Description

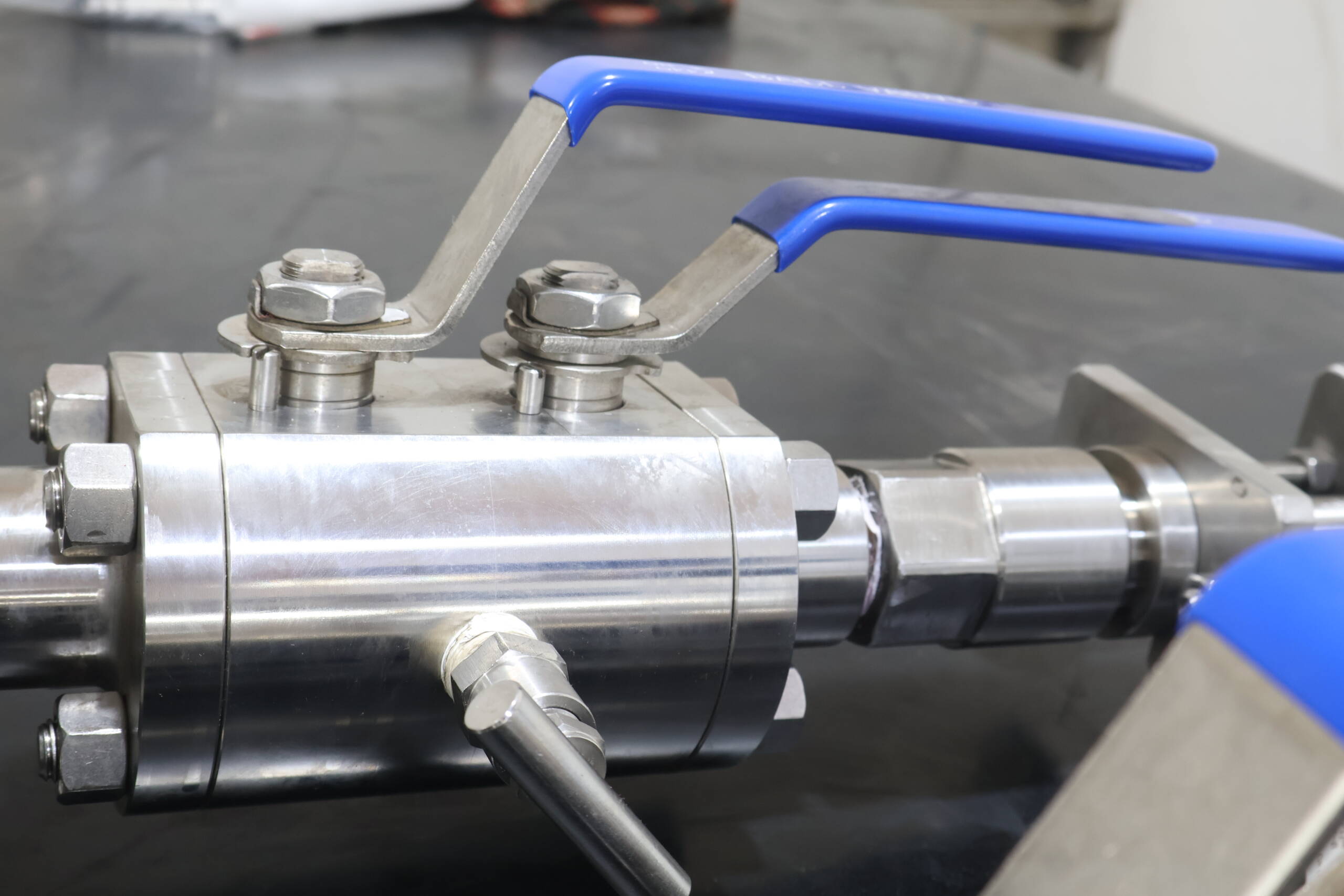

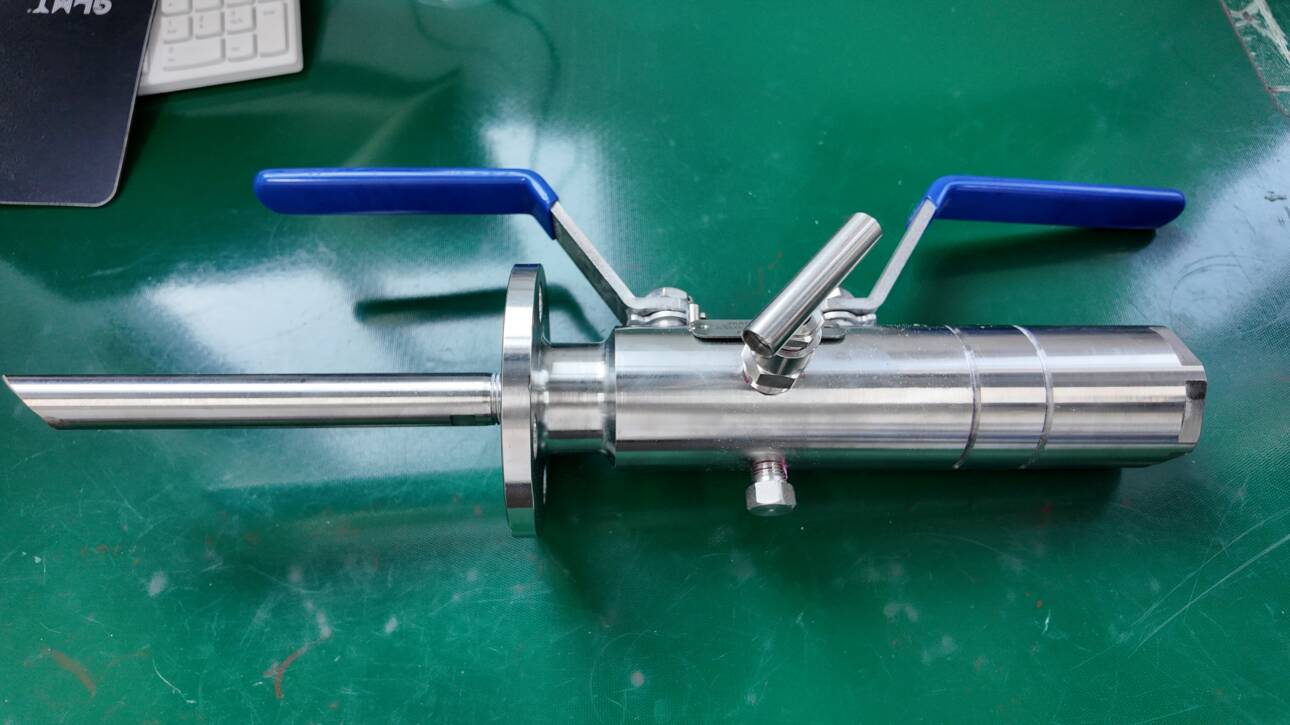

An EMT Removable Pig Signaler with DBB Valve is a specialized assembly used in pipeline operations, combining a pig signaler and a Double Block and Bleed (DBB) valve. Here’s a breakdown of what each component does and how they work together in this configuration:

What is a Pig Signaler?

A pig signaler detects the passage of a “pig” (a tool sent through a pipeline) at specific points along the pipeline during maintenance tasks. Operators use pigs for cleaning, inspecting, or separating different products within the line. The signaler informs operators that the pig has passed a particular point. This ensures that it is moving as expected through the pipeline. This monitoring helps prevent potential blockages or inefficiencies, safeguarding the pipeline’s operational integrity.

What is a DBB Valve?

A Double Block and Bleed (DBB) valve is an essential component for ensuring safety and operational efficiency in pipeline systems. It consists of two in-line isolation valves and a bleed valve, used in sequence to isolate the system and safely vent any excess medium trapped between the two valves. This configuration ensures a high level of safety and reduces the system’s footprint compared to having multiple valves.

