Description

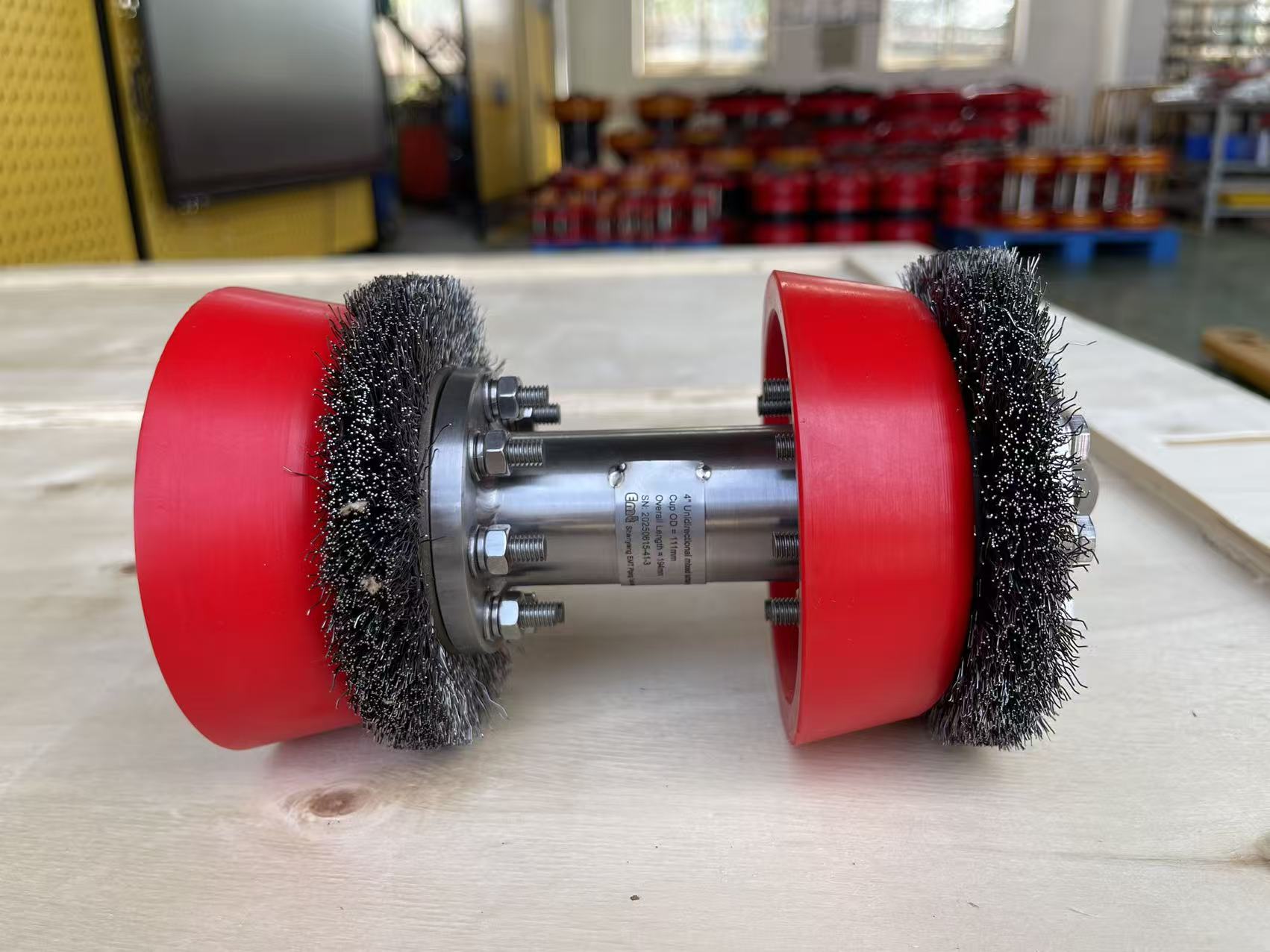

Mandrel Pig (Steel Body)

A Mandrel Pig is a type of mechanical pipeline pig that is characterized by its steel body. It is durable, customizable, and reusable, making it suitable for a wide range of pipeline operations. In particular, these pigs are commonly used in long-distance pipelines. They are especially effective for tasks such as cleaning, dewatering, gauging, and batch separation. Moreover, their robust construction allows them to withstand harsh pipeline conditions, thereby enhancing operational efficiency and reliability.

Key Features of Mandrel Pig

- Steel Body (Mandrel): Designed to withstand high pressures and tough pipeline conditions.

- Modular Design: Discs, cups, brushes, and scrapers are bolted to the body and can be replaced or customized.

- Multiple Configurations: Can be built for cleaning, sealing, gauging, or specialized applications.

- Tracking Compatibility: Can be fitted with transmitters, magnets, or radio-frequency devices for pig tracking and locating.

Components of a Mandrel Pig

| Component | Description |

|---|---|

| Mandrel Body | Main steel shaft that holds all other components. |

| Sealing Cups/Discs | Urethane or rubber elements that create a seal with the pipeline wall. |

| Brushes/Scrapers (Optional) | For removing debris, scale, or wax. |

| Bypass Ports (Optional) | Can be added to allow limited product flow through the pig. |

| Nose Cone or Bumper | Front end to reduce impact and guide the pig around bends. |

| Transmitter Housing | For tracking equipment or data loggers. |

Common Applications

- Pipeline Cleaning: Removes debris, scale, wax, or corrosion products.

- Liquid Removal/Dewatering: Clears water or other liquids post-hydrotesting.

- Batch Separation: Separates different products in a multiproduct pipeline.

- Gauging: Ensures consistent internal diameter of a pipeline.

- Pre-Inspection Runs: Used before intelligent pigs to clear and assess the line.

Advntages

- Heavy-duty and long-lasting: Ideal for extended use and harsh environments.

- Customizable: Easily configured for specific tasks.

- Efficient sealing: Cups and discs provide strong, consistent contact with pipe wall.

- Reusable: You can replace the components, reducing long-term costs.

Considerations

- Heavier than foam pigs: Requires more launching and retrieval force.

- Not suitable for tight bends or small-diameter piping.

- Higher upfront cost, but offset by durability and reusability.

Typical Uses in Industry

- Oil & Gas: Crude oil, gas, and product pipelines.

- Petrochemical: Chemical line cleaning and separation.

- Water Pipelines: For cleaning and inspection readiness.

- Hydrotesting Support: Used before and after hydrostatic testing.

Types of Mandrel Pigs

| Type | Description |

|---|---|

| Cup Pig | Uses polyurethane cups for sealing and movement. |

| Disc Pig | Uses flat discs that apply pressure against pipe wall. |

| Brush Pig | Includes wire or plastic brushes for aggressive cleaning. |

| Combo Pig | Combines cups, discs, and brushes for multi-functionality. |

Conclusion

A Mandrel Pig with a steel body is a robust and adaptable tool for maintaining pipeline integrity and cleanliness. Due to its sturdy construction and customizable design, it is especially suitable for demanding pigging operations across various industries. Furthermore, its durability allows it to perform effectively under harsh conditions. As a result, it is a preferred choice for operators seeking long-term, reliable solutions. In addition, its flexibility makes it ideal for a wide range of applications, from cleaning to product separation.