Description

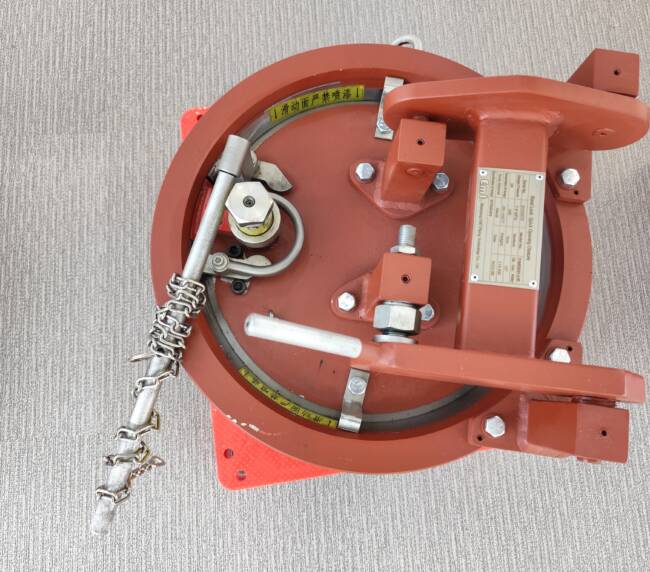

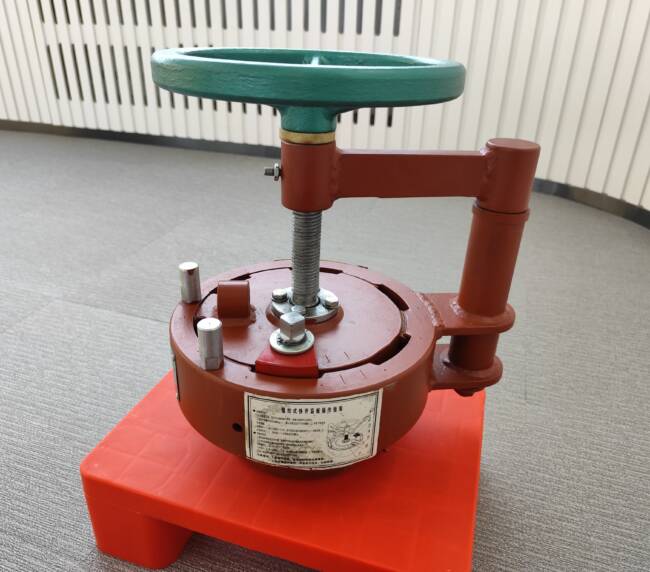

The EMT Quick Opening End Closure is a highly efficient and safe solution designed for a variety of industrial applications including oil and gas pipeline pigging, energy, mining, and construction. Manufactured by EMT Pigging and originating from Liaoning, China, this product is engineered to provide a reliable and cost-effective method for accessing pipeline systems.

1. Data Sheet for EMT Quick Opening End Closure

Below is a detailed specification sheet for the EMT Quick Opening End Closure, designed for efficient and safe use in high-demand industrial environments such as oil & gas pipelines and other related applications.

| Parameter | Specification |

|---|---|

| Product Name | EMT Horizontal/Vertical Type Quick Opening End Closure |

| Brand Name | EMT Pigging |

| Type | Available in Vertical and Horizontal configurations |

| Applicable Industries | Building Material Shops, Construction Works, Energy & Mining, Pipeline Pigging, Oil & Gas Pipeline |

| Weight (KG) | 10 |

| Single Package Size | 60 x 60 x 20 cm |

| Single Gross Weight | 12.000 kg |

| Showroom Location | None |

| Video Outgoing-Inspection | Provided |

| Machinery Test Report | Provided |

| Place of Origin | Liaoning, China |

| Warranty | 1.5 years |

| Condition | New |

| Feature | Long life and Low cost |

| Application | Industry-specific for Oil & Gas Pipeline Cleaning |

| Size | Customized |

| Port | Dalian, China |

| Minimum Order Quantity (MOQ) | 1 Set |

| Material | Customized |

| Certification | ISO 9001 |

| Design Pressure | 1.6MPa – 30MPa |

| Corrosion Allowance | 2 mm |

| Seismic Fortification Intensity | 7 Degrees |

| Work Medium | Oil, Natural gas, Water, and Ore Pulp etc. |

| Opening Time | Within 60 seconds with less than 200N force |

| Opening Type | Vertical or Horizontal |

2. Industry-Specific Design Attributes

- Applicable Industries. This closure system is ideal for use in building material shops, construction sites, and the energy and mining sectors, particularly for tasks like pipeline pigging and maintenance in oil and gas pipelines.

- Port of Shipment: Dalian, China

- Minimum Order Quantity: 1 Set

- Certifications: ISO 9001 certified, ensuring compliance with international quality standards.

3. Advanced Features of EMT Quick Opening End Closure

The EMT Quick Opening End Closure provides a range of advanced features tailored to enhance operational efficiency, safety, and reliability in high-pressure environments. Here’s a detailed exploration of these advanced characteristics:

Short Operating Time

- Locking-Ring Mechanism. This feature includes an innovative locking-ring mechanism that drastically shortens the time required for opening and closing. The design is optimized to facilitate quick access, ensuring that operational downtime is minimized.

- Ease of Operation. We can operate the closure with less than 200N of force, making it possible for a single operator to manage the process efficiently. This ease of operation is critical in high-throughput industries where time savings translate directly into cost savings.

- Rapid Access. The quick operational capability is particularly beneficial during emergency situations or routine maintenance checks, where fast and reliable access to the pipeline is necessary.

Safety Enhancements

- Self-Tightening Lip Seal. This unique sealing design not only ensures a tight and secure closure but also enhances the overall integrity of the seal as internal pressures increase. The self-tightening feature means that the seal’s effectiveness is maintained even under varying pressure conditions, reducing the risk of leaks.

- Safety Lock System. The closure is equipped with a robust safety lock system that includes a self-locking function, which is crucial for preventing the accidental opening of the closure while under pressure. This feature ensures that the closure can only be opened when it is safe to do so, thereby protecting the operating personnel and the environment.

- Pressure and Leak Prevention. By integrating these safety mechanisms, the closure helps prevent accidents and leaks. They are critical concerns in industries dealing with hazardous materials.

Pressure Management

- Design Pressure Range. We can engineer it to withstand a wide range of design pressures, from 1.6MPa to 30MPa. This makes it versatile enough to work in various applications, from low-pressure municipal systems to high-pressure extraction or processing operations.

- Corrosion Allowance. With a 2mm corrosion allowance, the closure offers an added layer of durability against the corrosive elements that are often present in industrial environments. This feature extends the lifespan of the closure and reduces maintenance needs.

- Seismic Fortification. Rated for seismic activities up to 7 degrees of fortification intensity, the EMT Quick Opening End Closure is suitable for use in geographically volatile areas where seismic activity may impact operational integrity. This feature ensures that even in the event of such disturbances, the structural integrity and functional capabilities of the closure remain uncompromised.

Operational Safety

- Dual Pressure Relief System. Ensures complete depressurization of the container’s interior before the blind flange cover is opened, minimizing the risk of accidents due to improper handling or operational errors.

4. Performance and Durability

- Long Lifespan and Low Maintenance Costs:

Constructed to offer longevity and reliability, which helps reduce downtime and maintenance expenses over its operational life.

- Warranty:

Comes with a 1.5-year warranty, highlighting the manufacturer’s confidence in its durability and performance.

5. Our Service

2. We offer the samples to attest to the quality and our services.

3. The fastest feedback!

4. The fastest delivery time.

5.24 hours,7 days online.