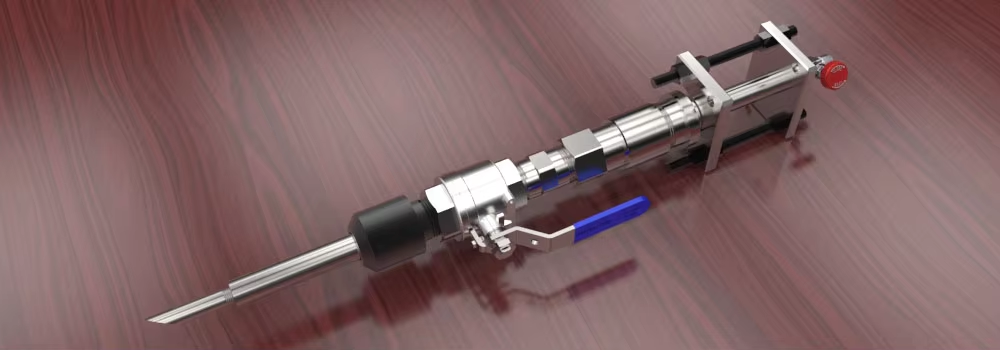

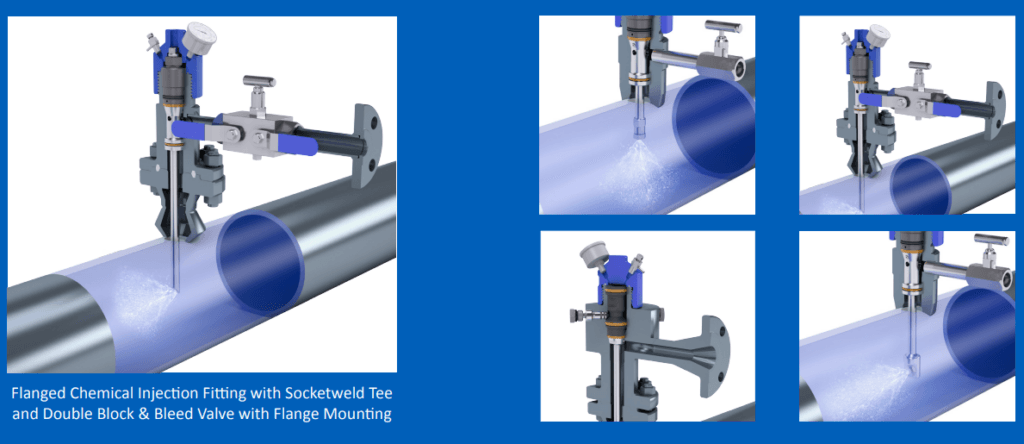

EMT Pigging meticulously engineers its Chemical Injection Quills for Oil and Gas to enhance both accuracy and safety in chemical injection operations, crucial for maintaining industrial pipelines. Initially, the design of these quills allows for the precise delivery of chemicals. This precision ensures that the system injects chemicals directly into the center of the pipeline. Following this direct delivery, the quills ensure optimal dispersion and absorption of the chemicals. This methodical process guarantees that the chemicals effectively interact with the process fluid, thereby maintaining the integrity and efficiency of the pipeline system.

