Description

What Is a Bidirectional Pig Signaller and Why You Need One

A Bidirectional Pig Signaller is a crucial device in pipeline operations. It detects the movement of pigs in both directions. Operators install it to monitor flow assurance and pigging operations in real-time.

Unlike traditional models, the Bidirectional Pig Signaller works with forward and reverse pig movement. It improves safety, reduces downtime, and ensures efficient pipeline maintenance. For industries that operate critical pipelines, this tool makes all the difference.

How a Bidirectional Pig Signaller Works

The Bidirectional Pig Signaller uses mechanical or electronic sensors. These sensors detect the passage of a pig in either direction. Once a pig passes, the signaller sends visual or audible signals instantly.

Because of this immediate feedback, operators can act without delay. They can adjust flow, stop pumps, or initiate cleaning. Also, the Bidirectional Pig Signaller helps avoid pig loss or pipeline blockages.

Many models offer a manual reset feature. After a pig passes, the operator resets the device for the next signal. Some models include digital outputs for SCADA integration. Therefore, operations teams stay informed 24/7.

Features

A reliable Bidirectional Pig Signaller includes corrosion-resistant housing. It also withstands high pressure and extreme temperatures. These features make it ideal for oil, gas, water, and chemical pipelines.

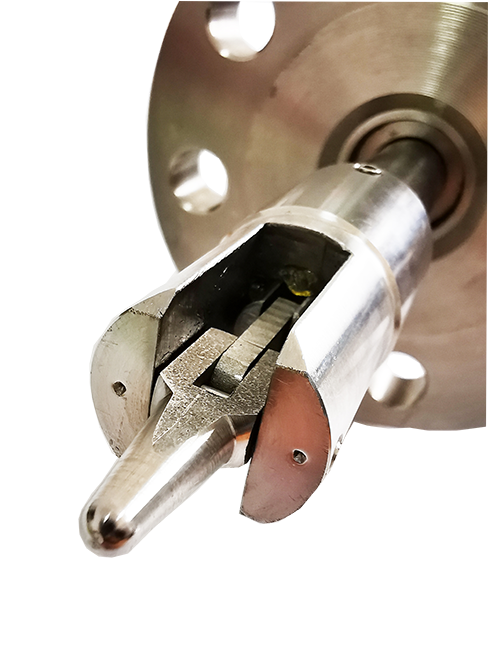

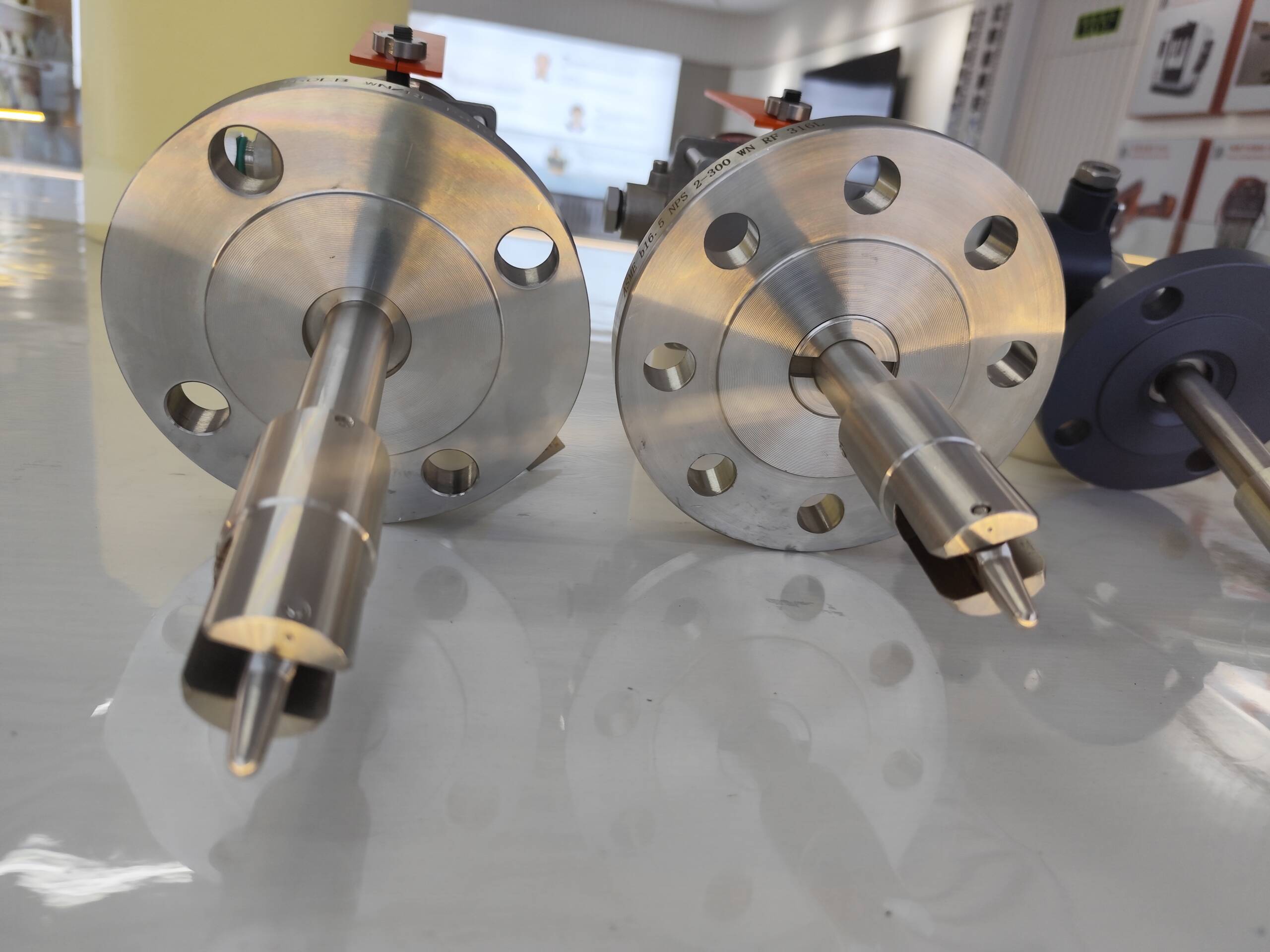

Most units offer either intrusive or non-intrusive installation methods. Intrusive types use a plunger mechanism. Non-intrusive types use magnetic or acoustic sensors. Both types serve different needs, depending on the pipeline design.

In addition, a premium Bidirectional Pig Signaller includes explosion-proof certification. This is essential for hazardous or flammable environments. Engineers can trust its safety and performance under tough conditions.

Benefits of Bidirectional Pig Signaller

Using a Bidirectional Pig Signaller provides many benefits. First, it improves pipeline safety. Second, it ensures accurate pig tracking in both directions. Third, it minimizes downtime and maintenance costs.

