Description

What are Dewatering Pigs?

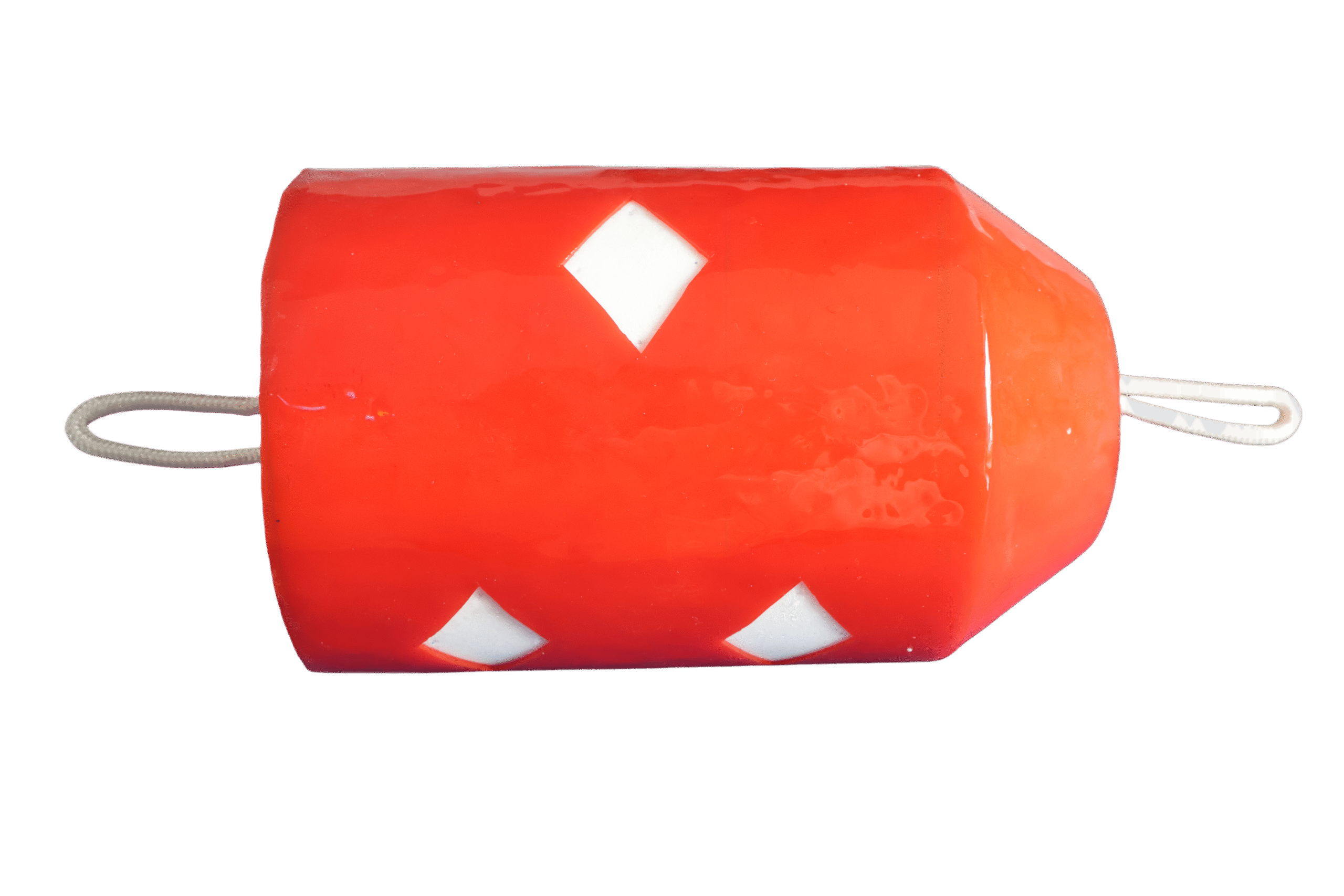

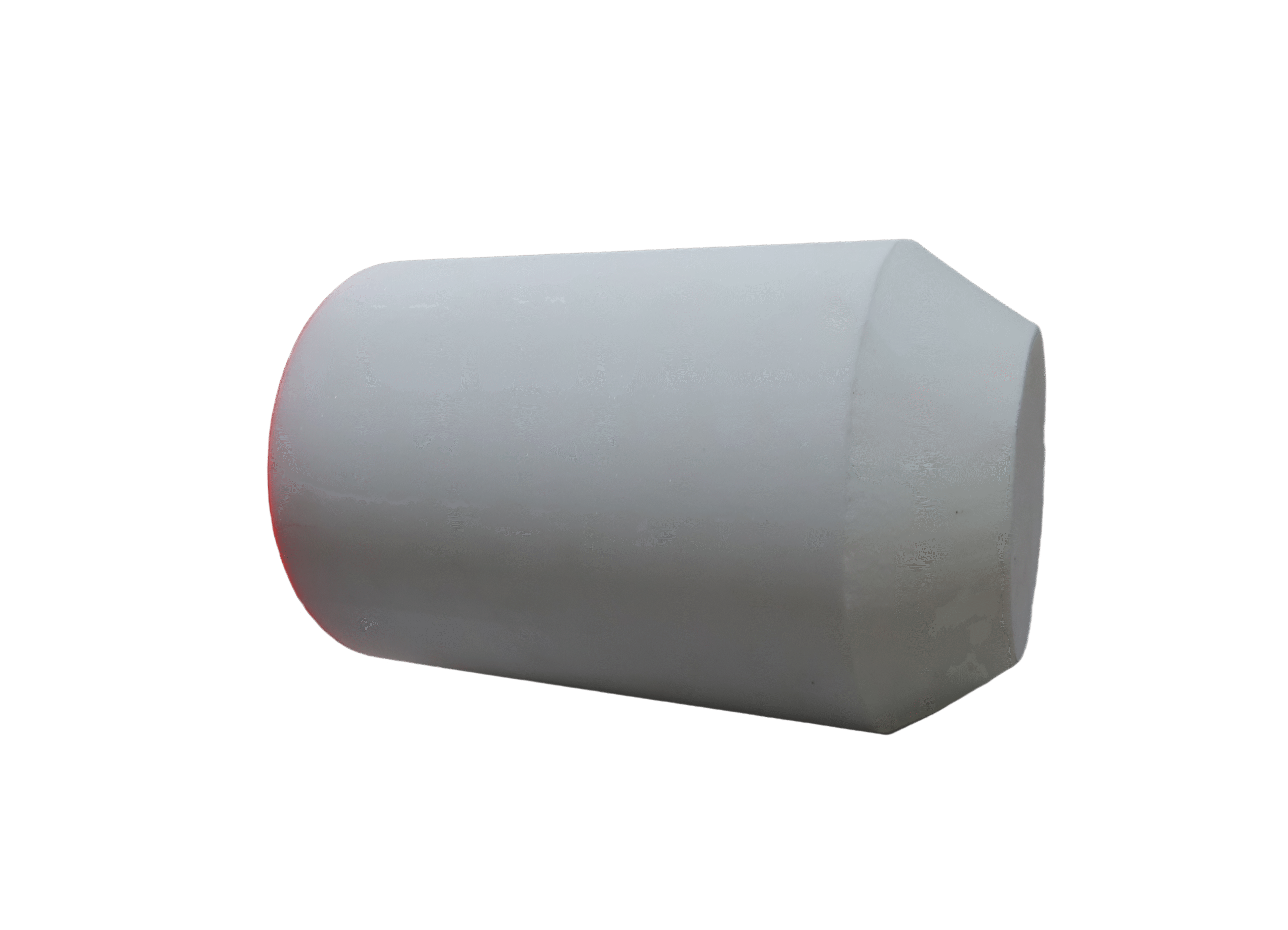

Dewatering pigs are devices designed to travel through pipelines for the purpose of removing accumulated water and debris. They are typically cylindrical or spherical and are made from materials such as foam, rubber, or polymers that can adapt to the internal diameter of the pipeline. These pigs may also have scraping edges to physically remove debris or coatings from the pipe interior.

The Dewatering Process Explained

Preparing the Pipeline for Dewatering

To begin, technicians halt the flow of the pipeline and isolate the section slated for dewatering. This preparation step ensures that the environment is safe and controlled for the operation.

