Description

1. Introduction

The EMT Pig Signaller is an innovative device engineered to enhance the monitoring of pipelines. This sophisticated tool offers accurate and dependable confirmation of the passage of cleaning pigs through pipelines, which is crucial for pipeline operators. This article delves into the Removable Pig Signaller’s distinct features, types, functions, and benefits, demonstrating its effectiveness in promoting safe and efficient oil and gas transportation.

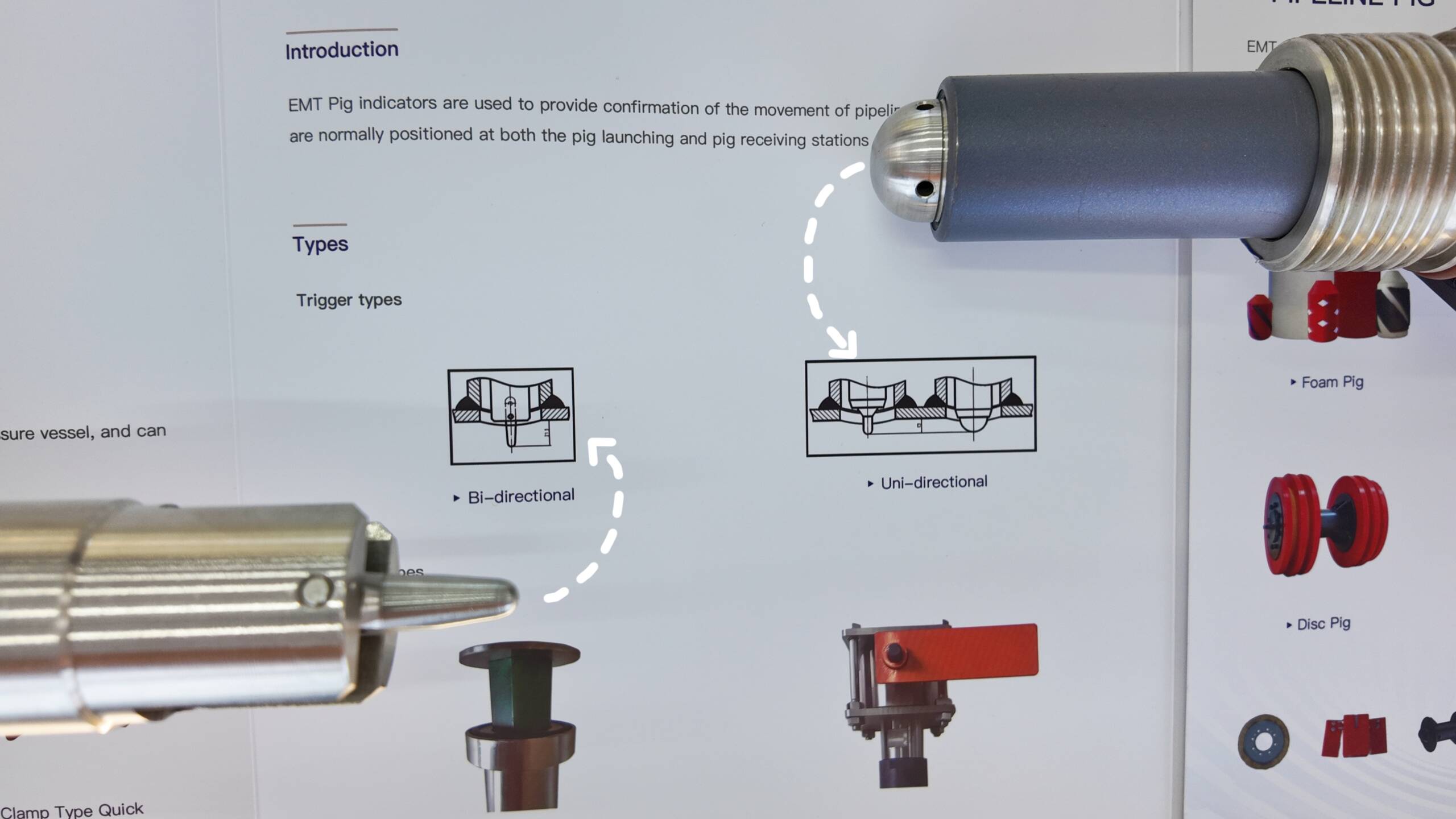

2. Types of Pig Signallers

EMT’s Removable Pig Signaller is available in various forms to meet diverse operational needs, categorized mainly by trigger and connection types:

Trigger Types:

- Bi-directional: Capable of detecting the pig’s passage irrespective of its direction of travel.

- Uni-directional: Specifically detects pig movement in a predetermined direction.

Connection Types:

- 2″ Flange Connection: Ensures a stable and secure attachment to the pipeline with a flange.

- 2″ Welded Nipple: Provides a robust, welded connection to the pipeline.

- 2″ Welded Base NPT Nipple Connection: Offers a seamless integration into the pipeline system with a welded base NPT nipple.

These devices are strategically installed at critical points such as pig launching and receiving stations to ensure comprehensive monitoring coverage.

3. Functions and Use Effects

The Removable Pig Signaller performs several vital roles in pipeline monitoring:

- Passage Detection: It detects cleaning pigs as they pass, sending real-time confirmations to operators, which is essential for monitoring the progress and ensuring the effectiveness of the pigging operation.

- Information Transmission: The device transmits important data regarding the pig’s location back to the control room, enhancing visibility and operational control over the pigging process.

