Description

Introduction

A Rapid Open Closure is a mechanical device installed at the opening of a pipeline or pressure vessel, designed for fast and efficient opening and closing. Operators commonly use bayonet-type quick opening closures for pipelines ranging from DN100 to DN350 because they are simple to operate and easy to use. For larger pipelines, from DN400 to DN1200, they recommend lock-ring type closures, as these require less force to operate and make opening and closing procedures easier.

Different Types of Rapid Open Closures

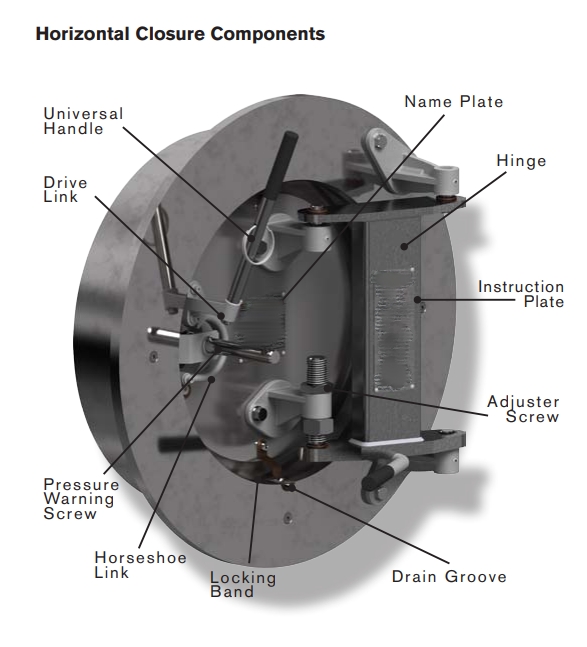

Bayonet Type Quick Opening Closure (Horizontal)

The horizontal bayonet type quick opening closure is designed for pipelines or pressure vessels that are oriented horizontally. This closure utilizes a bayonet locking mechanism, which allows for fast and secure opening and closing through a simple twisting motion. It is ideal for smaller to medium-sized pipelines (typically DN100–DN350), offering ease of access and maintenance.