Chemical Injection in Oil and Gas |

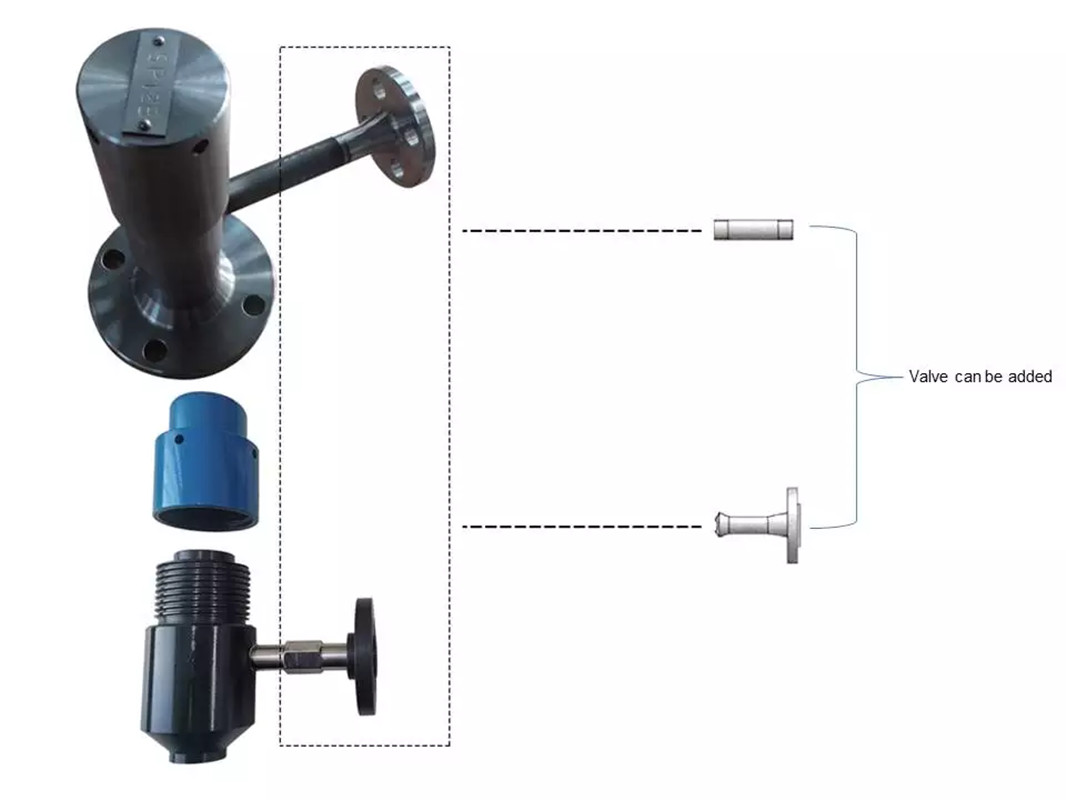

||||||||||||||||||||||||||||

| SI | Chemical Injection in Oil and Gas Access Fitting | |||||||||||||||||||||||||||

| -Code | Plug | |||||||||||||||||||||||||||

| Pxxx | Type | Material | Sealing Material | |||||||||||||||||||||||||

| 0 | No Request | 0 | CS | 0 | No Request | |||||||||||||||||||||||

| 1 | Hollow Plug Body | 1 | 316SS | 3 | DSS | 1 | Viton O-Ring / PTFE Primary Packing | |||||||||||||||||||||

| 2 | Solid Plug Body | 2 | 316LSS | 4 | INCONEL | 2 | HNBR | |||||||||||||||||||||

| Code | Injection Nut | |||||||||||||||||||||||||||

| Nxx | Connection Size | Material | ||||||||||||||||||||||||||

| 0 | i.e. No Request | 0 | i.e. CS | |||||||||||||||||||||||||

| 1 | i.e. 1/4″ | 1 | i.e. 316SS | 3 | i.e. DSS | |||||||||||||||||||||||

| 2 | i.e. 1/2″ | 2 | i.e. 316LSS | 4 | i.e. INCONEL | |||||||||||||||||||||||

| – Code | Injection Tube | |||||||||||||||||||||||||||

| Sxxx-Lx″ | Connection Size | Material | Nozzle | Line size(x″) | ||||||||||||||||||||||||

| 0 | No Request | 0 | CS | 0 | i.e. No Request | The most effective position for injection is generally at the center of the pipe | ||||||||||||||||||||||

