Description

In the intricate world of pipeline transportation systems, maintaining operational integrity while ensuring continuous flow presents significant challenges. Among the specialized tools developed to address these challenges, pig signaler emerges as a critical component in pipeline maintenance and inspection operations. As a technical expert at Shenyang Emt Piping Technology Co., Ltd., I’d like to explain the vital function these devices serve in modern pipeline management.

What Is A Pig Signaler?

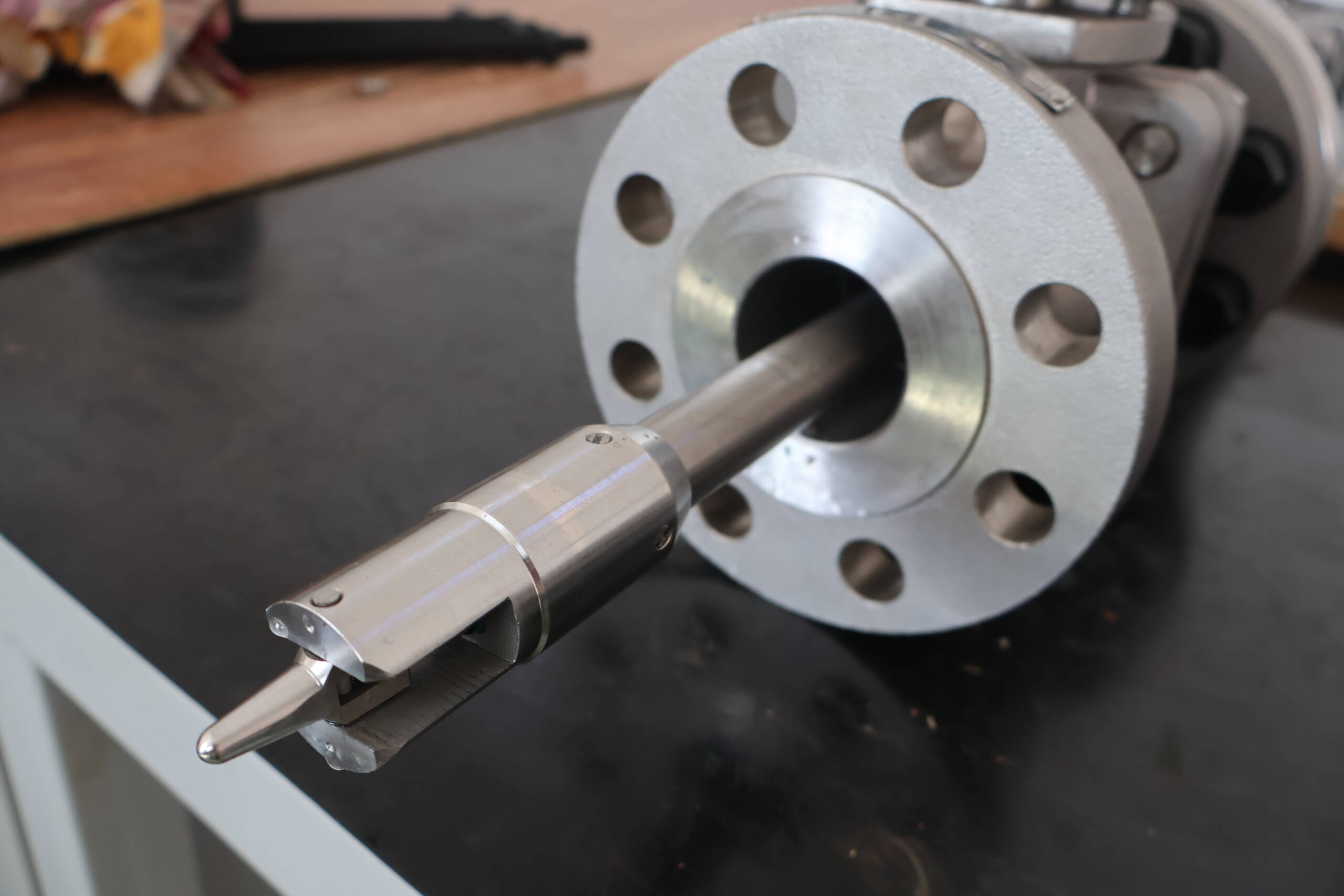

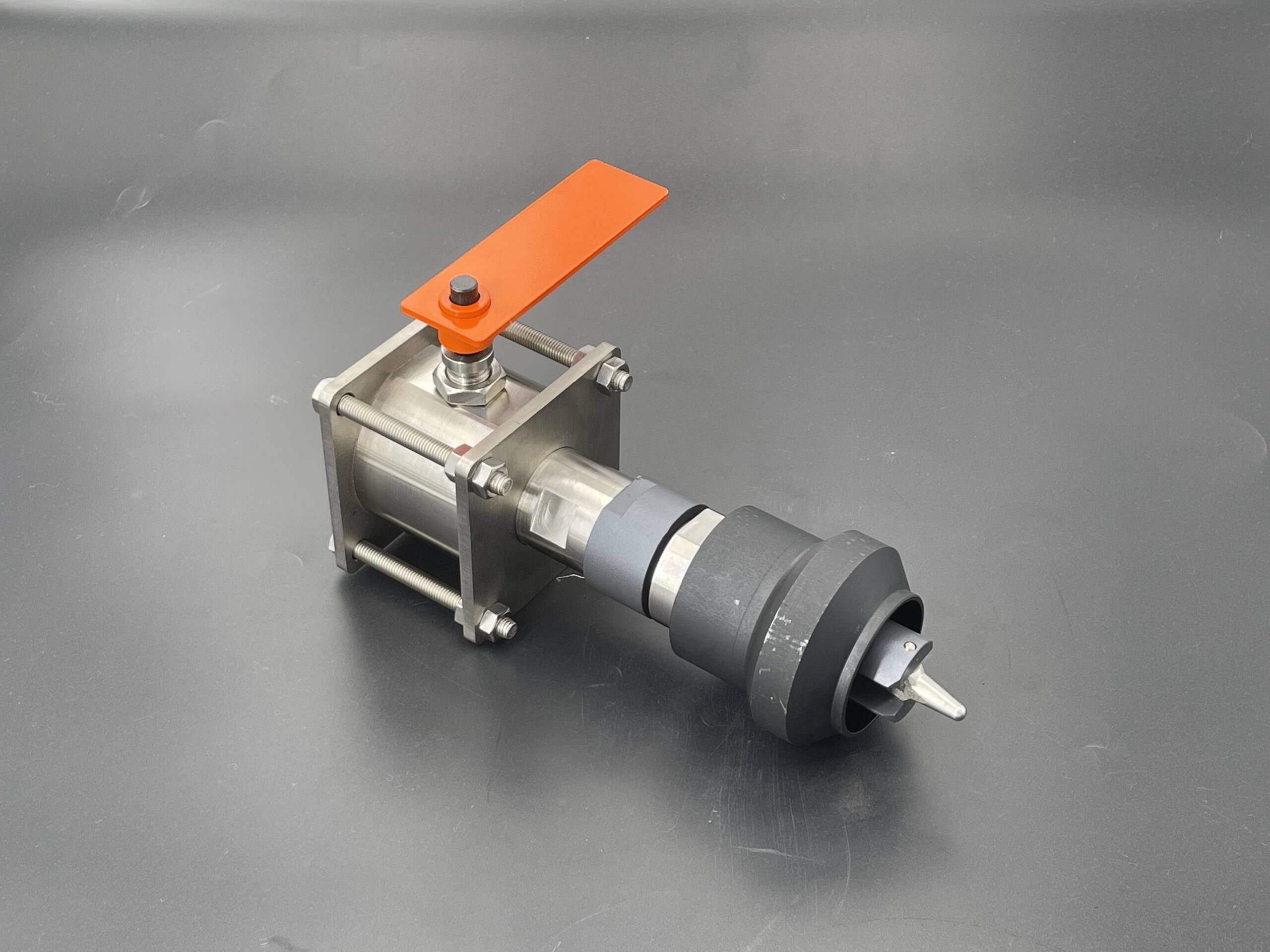

A pig signaler, or pig passage indicator, is a device installed on pipelines. It detects and signals when a pipeline inspection gauge, known as a “pig,” passes a location. The term “pig” comes from early devices that squealed like pigs when scraping pipelines.

These signalers serve multiple essential functions in pipeline operations. Primarily, they provide operators with real-time confirmation that pigs are progressing as expected through the pipeline system. This verification is crucial during cleaning operations, inspection runs, and separation processes where product batching occurs. Without reliable signaling, operators would have no way of knowing whether pigs are moving properly or if they’ve become stuck—a potentially serious operational issue.

Modern pig signalers employ various detection technologies. Mechanical signalers use physical contact with the pig to trigger a visual or electronic signal. Magnetic signalers detect the metallic components of pigs passing through the pipeline. Ultrasonic models use sound waves to detect the pig’s presence, while some advanced systems incorporate radio frequency identification (RFID) technology for more precise tracking.

Operational Significance

The operational significance of pig signalers cannot be overstated. When conducting routine pipeline maintenance, operators rely on these devices to confirm pig movement at predetermined intervals. This information allows for:

- Verification of successful pig launch and reception

- Detection of potential obstructions or restrictions

