Description

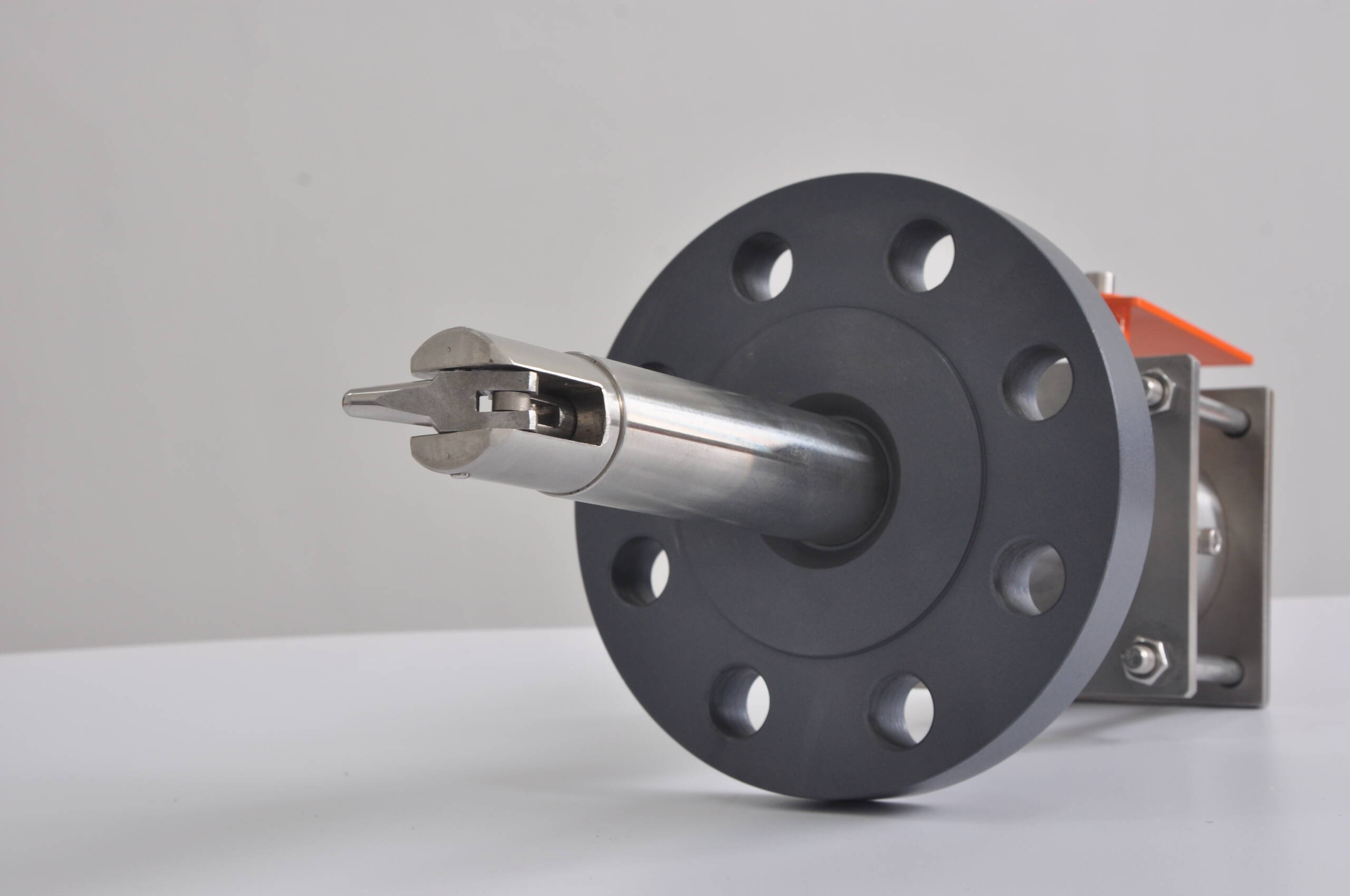

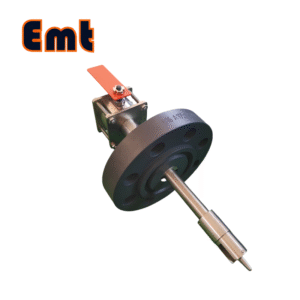

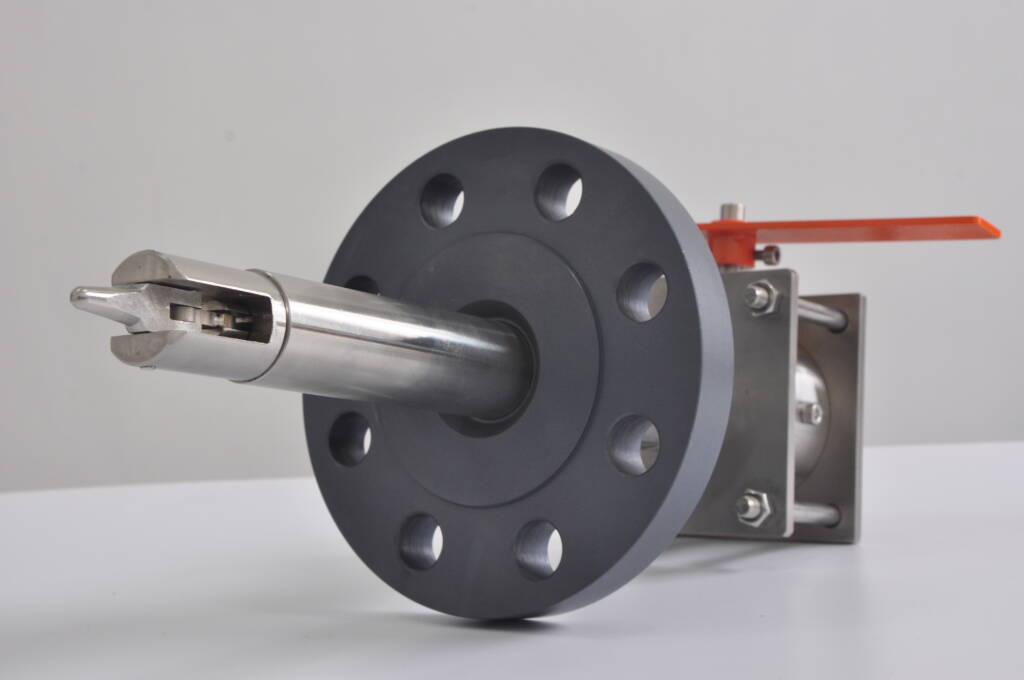

EMT-Magnetic Pig Signaller is engineered to provide that absolute certainty. Designed for durability, ease of installation, and unwavering accuracy, this detector is the robust and reliable solution for operators.

EMT Magnetic Pig Signaller acts as a trigger point, offering positive confirmation that a pig has passed a specific location—be it at the launch/receive station or a critical intermediate point along the route.

-

Verifying the successful launch and receipt of pigs.

-

Tracking pig progress during cleaning or batching operations.

-

Pinpointing the location of a stuck pig to facilitate efficient remediation.

-

Providing a trigger for other system functions, such as valve sequencing or data logging.