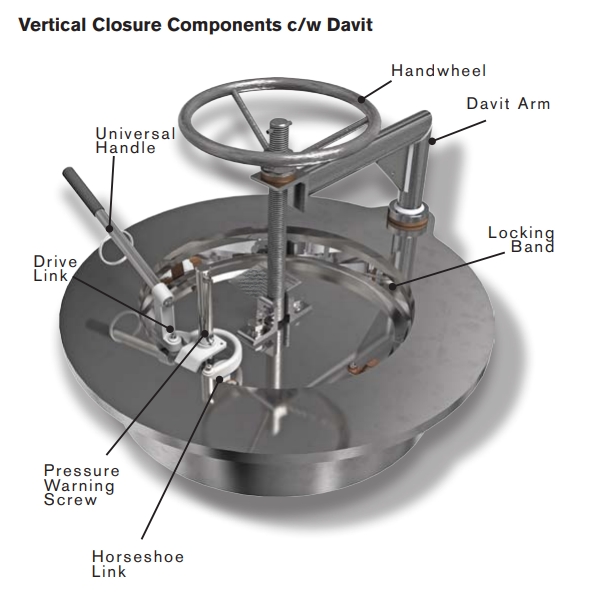

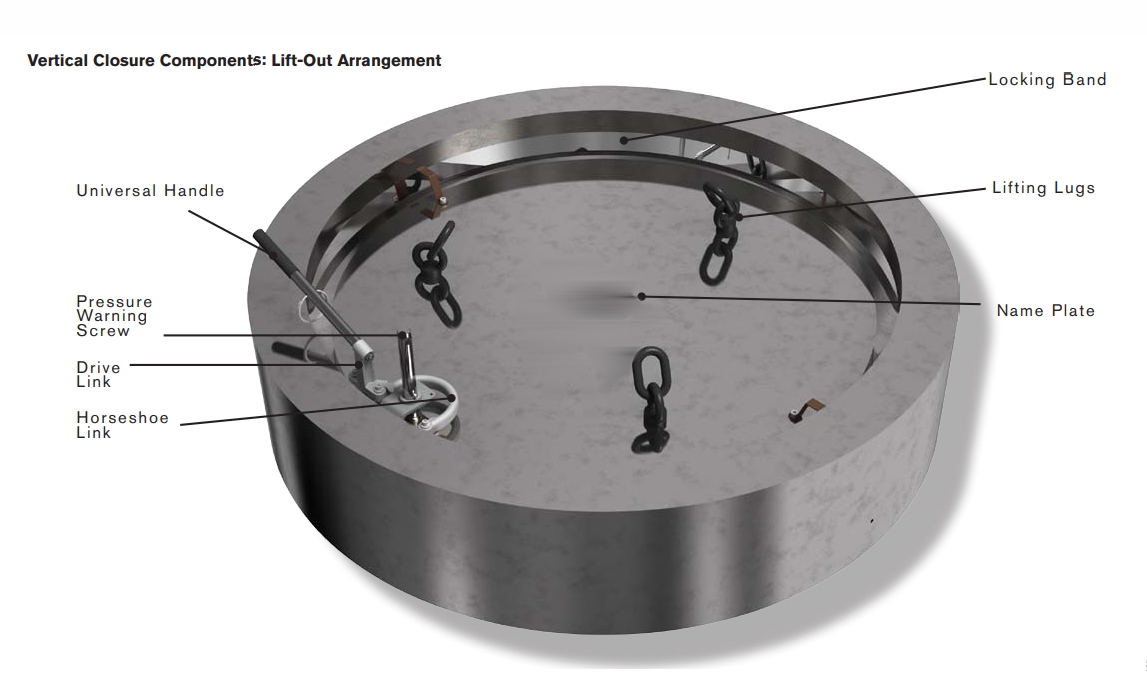

Bayonet Type Quick Opening Closure (Vertical)

The vertical bayonet type quick opening closure performs a similar function to its horizontal counterpart, but manufacturers configure it specifically for vertical pipeline systems or vessels. Operators often use it where top access is required, such as in tanks or vertical vessels. The bayonet mechanism allows for quick engagement and disengagement with minimal effort. This type is particularly advantageous in limited horizontal spaces, providing a compact and easy-to-operate solution for frequent access.

Clamp Type Quick Opening Closure (Horizontal)

The horizontal clamp type quick opening closure features a clamping mechanism that securely locks the cover in place. This design is especially suitable for medium to large pipeline systems. The horizontal orientation allows for side access, making it convenient for operators to perform inspections or maintenance. The clamp mechanism ensures uniform pressure distribution across the sealing surface, enhancing safety and leak prevention in high-pressure applications.

Clamp Type Quick Opening Closure (Vertical)

The vertical clamp type quick opening closure offers the same secure and reliable clamping mechanism as the horizontal version but is intended for vertically oriented systems. It is ideal for vessels or tanks that require top access. The vertical design, combined with the clamp locking system, ensures safe and efficient operation, even under high pressure. This type is widely used in industries where process safety and repeated access are critical.

Lock Ring Quick Opening Closure (Horizontal)

The horizontal lock ring quick opening closure suits larger pipelines (typically DN400–DN1200), and engineers design it specifically for such applications. It utilizes a lock ring mechanism to secure the closure firmly. As a result, this design reduces the operational force required, making it easier for operators to open and close, even at larger sizes. Furthermore, the horizontal orientation offers convenient side access, which simplifies entry into pipelines or vessels for inspection and maintenance. Moreover, the lock ring system delivers a strong and reliable seal, making it ideal for high-pressure and high-temperature environments.

Lock Ring Quick Opening Closure (Vertical)

The vertical lock ring quick opening closure is engineered for large vertical vessels or pipelines. It combines the advantages of the lock ring mechanism with a vertically oriented design, making it ideal for top-mounted access points. This closure type is famous for its safety, ease of use, and strong sealing capability. It is especially beneficial in applications that require frequent opening and closing without compromising safety or sealing integrity.

Technical indicators of Rapid Open Closure

Nominal Diameter DN: ≤ 1800mm

Design Temperature: -50℃ ~300℃

Design pressure PN: ≤ 40 MPa

Material: 16Mn, A350LF2, A105, SS304, SS316, F51, F53, F55, INCONEL625, HASTELLOY C

Working Medium: oil, gas, water

Pipe Thickness: 6mm~100mm