| 1 | i.e. 1/4″ | 1 | i.e. 316SS | 1 | i.e. Open | |||||||||||||||||||||||

| 2 | i.e. 1/2″ | 2 | i.e. 316LSS | 2 | i.e. Quill | |||||||||||||||||||||||

| 3 | i.e. DSS | 3 | i.e. Cap & Core | |||||||||||||||||||||||||

| 4 | i.e. INCONEL | |||||||||||||||||||||||||||

| – Code | Nipple and Valve (or End Flange) of the Tee | |||||||||||||||||||||||||||

| Txx | Connection Size | Material | ||||||||||||||||||||||||||

| 0 | i.e. No Request | 0 | i.e. CS | |||||||||||||||||||||||||

| 1 | i.e. 1/4″Nipple | a | i.e. 1/4″Nipple and Valve | 1 | i.e. 316SS | |||||||||||||||||||||||

| 2 | i.e. 1/2″Nipple | b | i.e. 1/2″Nipple and Valve | 2 | i.e. 316LSS | |||||||||||||||||||||||

| 3 | i.e. 3/4″Nipple | c | i.e. 3/4″Nipple and Valve | 3 | i.e. D SS | |||||||||||||||||||||||

| 4 | i.e. 1″Nipple | d | i.e. 1″Nipple and Valve | 4 | i.e. INCONEL | |||||||||||||||||||||||

| 5 | i.e. 1/4″Flange | e | i.e. 1/4″Nipple end Flange | |||||||||||||||||||||||||

| 6 | i.e. 1/2″Flange | f | i.e. 1/2″Nipple end Flange | |||||||||||||||||||||||||

| 7 | i.e. 3/4″Flange | g | i.e. 3/4″Nipple end Flange | |||||||||||||||||||||||||

| 8 | i.e. 1″Flange | h | i.e. 1″Nipple end Flange | |||||||||||||||||||||||||

| P221: e.g. Solid Plug Body in 316LSS Viton O-Ring and PTFE Primary packing

N12: e.g., injection Nut Connection Size is 1/4″and Material is316LSS, S122:e.g. injection The tube connection size is 1/4 ″ and the material is 316LSS. The type of nozzle is quills L4″:For 4″pipe. T22:Nippleof Tee Connection Size is 1/2″,Nipple material is316LSS |

||||||||||||||||||||||||||||

Key Advantages of Chemical Injection

-

Precise Chemical Dosing

Enables accurate injection directly into the center of the flow, ensuring optimal mixing and treatment effectiveness while minimizing chemical waste. -

Pipeline Integrity Protection

Reduces direct chemical contact with pipe walls, preventing localized corrosion and erosion to extend pipeline service life. -

Enhanced Operational Safety

Allows for maintenance, inspection, and replacement under pressure without process shutdown, minimizing operational risks and exposure hazards. -

Improved Flow Assurance

Helps prevent blockages, scaling, corrosion, and hydrate formation, ensuring continuous and efficient pipeline transportation. -

Reduced Maintenance & Downtime

Retractable design simplifies servicing and part replacement, significantly cutting downtime and labor costs. -

Compatibility & Flexibility

Suitable for a wide range of chemicals including inhibitors, biocides, antifoams, and dispersants, meeting diverse operational needs in oil and gas applications.

Applications of Retractable Injection Quills:

Retractable injection quills are critical for precise chemical injection in oil and gas pipelines, enhancing operational safety, efficiency, and integrity.

-

Corrosion Inhibition

Inject corrosion inhibitors directly into pipelines to protect internal surfaces from corrosive fluids, significantly extending service life. -

Scale Prevention

Introduce scale inhibitors to prevent mineral deposition and scaling, maintaining flow efficiency and avoiding clogging or damage. -

Foam Control

Deliver anti-foaming agents to suppress foam formation in crude processing or separation stages, ensuring stable operation. -

Sludge & Deposit Management

Inject dispersants to break down and control sludge, solids, or asphaltene deposits, reducing maintenance frequency and enhancing flow assurance. -

Hydrate Inhibition

Enable accurate injection of thermodynamic or kinetic hydrate inhibitors in natural gas pipelines to prevent blockages and ensure continuous flow.