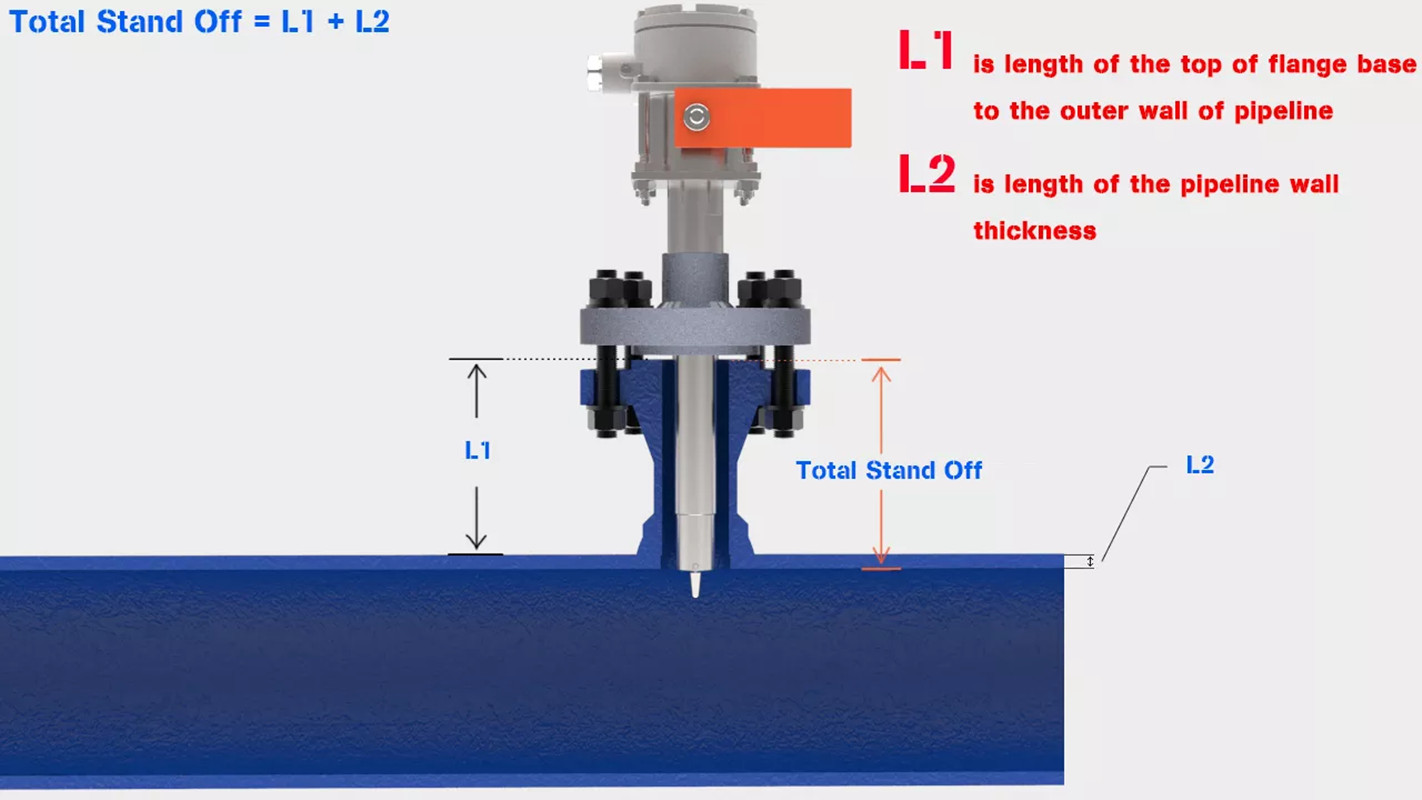

1. Technical Specifications of Magnetic Pig Signaller

We believe in transparency and performance-backed claims. The EMT Flange Pig Detector is specified to deliver in the most demanding conditions.

-

Primary Mounting: 2″ Flange Connection (ANSII Class 150/300 standard, others available).

