Description

Corrosion Coupons

One of the most straightforward and time-tested methods for estimating corrosion losses—especially from pitting—in pipelines is the use of corrosion coupons and weight loss analysis. Technicians pre-weigh a corrosion coupon made from the same or similar material as the pipeline. They insert the coupon into the pipeline system and leave it in place for a specific period. After exposure, they remove the coupon, visually inspect it, clean off any corrosion by-products, and reweigh it. They then calculate the total material loss by comparing the original and final weights, using this data to determine the pipeline’s average corrosion rate. Coupons come in various designs, such as flush discs, multiple discs, strip coupons, and ladder coupons, depending on the application and monitoring needs.

Device Constitution

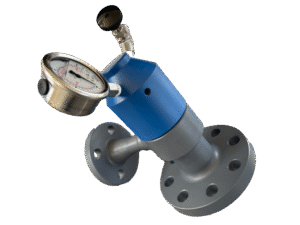

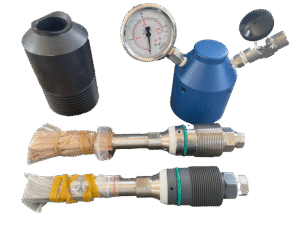

The EMT Hydraulic Corrosion Coupon is composed of a base, protective cover, insertion body, coupon nut, coupon holder, coupons, and other accessories.

The base types can be divided into welded type and flanged type. Protective covers can be divided into protective covers without gauge valve and protective covers with gauge valve.

Main Parameters

Operating temperature: -70~120℃.

Operating pressure: 0~68.9MPa.

Coupon Holder: Stationary & adjustable plunging length

Strip Type: suitable for mounting of strip coupon

Disk Type: suitable for mounting of plane disk coupon without interfering with pipeline cleaning.

Coupon Specifications:

(1) 3″ ×1/2″ ×1/16″

(2) 3″ ×1/2″ ×1/8″

(3) 3″ ×1″ ×1/16″

(4) 3″ ×1″ ×1/8″

(5) φ31.8×3.2(1.25″ ×1/8″ )

Corrosion Coupon Installation Method

The installation methods can be divided into the following two types according to the type of base:

Flange type: Specification is 2″ RF or RJ, subject to ANSI or API standard.

Welding type: Specification is 2″.

Welded Base Corrosion Coupon

Prepare the pre-assembled corrosion coupon and ensure the integrity of seals and tightness of screws.

Weld the base onto the pipeline.

Verify the condition of the O-ring on the locking pin. Ensure the pin’s tail is flush with the base surface.

Install the integrated coupon insertion assembly onto the welded base. Align the coupon width direction with the medium flow direction to minimize resistance.

Tighten the locking pin onto the base.

Finally tighten the protective cover.

Flange Base Corrosion Coupon

Install the flange base of the device onto the installation flange on the pipeline.

Check if the sealing ring on the locking pin is intact. Before installation, check the position of the locking pin to ensure that its tail is flush with the outer surface of the base.

Install the integrated coupon insertion assembly onto the welded base. Align the coupon width direction with the medium flow direction to minimize resistance.

Tighten the locking pin onto the base.

Finally, tighten the protective cover.