Parameters of Removable Pig Signaler

| Specification | |

| Type | Intrusive |

| Connection Type | Flange connection |

| Indicator Feature | Manual reset flag; Date and time display combined with electrical signals (optional) |

| Installing Type | 2″ Flange, ASME B16.5 (CLASS 150-2500) |

| Plug Body Length | 200 mm or as per actual needs |

| Insert Depth Adjustment | 20 mm |

| Operating Temperature | -20 to 120°C or as per customer requirements |

| NACE | MR 0175 |

| Ingress Protection | IP66 |

| Explosion-Proof Class | Exd II BT4 |

| Remove Under Pressure | No |

| Trigger Type | Bi-directional (Uni-directional trigger also available) |

| Internal Part Material | PTFE Coated A105N (Options: 304SS, 316LSS, DSS, INCONEL, or as per MR) |

| Junction Box Material | Aluminium alloy or 316SS |

| Switch Type | DPDT or 2*SPDT |

| Switch Rating | DC24V 3A or DC24V 5A |

Combining the Two

Integration:

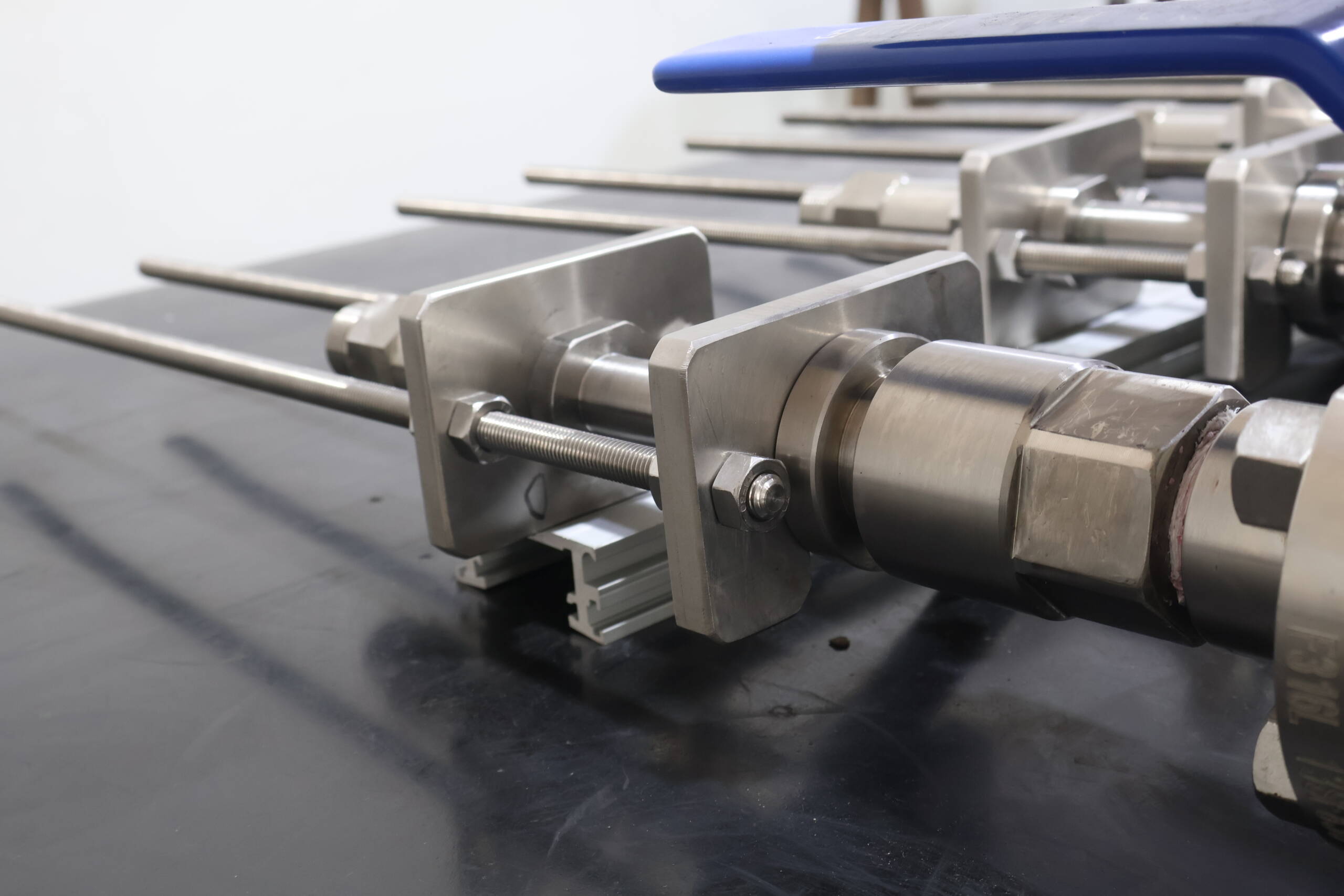

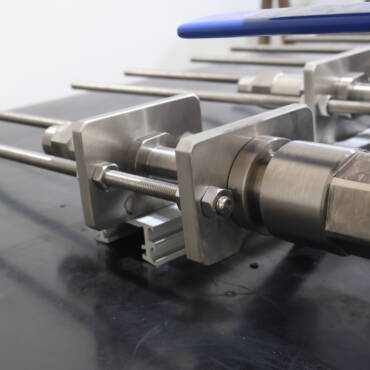

The integration of a removable pig signaler with a DBB valve allows for easy installation and removal. It can be done without shutting down the entire pipeline. This is possible because the DBB valve isolates the specific section where the signaler is installed. This isolation allows for safe maintenance or replacement activities.

Operation: In operation, the pig passes through the pipeline and triggers the pig signaler. The signal can be mechanical (e.g., a flag pop-up) or electronic (sending a signal to a control room). The DBB valve’s role during this operation is mainly to provide isolation and safety during the installation or removal of the signaler.

Safety and Efficiency:

The use of a DBB valve enhances safety by providing a fail-safe isolation mechanism when accessing the pig signaler. It allows for any necessary maintenance without the need for complete pipeline shutdown, thus minimizing downtime and maintaining continuous flow in other sections of the pipeline.

Maintenance: Maintenance of the pig signaler becomes easier and safer. The DBB valve configuration allows for the signaler to be serviced or replaced under live conditions, provided that the proper isolation and bleeding procedures are followed.

Selection Model Form

| Configuration parameter | |||

| ●standard configuration | ○Optional configuration | — No | |