-

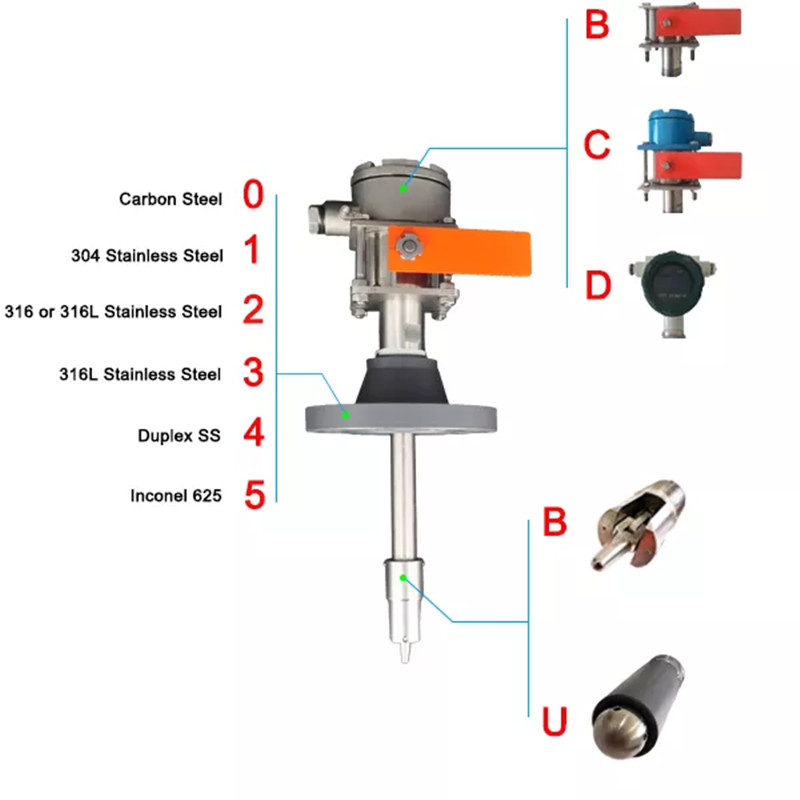

Materials of Construction: To ensure compatibility with your specific media and external environment, we offer a selection of high-performance materials:

-

Stainless Steel 304 (Standard)

-

Stainless Steel 316 (Enhanced Corrosion Resistance)

-

Duplex Stainless Steel (DSS F51) (For high-chloride environments)

-

Carbon Steel A105N (For non-corrosive services)

-

Inconel 625 (For extreme corrosion and temperature applications)

-

-

Operating Temperature Range: -20°C to +120°C.

