Description

Introduction

In modern pipeline operations, the ability to adapt to varying flow conditions is essential for maintaining efficiency. EMT’s Bidirectional Pig series addresses this need through practical engineering, delivering effective cleaning performance in both flow directions without requiring reconfiguration. These pigs provide a practical solution for pipeline maintenance challenges, offering reliable performance where flow direction may change or remain unpredictable.

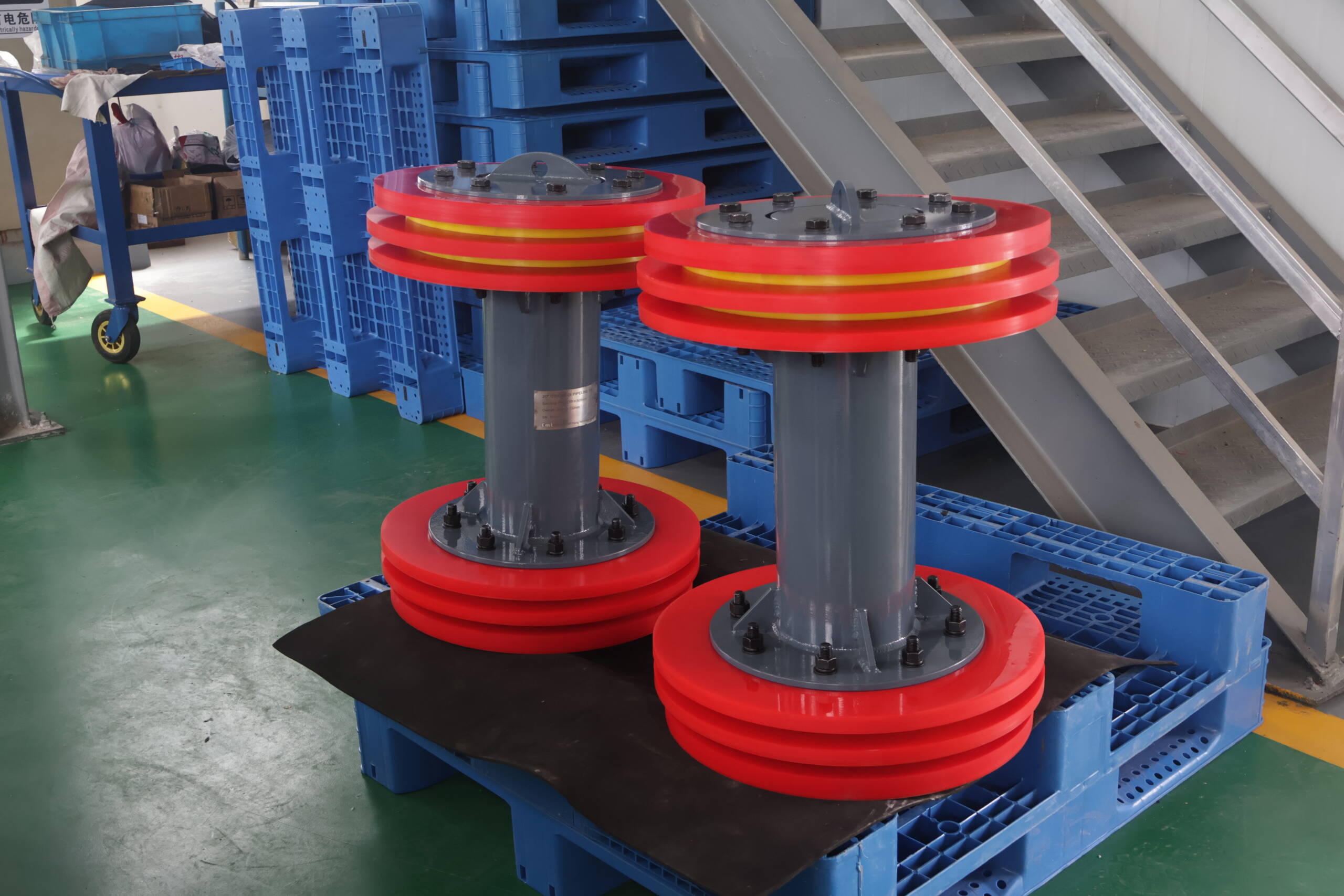

Developed for operators handling liquid product batching, debris removal, or routine maintenance in pipelines with bidirectional flow requirements, these pigs maintain consistent cleaning effectiveness where traditional unidirectional designs would require retrieval and reorientation. Their symmetrical construction and balanced design ensure stable movement and proper sealing regardless of flow direction, making them suitable for pipelines with reversing flow patterns or complex network configurations.

Technical Specifications

Core Construction:

-

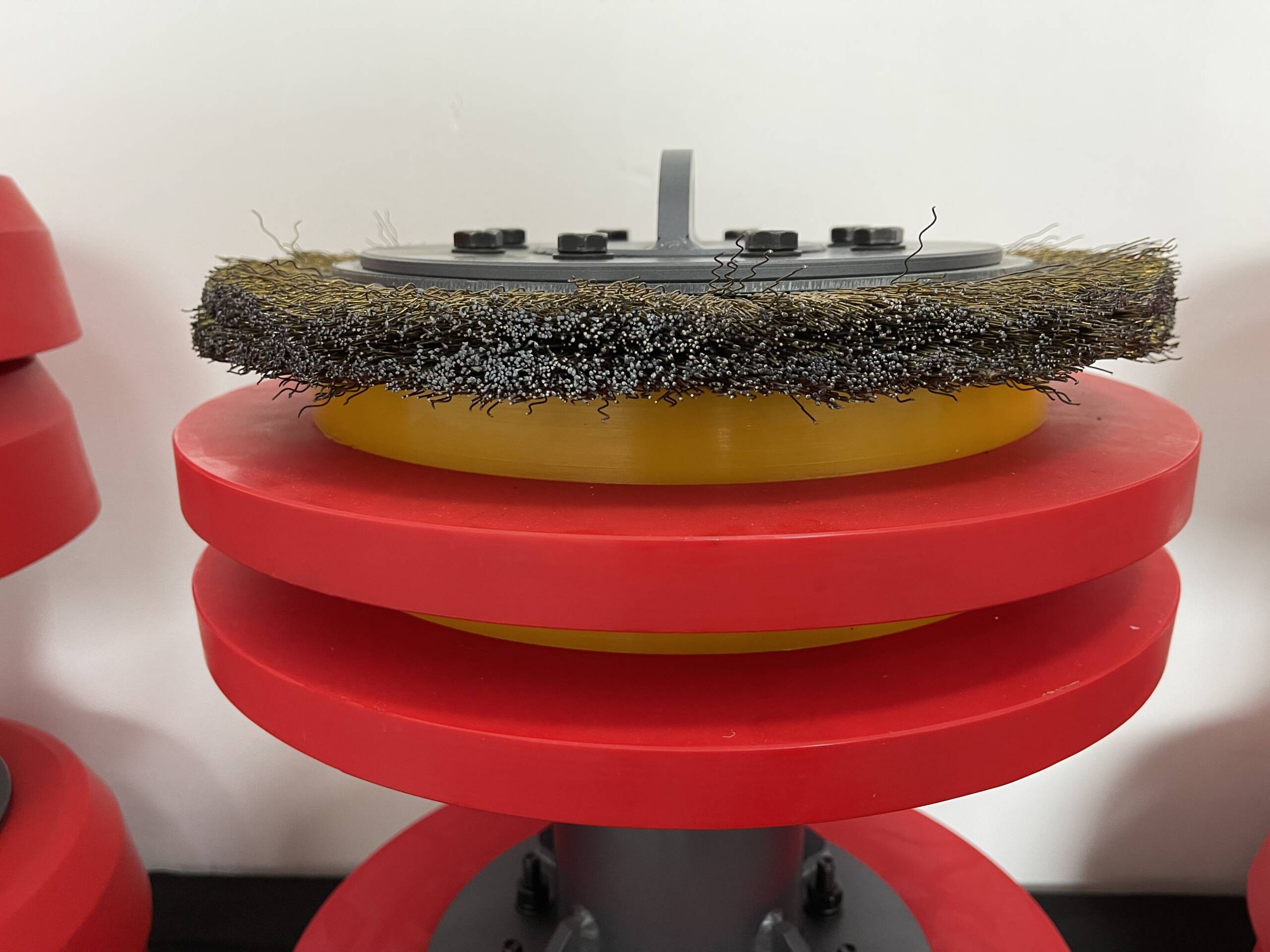

Cup Material: High-grade polyurethane formulated for exceptional abrasion resistance and flexibility

-

Body Material: Reinforced carbon steel core providing structural integrity under extreme operating conditions

-

Temperature Range: -40°C to +120°C operational capability

-

Size Spectrum: 2 inches to 60 inches diameter

-

Design Feature: Symmetrical construction enabling equal performance in both flow directions

Why Bidirectional Pig Design Matters:

Traditional unidirectional pigs require careful orientation and cannot reverse direction without jamming risk. Our bidirectional pigs eliminate this limitation through:

-

Identical leading and trailing cups that maintain sealing pressure in either direction

-

Balanced structural design that prevents rotation-related issues

-

Consistent cleaning effectiveness regardless of flow direction changes

Key Advantages of EMT Bidirectional Pigs

1. Operational Flexibility

-

Execute cleaning programs without flow direction constraints

-

Perfect for complex pipeline networks with multiple injection points

-

Handle unexpected flow reversals without pig retrieval or reorientation

-

Reduce operational planning complexity and scheduling constraints

2. Superior Sealing Performance

The polyurethane cups maintain continuous contact with pipeline walls through:

-

Optimal cup durometer selection for specific application needs

-

Progressive cup design that adapts to pipeline diameter variations

-

Maintains effective sealing through bends, reductions, and ovality

3. Enhanced Durability

-

Polyurethane formulation tested to withstand 1,000+ operating hours

-

Carbon steel skeleton engineered for impact resistance

-

Minimum 3-year service life under normal operating conditions

-

Resistance to common pipeline chemicals including hydrocarbons, inhibitors, and brine

4. Cost Efficiency

-

Reduce pig inventory requirements by up to 40% compared to unidirectional alternatives

-

Minimize operational downtime during flow direction changes

-

Lower retrieval and reinstallation costs

-

Extended service life reduces replacement frequency

Industry Applications

Oil & Gas Pipelines:

-

Crude oil pipeline wax removal and batch separation

-

Natural gas pipeline liquid removal and debris cleaning

-

Refinery and petrochemical plant internal cleaning

-

Pipeline commissioning and decommissioning operations

Water Management:

-

Potable water pipeline biofilm and sediment removal

-

Wastewater pipeline scaling prevention and cleaning

-

Municipal water distribution system maintenance

Industrial Applications:

-

Chemical processing line product separation and cleaning

-

Power plant cooling water system maintenance

-

Mining slurry pipeline wear protection and cleaning

Why Choose EMT Bidirectional Pigs?

-

Proven Reliability: Over 15,000 successful runs documented worldwide

-

Technical Superiority: Patented cup design ensures consistent performance

-

Custom Engineering: Solutions tailored to your specific pipeline characteristics

-

Global Support: 24/7 technical assistance and emergency response

-

Quality Assurance: ISO 9001 certified manufacturing with full traceability