| Trigger type(b-bidirectional /f-bidirectional feather /u-u-unidirectional) | ○/○/● | ||

| Flag trigger interagency interaction (no / Yes _ the flexibility of the trigger mechanism can be checked online) | —/● | —/● | —/— |

| Wetted part material(316L SS/DSS/INCONEL) | ●/○/○ | ||

| Flange/welding base material(PTFE Coated A105N/304SS/316LSS/DSS/INCONEL/According to customers’ needs) | ● /○/○/○/○/○ | ||

| Liquid level position in the machine (high _ requires heat tracing / low _ does not require heat tracing) | —/● | ||

| Output junction box(aluminum alloy /316ss) | —/— | ●/○ | ●/○ |

| Output switch (DPDT/SPDT) | —/— | ○/● | ○/● |

| Switching capacity (DC24V 3A/DC24V 5A) | —/— | ●/○ | ●/— |

| Output interface size (M20 × 1.5(F)/1/2″NPT(F)) | —/— | ●/○ | ●/— |

| Pressurized handling tools(2 full thread studs / synchronous special tools) | ●/○ | ||

| Insertion depth adjustment range (±10mm) | ● | ||

Applications of Removable Pig Signaler

In the oil and gas industry, pipelines play a crucial role in transporting and separating various hydrocarbons. These systems must maintain the highest levels of operational integrity and safety. To achieve this, operators rely on advanced technologies like removable pig signalers with DBB valves, ensuring efficient maintenance without disrupting the flow.

Transitioning to chemical processing, the situation demands similar precision. Facilities often send different chemical products through the same pipelines in batches. The integration of pig signalers and DBB valves allows for effective monitoring and isolation. This setup ensures that cross-contamination is preventable and that each batch maintains its purity.

In the realm of utilities, particularly water and wastewater management, regular inspection and maintenance are vital. These processes are critical for ensuring the quality and reliability of the service provided. Utilizing removable pig signalers with DBB valves in these pipelines helps operators detect and address issues promptly, significantly enhancing safety and efficiency.

This setup is particularly useful in scenarios where pipeline integrity, safety, and minimal operational disruption are paramount. By combining these technologies, pipeline operators can enhance both the safety and efficiency of their operations.