- Confirmation of pig speed and progress

- Synchronization of multi-pig operations

- Documentation of maintenance activities for regulatory compliance

In complex pipeline networks, multiple signalers create a detection system that effectively maps the pig’s journey through the system. This networked approach provides operators with comprehensive visibility into pig movement, enabling them to respond promptly to any anomalies. For instance, if a pig fails to trigger a signaler within the expected timeframe, operators can initiate troubleshooting procedures before minor issues escalate into major problems.

From a safety perspective, pig signalers contribute significantly to operational security. They help prevent over-pressurization scenarios that could occur if operators continued pumping without realizing a pig had become stuck. Additionally, in multi-product pipelines where different products are transported sequentially (a process known as batching), signalers ensure proper separation between product batches, preventing costly contamination.

Our Design to Pig Signaler

At Shenyang Emt Piping Technology Co., Ltd., we recognize that effective pipeline management requires reliable monitoring tools. Our engineering team designs pig signalers to withstand harsh operating conditions while maintaining accuracy throughout their service life. Whether installed on oil and gas transmission lines, chemical processing plants, or water distribution systems, these devices form an integral part of comprehensive pipeline integrity management programs.

As pipeline infrastructure continues to age worldwide, the importance of effective monitoring and maintenance tools like pig signalers will only increase. Their role in enabling efficient, safe, and environmentally responsible pipeline operations makes them indispensable components in the modern energy and fluid transportation landscape. For pipeline operators seeking to maximize system availability while minimizing maintenance costs and environmental risks, investing in reliable pig signaling technology represents not just good practice, but operational necessity.