- Condition Monitoring: By providing timely data, the signaller helps operators identify and address potential pipeline issues like corrosion or damage, preventing costly repairs and downtime.

The device’s detection process begins when a cleaning pig crosses a signaller-installed location, triggering an alert to the operators. This immediate feedback is critical for tracking the pig’s journey, especially in extensive or complex pipeline systems.

4. Features and Advantages of the Removable Pig Signaller

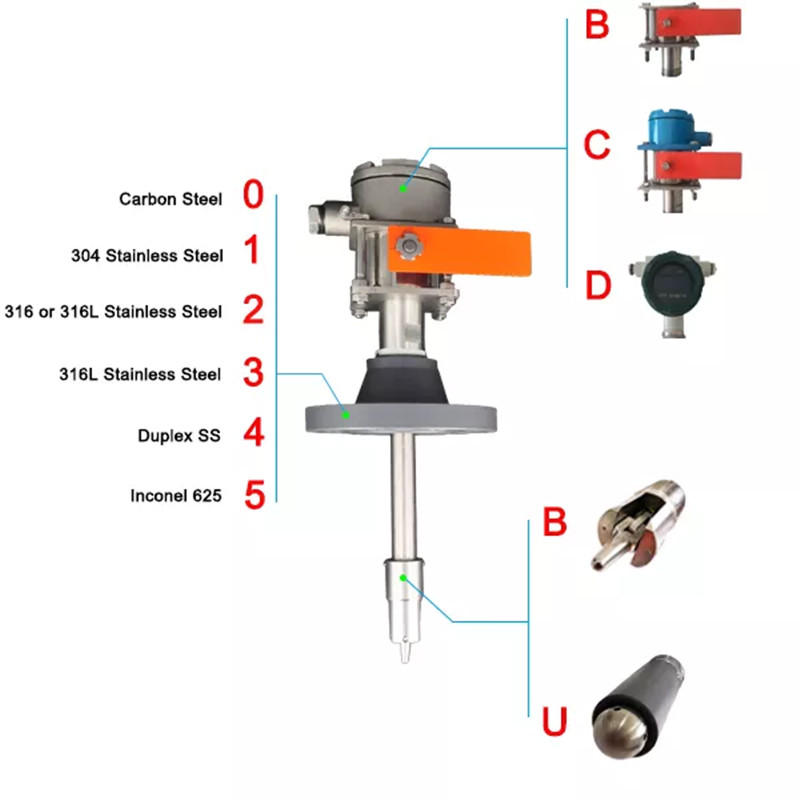

The Removable Pig Signaller from EMT offers numerous features and benefits that make it a superior choice for pipeline monitoring:

- Flange Connection: Provides a reliable seal and stability, simplifies installation and maintenance.

- Versatile Trigger Options: Available in both bi-directional and uni-directional forms, it can be adapted to different pipeline setups.

- Diverse Connection Options: With flange, welded nipple, and welded base NPT nipple connections, it ensures compatibility with various pipeline systems.

- Electrical Signal Integration: Enhances monitoring capabilities by allowing remote, real-time reporting of pig locations.

- Durable Build: Constructed from high-quality materials to endure demanding conditions, ensuring longevity and reducing maintenance needs.

- Easy Maintenance: Its removable nature facilitates quick access for repairs or replacements, minimizing operational disruptions.

- Wide Operating Temperature Range: Functions effectively across diverse environmental conditions.

- Compliance and Safety. : Meets industry safety standards and is designed to be explosion-proof, suitable for use in hazardous environments.

- Customization Options: We can customize it to meet specific operational requirements and pipeline configurations.

5. Functions and Working Principles of Pig Signaller

Passage Detection

The Removable Pig Signaller utilizes a trigger mechanism specifically designed to detect the presence and passage of a pipeline pig. This mechanism is crucial for maintaining the efficiency and safety of pipeline operations. Here’s how it functions:

- Trigger Activation: The signaller is equipped with a mechanical sensor or trigger installed at a strategic point within the pipeline. When a pig passes this point, it physically interacts with the trigger.

- Flag Indicator: This interaction causes a connected flag on the device to rotate. The flag, initially in a horizontal position, moves to an upright position. This visual cue is immediate and clearly visible, indicating that the pig has passed the designated point.

Working Principle

The working principle of the Removable Pig Signaller is straightforward yet highly effective, ensuring reliable operation even in rigorous pipeline environments:

- Mechanical Detection: The core component of the signaller is the mechanical detection system which consists of a flag linked to a trigger mechanism. As the pig moves through the pipeline, it nudges the trigger.

- Flag Movement: The physical movement of the pig against the trigger lever causes the flag to shift its position. The flag’s movement from horizontal (non-active) to vertical (active) is a direct result of this interaction.

- Visual Confirmation: Once the flag is upright, it serves as a clear, visual indication that the pig has successfully passed the signaller’s location. This is essential for operators monitoring the progress of pigging operations from a distance.

Operation Cautions

Operating the Removable Pig Signaller requires attention to certain precautions to ensure accurate results and avoid mechanical failures:

- Manual Resetting: After each detection event, the flag must be manually reset to its original horizontal position. This reset prepares the signaller for the next pig passage, ensuring continuous operational readiness.

- Flag Rotation Check: It is important to monitor the degree of flag rotation. A rotation beyond 45 degrees typically confirms the pig’s passage. However, operators must ensure that the flag does not rotate too freely or without resistance, as this might indicate a mechanical issue or improper installation.