Description

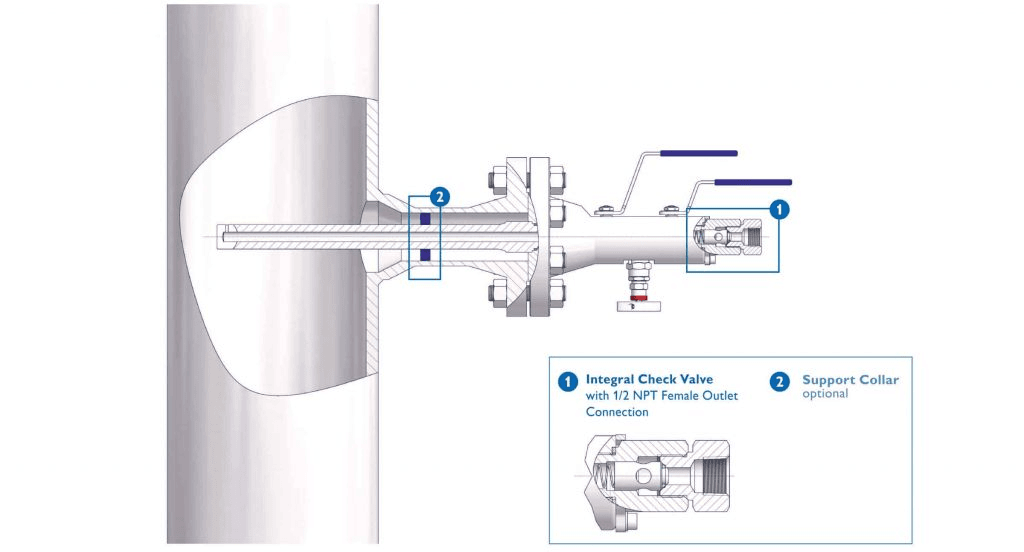

EMT high-pressure Chemical Injection Access Fitting enable safe, controlled, and easy chemical injection under full operating pressure, significantly reducing downtime. EMT provides a broad range of delivery options, from standard NPT connections to robust flanged side tees, ensuring reliable chemical injection into high-pressure systems.

A variety of injection tubes, quills, and nozzles are available to optimize delivery and dispersion based on specific application needs. And different sizes can also be customized. To safely install and retrieve injection and sampling components under operating conditions, EMT uses a Retriever and Service Valve. These tools allow for the replacement of components when injection requirements change or when maintenance is necessary—without interrupting system operations.

1. Specifications

-

Mounting

2-inch ASME (ANSI) Raised Face (RF) Flange design for seamless integration with standard industrial flanges. Welding is not required, simplifying installation and maintenance. -

Temperature Rating

-15°F (-26°C) to +400°F (+204°C) with Viton and Teflon seals, ensuring consistent performance across varied process environments. -

Pressure Rating

Rated according to flange size and class, conforming to ASME standards for safe operation under full system pressure. -

Compliance

Compliant with NACE MR0175/MR0103 for sour service applications and the Pressure Equipment Directive (PED) for use in European markets.

2. Key Benefits

-

Safe Under-Pressure Access

Install, maintain, or replace components without system shutdown. -

Corrosion-Resistant Alloys

All injection and Access Fitting are available in highly durable, corrosion-resistant materials. -

Integral Check Valve Compatibility

Can be combined with a standard integral check valve for enhanced safety. -

Robust Machined Construction

Precision-machined for reliability in high-pressure and harsh service conditions. -

Flexible Injection Options

Supports injection of a wide range of chemicals with various quill, tube, and nozzle configurations. -

ACME Threaded Option

Internal ACME threaded (AT) fittings resist clogging in processes containing solids or debris, simplifying maintenance.

3. Optional Safety Access Fitting

High-Pressure Protective Covers

Include a pressure gauge and bleed plug for secondary pressure isolation (up to 10,000 PSI), allowing safe verification and release of trapped pressure before disassembly.