Description

Introduction to EMT’s Brush Pig

The EMT Brush Pig, also known as a pipeline brush pig or polyurethane scraper cup pig with magnetic brushes, is an essential tool for maintaining and operating pipelines across various industries. Constructed from durable materials like polyurethane, this device plays a critical role in cleaning and inspecting pipeline systems, ensuring their efficiency, safety, and longevity.

Brush pigs are designed to perform multiple functions, including cleaning, gauging, and maintaining pipelines. They are particularly valuable in industries such as oil and gas, mining, construction, and energy, where pipeline integrity is essential for safe and efficient operations. The primary purpose of the brush pig is to remove debris, buildup, and other obstructions from inside the pipeline. By doing so, it prevents blockages, reduces the risk of corrosion, and helps maintain the structural integrity of the pipeline over time.

EMT, a trusted leader in pipeline solutions, has developed this advanced tool to ensure efficient and reliable cleaning and maintenance for a wide range of industries. Whether in oil and gas, mining, or construction, EMT’s Brush Pig is a vital component in maintaining pipeline performance and durability.

Design and Features of EMT’s Brush Pig

The EMT Brush Pig features a durable construction made from high-quality polyurethane. This material provides exceptional resistance to wear and tear, even in demanding conditions. Additionally, the polyurethane ensures durability and resilience, allowing the brush pig to operate efficiently in medium temperatures ranging from -40°C to 120°C. This robust design makes it suitable for challenging environments in industries like oil, gas, and energy.

