Description

Introduction to Pig Signalling

What is Pig Signalling?

At its core, pig signalling is the method used to detect and confirm that a pig has passed a specific point in a pipeline. Think of it as a tracking system for a tool that travels in the dark, under pressure, and often over long distances.

A pig signaler (or pig detector) is a mechanical or electronic device installed on a pipeline at a predetermined location, such as a launcher or receiver station. When the pig passes by, it triggers the device, sending a clear signal—often an audible alarm, a visual indicator on a control panel, or a data log entry.

This simple “yes” or “no” confirmation is deceptively powerful. It provides operators with the certainty needed to proceed with the next steps of a complex operation.

Why is Pig Signalling So Critical?

The importance of reliable pig signalling cannot be overstated. It is the linchpin of safety and operational control for several key pipeline activities:

Launch and Receive Confirmation: The most basic function. Operators must know definitively that the pig has fully exited the launcher and has been successfully received in the trap. A failed signal can indicate a stuck pig, leading to major operational disruptions.

In-Line Inspection (ILI) Tool Tracking: When running “smart pigs” that carry sensitive and expensive sensors to map pipeline geometry, detect metal loss, or find cracks, knowing their exact location is crucial. Pig signalling provides vital checkpoints to correlate the tool’s internal data with its physical location.

Pipeline Integrity and Safety: By confirming a pig’s passage, operators can verify that internal obstacles (dents, debris) have been cleared and that the pipeline’s internal diameter is within tolerance. This directly prevents failures and ensures the safe transport of oil, gas, and other products.

How Does Pig Signalling Work?

Pig signalling systems rely on detecting the physical presence of the pig. The two most common types of signalers are:

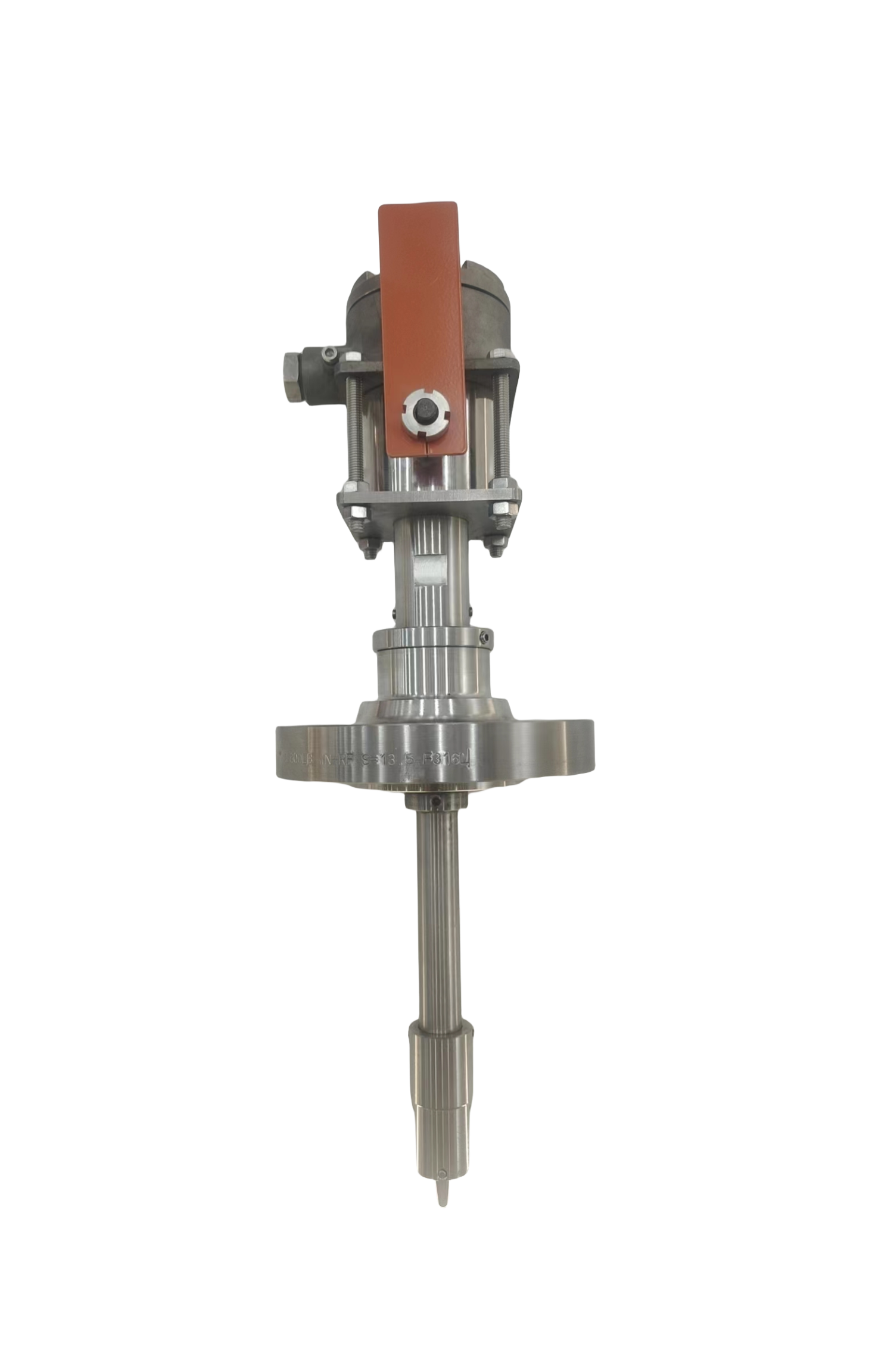

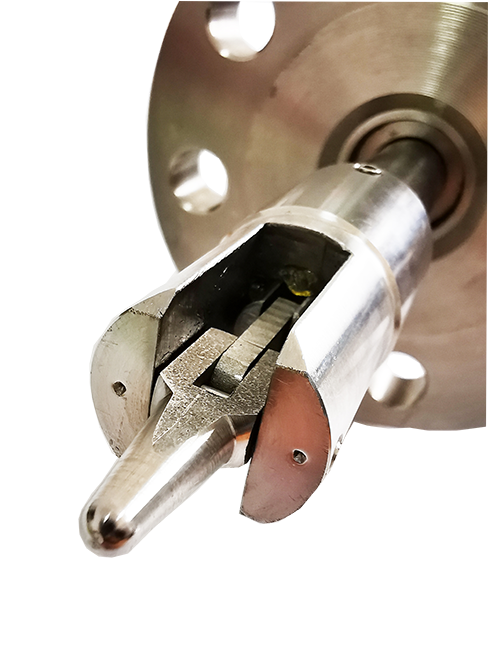

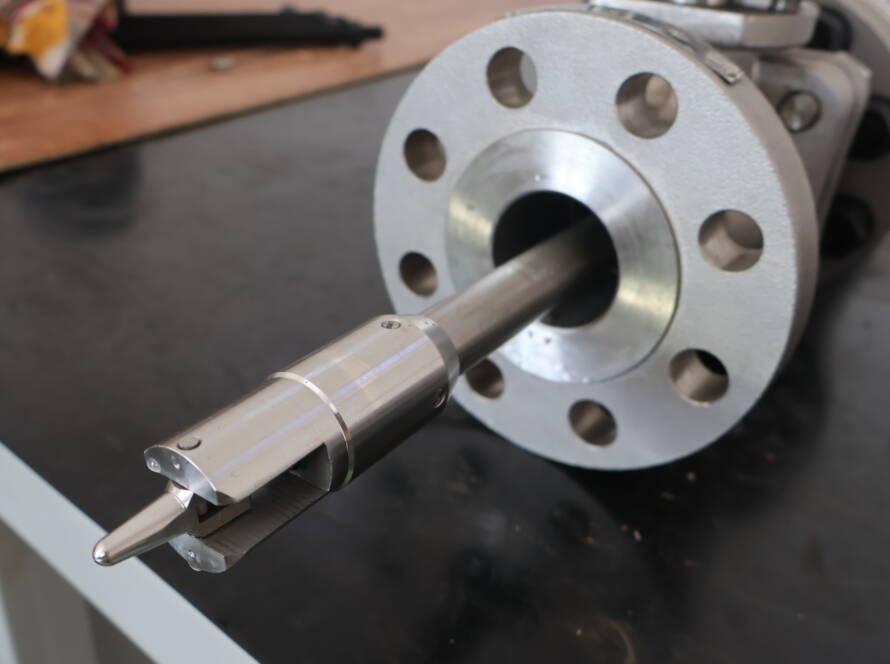

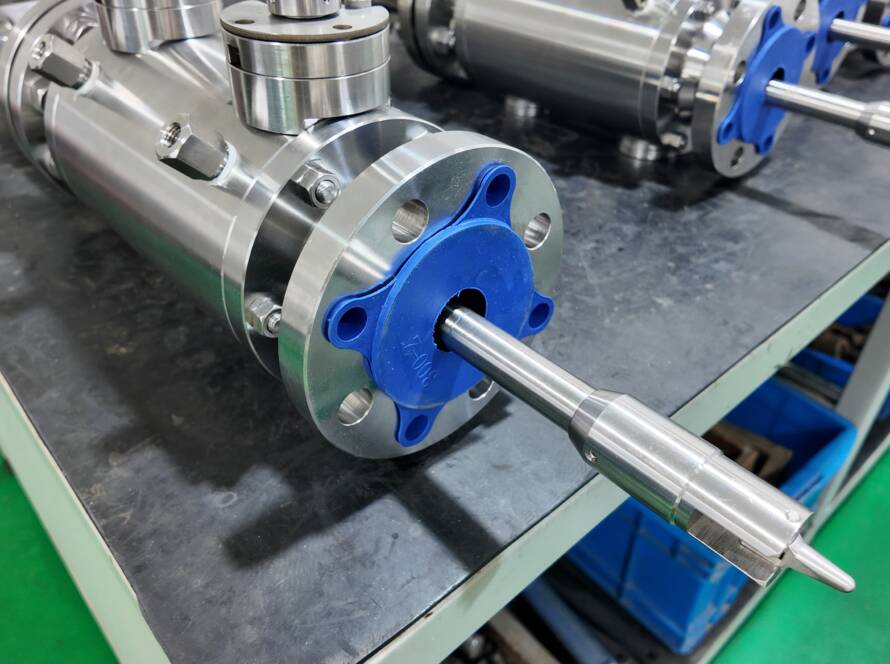

1. Mechanical Pig Signallers

These are the workhorses of the industry, prized for their simplicity and reliability. A mechanical signaller consists of a trigger or finger that protrudes into the pipe. When the pig passes, it physically deflects this trigger. This mechanical action is transferred to a visual indicator on the outside of the pipe—typically a brightly colored flag or pointer that pops up or rotates.

Advantages: Intrinsically safe (no electrical power needed), highly reliable, easy to install and interpret visually.

Disadvantages: Provides only a local visual indication, requires personnel to be on-site to see it.

2. Electronic Pig Signallers

For remote monitoring and data integration, electronic signalers are the preferred choice. These systems use sensors to detect the pig and then transmit an electronic signal to a control room.

Advantages:

- Most importantly, these systems allow for remote, real-time monitoring.

- Moreover, they can be integrated with SCADA systems.

- In addition, they provide valuable data for historical records and analysis.

Disadvantages:

- However, they tend to be more complex.

- Furthermore, they require a power source.

- Consequently, they can be more expensive than simpler alternatives.

Best Practices for Effective Pig Signalling

To ensure a successful pigging operation, the pig signalling process must be flawless:

Proper Installation: Signalers must be installed correctly according to manufacturer specs and pipeline pressure codes.

Routine Testing: Before launching a pig, the signalling device should be tested to ensure it is functioning correctly.

Clear Communication: All personnel involved must understand what the signal means and what the subsequent actions are.

Redundancy: On critical runs, using two independent pig signalling devices provides a backup and eliminates uncertainty.

Conclusion: More Than Just a Signal

Pig signalling is far more than a simple technical step; it is a fundamental practice in pipeline integrity management. It is the critical link that provides certainty in an uncertain environment, ensuring the safety of personnel, the protection of the environment, and the reliability of the energy infrastructure we all depend on.

By investing in reliable pig signalling technology and adhering to strict procedures, pipeline operators can mitigate risk, optimize maintenance, and extend the safe life of their assets.

Parameters

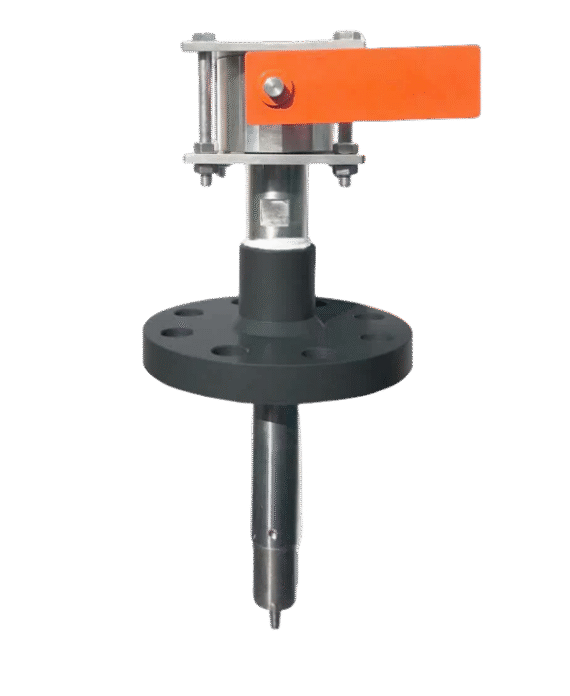

| Name | 20mm Adjustable Pig Indicator |

| Connection | Flange Connection |

| Plug body length | 200mm |

| Operating temperature | —20~120℃/Meet customer requirements |

| NACE MR 01- 75 | Yes |

| Ingress protection | IP65/IP66 |

| Explosion-proof class | ExdⅡ BT4 |

| Remove under pressure | No |

| Trigger type | Bi-directional/Uni-directional |

| Adjustable length | 20mm |

| Internal part material | 316SS/DSS/INCONEL |

| Insert depth | 21mm(Bi)/13mm(Uni) |

| Flange/Body material | PTFE coated A105N/304SS/316SS/DSS/INCONEL(As per MR) |