Moreover, the Bidirectional Pig Signaller reduces human error. Operators receive real-time confirmation of pig passages. As a result, there’s no guessing or second-guessing. Every movement is confirmed.

It also increases productivity. Teams can plan maintenance and cleaning without delays. Besides that, it supports automated monitoring systems. This makes it ideal for modern pipeline networks.

Industries That Use It

Many industries use the Bidirectional Pig Signaller every day. Oil and gas companies use it for routine pigging. Chemical plants use it to prevent contamination. Water utilities use it for pipeline cleaning and inspection.

Even in mining and offshore drilling, the Bidirectional Pig Signaller plays a key role. Its rugged design and dual-direction sensing make it irreplaceable.

Choosing the Right One

Before making a purchase, it’s essential to evaluate key factors such as pressure ratings, sensor technology, and specific installation requirements. The chosen device should align closely with the specifications of your pipeline system to ensure accurate performance and long-term reliability. Additionally, always make sure that the device is compliant with regional safety regulations and industry standards.

Partnering with reputable manufacturers or suppliers is also a critical step. These providers typically offer valuable services like technical support, user training, and availability of replacement parts. Such support ensures that your equipment operates efficiently and remains in top condition for many years, reducing the likelihood of costly downtime or maintenance issues.

Conclusion

To sum up, this monitoring tool plays a vital role in today’s pipeline infrastructure. By tracking internal operations in both directions, it enhances operational safety, reduces unnecessary expenses, and boosts overall efficiency.

For anyone responsible for managing pipeline systems, incorporating this technology is a smart and forward-thinking decision. Selecting a durable, high-quality solution from a trusted source empowers your operations with better visibility, greater control, and long-term peace of mind. Investing in the right equipment today can lead to smoother processes, fewer disruptions, and improved productivity tomorrow.