-

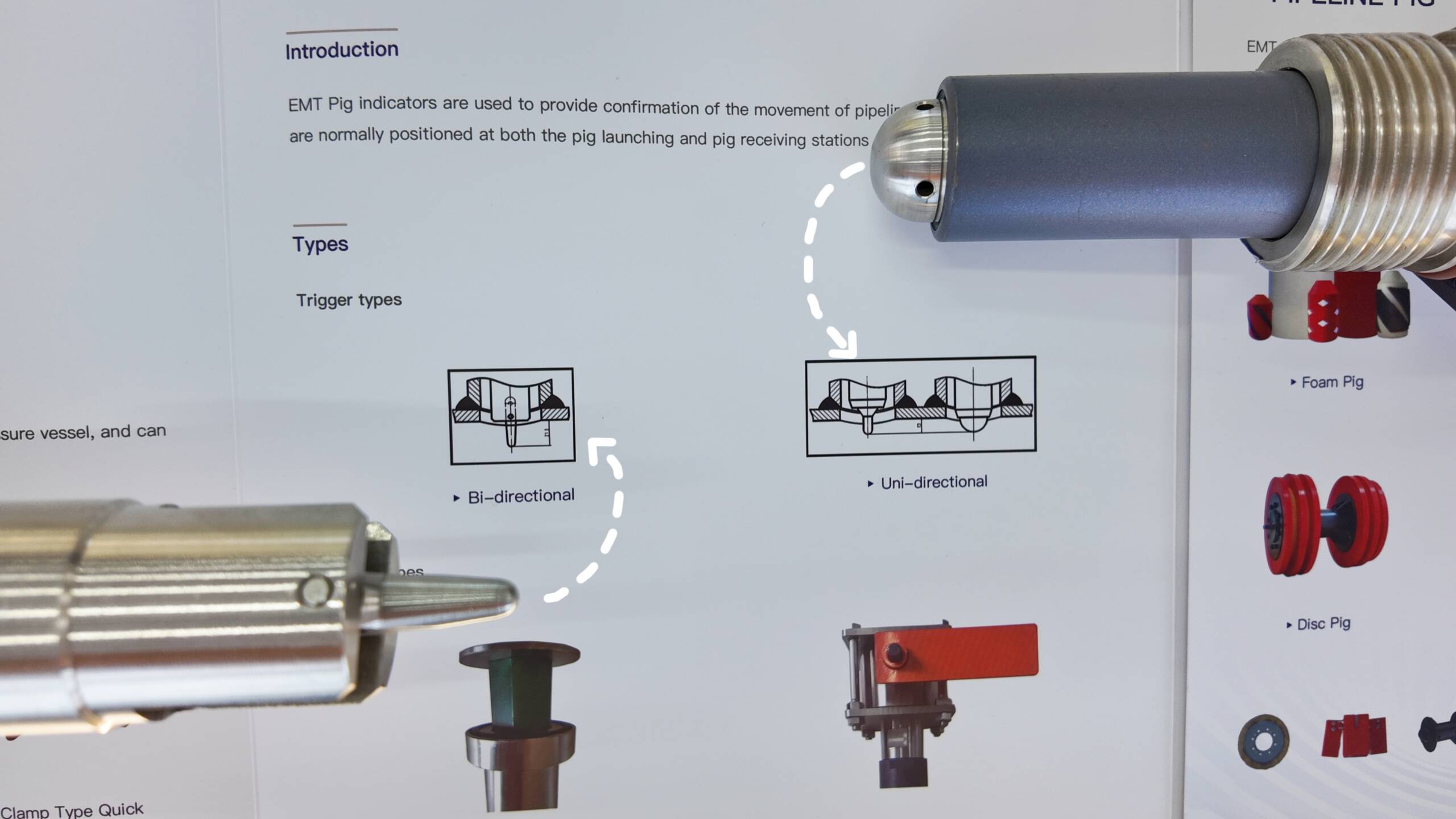

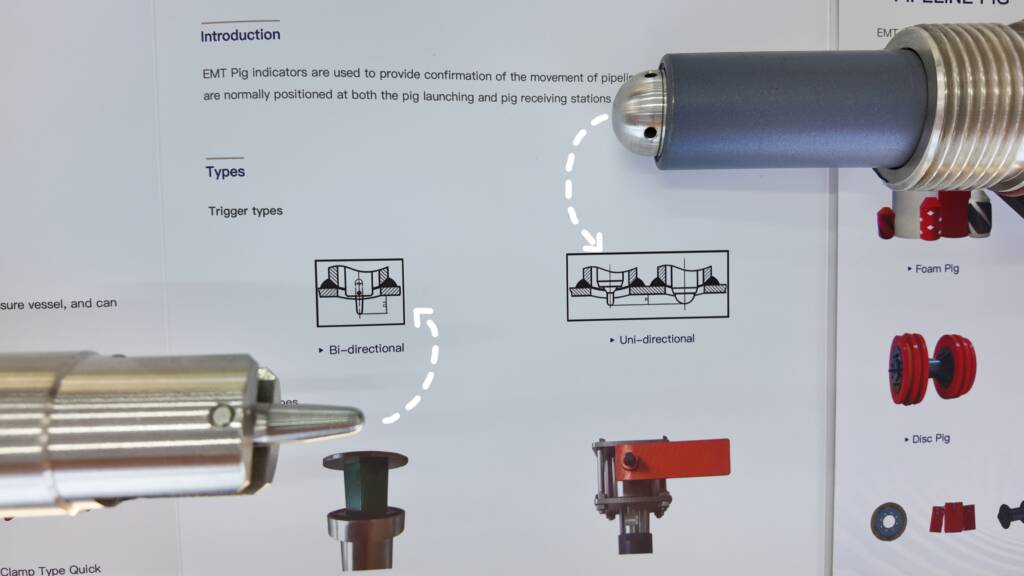

Trigger Mechanisms: We offer versatility to match your pipeline’s flow characteristics:

-

-

Bi-directional: For pipelines requiring pigging in both directions.

-

Bi-directional Feather: A sensitive variant to prevent false triggers in systems with variable flow, while still detecting pigs moving in either direction.

-

Uni-directional: A cost-effective and simple solution for one-way pipelines.

-

2. Why Choose Us

3. Applications Across Industries

The EMT Flange Pig Detector is versatile enough for a wide range of applications, including:

-

Oil & Gas Transmission Pipelines

-

Petrochemical and Refining Plants

-

Water and Wastewater Pipelines

-

Food and Beverage Processing Lines