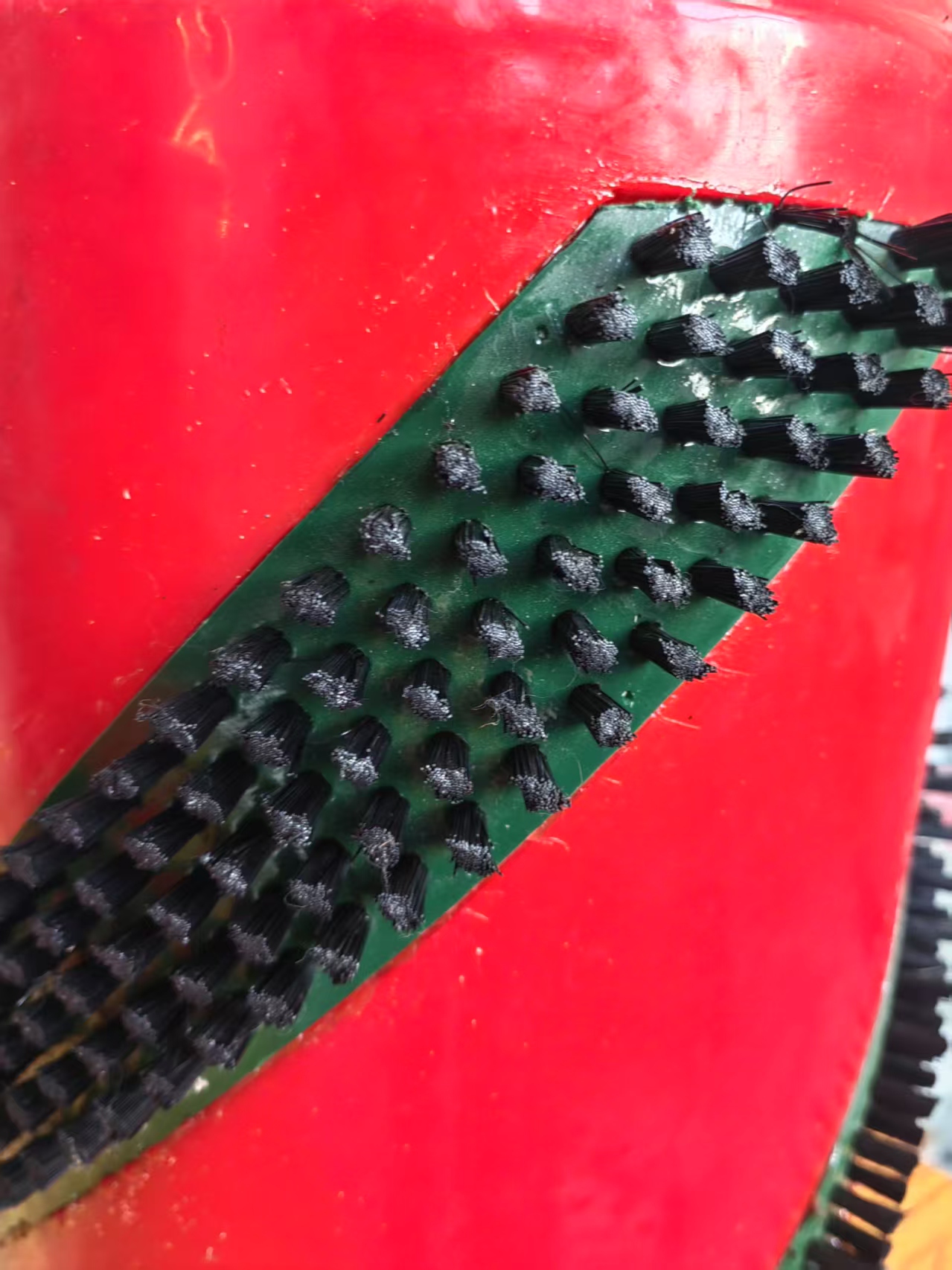

One of the standout features of the EMT Brush Pig is its magnetic brush technology. These magnetic brushes effectively collect ferrous debris from pipelines during operation. This feature is especially valuable in the oil and gas industry, where such contaminants can disrupt material flow and quality. With this design, this pig ensures cleaner pipelines and improved operational efficiency.

EMT offers the pig in customizable sizes ranging from 2 inches to 60 inches. This flexibility allows clients to select the right size for their specific pipeline diameters. Additionally, the brush pig includes cup discs and a seal disc to enhance its performance. The cup disc maintains alignment and ensures proper scrubbing of pipeline walls. Meanwhile, the seal disc drives the pig forward, enabling efficient cleaning operations. These features make the EMT Brush Pig a versatile and reliable tool for pipeline maintenance.

Parameters

| Name | Customized Foam Pig | ||||||||||

| Material | Polyurethane | ||||||||||

| Light Density | 0.02-0.3g/m3 | ||||||||||

| Medium Density | 0.08-0.12g/m3 | ||||||||||

| Heavy Density | 0.13-0.16g/m3 | ||||||||||

| Features | 1. High wear resistance | ||||||||||

| 2. Good cleaning performance | |||||||||||

| 3. Low cost | |||||||||||

| Payment | TT/LC | ||||||||||

| Advantages | 1. They are lightweight and flexible. | ||||||||||

| 2. Nice cleaning efficiency. | |||||||||||

| 3. Accurate location tracking. | |||||||||||

Choosing EMT’s Brush Pig

When deciding whether EMT’s Brush Pig is the right choice for your pipeline maintenance, consider the following:

Nature of the Contaminants: If the pipeline suffers from hard, adherent deposits, the mechanical cleaning action of the pig is ideal.

Pipeline Material and Condition: Ensure that the brush materials are compatible with the pipeline material to avoid any potential damage.

Maintenance Frequency: For pipelines that require frequent cleaning due to rapid deposit buildup, the durability and effectiveness of the Brush Pig can provide a reliable cleaning solution.

EMT’s Brush Pig is a practical choice for operators looking for an efficient, durable, and versatile cleaning tool that can adapt to various pipeline conditions and maintenance requirements. By choosing this pig, you ensure thorough cleaning and maintenance of your pipeline infrastructure, ultimately enhancing system performance and longevity.

Features and Benefits

Brush pigs are essential tools for maintaining pipeline cleanliness and efficiency. They feature stiff brushes that scrub away deposits. These deposits include wax, scale, and other residues. The brushes can adapt to various pipeline materials. They come in different stiffness levels to match specific needs.

Manufacturers design brush pigs for optimal contact with pipeline walls. This design ensures thorough cleaning across the entire pipeline circumference. Operators can customize brush sizes to fit different diameters. This customization enhances the cleaning effectiveness for diverse pipelines. The brushes often consist of durable materials like nylon or steel wire. These materials withstand harsh conditions inside pipelines.

The robust construction of brush pigs allows for repeated use. This durability reduces the need for frequent replacements. Thus, it cuts long-term maintenance costs. Brush pigs can also handle high pressures and extreme temperatures, which adds to their versatility.

Moreover, brush pigs support various pipeline applications. These include cleaning, de-watering, and gauging. This versatility makes them valuable across multiple industries. They are particularly useful in oil, gas, and water pipelines.

Ease of deployment and recovery marks another key feature. This ease minimizes maintenance downtime. Brush pigs can navigate bends and valves in pipelines. This capability minimizes the risk of jams or damage. Their ability to adapt to pipeline features ensures efficient operation.

In conclusion, brush pigs offer a reliable solution for pipeline maintenance. They provide effective cleaning, are customizable, and durable. Their versatility and operational efficiency make them a top choice for industry professionals. By choosing brush pigs, operators ensure comprehensive maintenance and extend the lifespan of their pipeline systems.