Stages of a Dewatering Operation

The dewatering process starts with operators inserting a dewatering pig into the pipeline at a designated entry point. They then pressurize the pipeline, which propels the pig through it. As the pig moves along, it expels water and debris from the pipeline.

Post-Dewatering Actions

After finishing the dewatering operation, crews carry out an internal inspection of the pipeline. They evaluate how effectively the pig has cleaned the pipeline. Once satisfied with the cleanliness and integrity, they return the pipeline to its normal operational status.

Dewatering Pigs in Pipeline Maintenance

Dewatering pigs are specialized tools used in the maintenance and operation of pipelines, particularly in the oil, gas, and water industries. Their primary function is to remove water from pipelines, which is crucial for preventing corrosion and preparing the pipeline for further processes like inspection or maintenance. Here’s a closer look at what dewatering pigs are, how they work, and their benefits.

How Do Dewatering Pigs Work?

The working principle of dewatering pigs involves:

Insertion: Operators insert the pig into the pipeline at a pig launcher, a specialized launching facility.

Propulsion: Operators insert the pig into the pipeline. They push it through using a pressure differential. This differential is created by the pipeline’s pump system. Alternatively, air or a less viscous fluid can propel the pig.

Cleaning and Pushing: As the pig travels, it pushes water and debris. Moreover, its design conforms to the pipeline’s shape. This ensures it scrapes the walls clean. As a result, it effectively removes moisture and sedimentation from the pipeline. In the extraction phase, the pig travels through the designated pipeline section. Once it completes its journey, it reaches a pig receiver. This facility is specifically designed for safely removing the pig. Finally, the pig is extracted from the pipeline.

Benefits of Using Dewatering Pigs

The use of dewatering pigs offers several advantages:

Corrosion Prevention: By removing water from pipelines, dewatering pigs help prevent corrosion, which can lead to pipeline failures and leaks.

Increased Efficiency: Dry pipelines are essential for the efficient transport of gas and oil, as water can cause flow issues and increase the risk of hydrate formation.

Cost-Effective Maintenance: Regular use of dewatering pigs can reduce the need for costly chemical treatments and more invasive mechanical cleaning methods.

Enhanced Safety: Maintaining a clean and dry pipeline reduces the risk of pipeline blockages and the associated safety hazards.

Dewatering pigs are thus critical components in the preventive maintenance schedule of pipelines, ensuring their longevity, efficiency, and safety.

Installation and Operation

Step-by-Step Guide to Installing Dewatering Pigs

Initial Inspection

The installation process begins with a thorough inspection of the pipeline. This critical step involves checking for any damages or blockages which could impact the effectiveness of the dewatering pig. After ensuring the pipeline’s integrity, you should select the most appropriate type and size of the dewatering pig. This decision should be based on factors such as the pipeline’s diameter and the fluid characteristics it carries.

Preparation of the Pig Launcher

Once the appropriate pig has been selected, the next step is to prepare the pig launcher. This device is essential for inserting the pig into the pipeline. Start by thoroughly cleaning the launcher to eliminate any debris that might obstruct the pig’s insertion. Following the cleaning, carefully place the dewatering pig into the launcher, making sure to align it correctly with the pipeline’s flow direction.

Securing and Pressurizing the Launcher

After positioning the pig, securely close the launcher’s trap door to safely encase the pig inside. Following this step, it is crucial to check all connections to the launcher to ensure they are tight and free from leaks. The final step in the preparation phase is to pressurize the launcher to the required level, thereby initiating the dewatering process. Throughout this process, continuously monitor the pressure to maintain a steady flow and ensure the operation runs smoothly.

Best Practices for Operating Dewatering Pigs

Adhere strictly to the manufacturer’s guidelines concerning pressure settings and operational speeds to ensure effective operation. Start the dewatering process slowly, allowing the pig to adapt to the conditions within the pipeline.

Maintain clear communication with your team during the operation to ensure all members are aware of their responsibilities and can quickly react to any operational changes. Once the pig has completed its course, carefully depressurize the system before opening the receiver to remove the pig.

.gif)

.gif)