Description

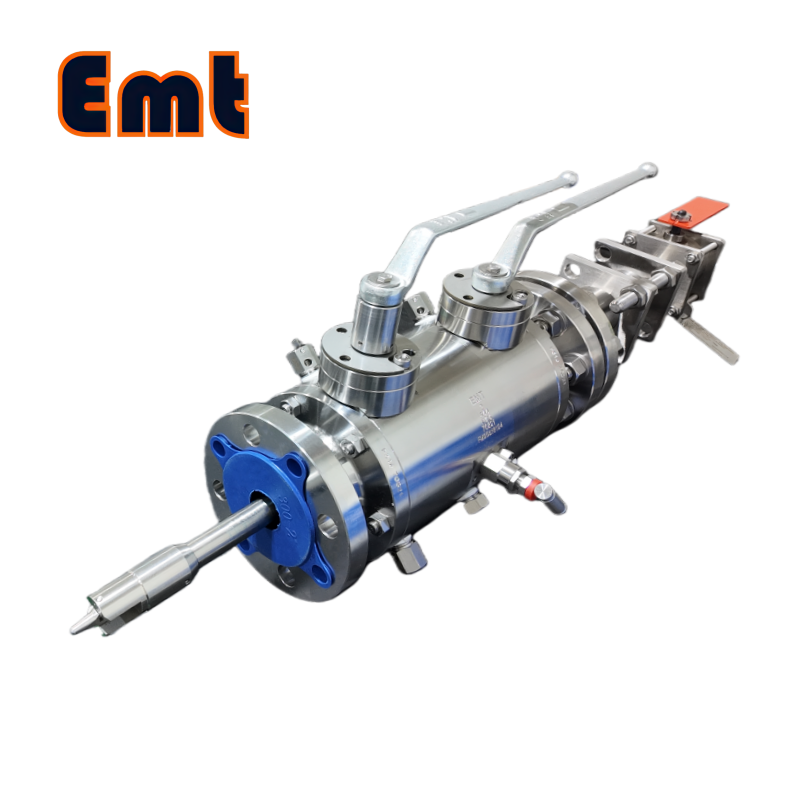

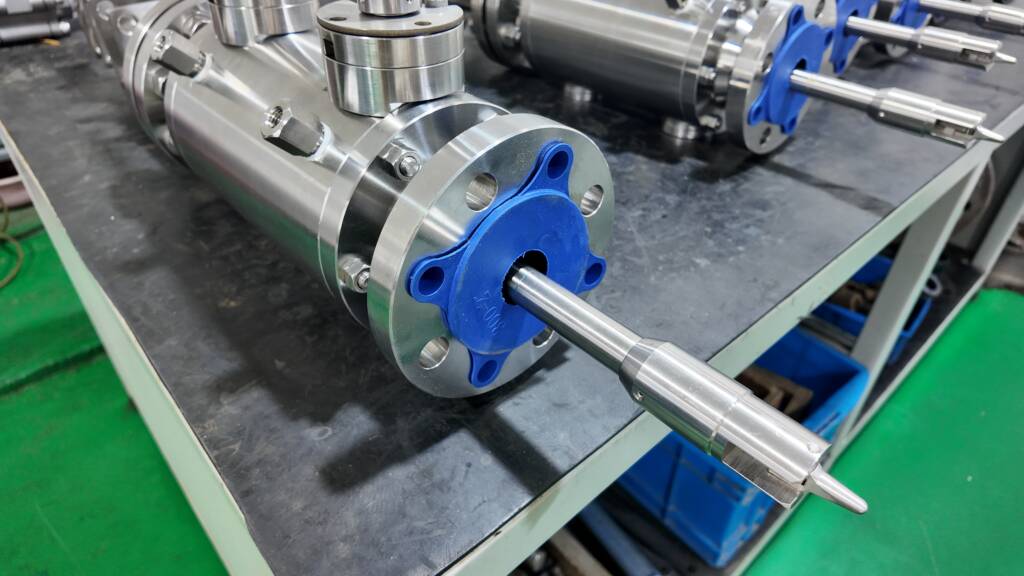

Pig passage indicators serve as essential monitoring devices in pipeline systems, providing accurate confirmation of pig movement during cleaning, inspection, and maintenance operations. These robust indicators deliver real-time information about pig location, enabling operators to maintain operational control and ensure the efficiency of pipeline management programs.

1. Technical Specifications

Material Construction

-

Stainless Steel 304: General corrosion resistance for standard applications

-

Stainless Steel 316: Enhanced corrosion resistance for marine and chemical environments

-

DSS F51: High strength with excellent corrosion resistance

-

Carbon Steel A105N: Robust performance in high-pressure systems

-

Inconel 625: Superior resistance to extreme temperatures and corrosive media

Pressure Ratings

Comprehensive pressure class options from 150# to 2500#, ensuring compatibility with various pipeline pressure requirements across different industries and applications.

Temperature Range

Operational capability from -20°C to +120°C, maintaining reliable performance across diverse environmental conditions and seasonal variations.

2. Key Features of Pig Passage Indicators

Operational Reliability

-

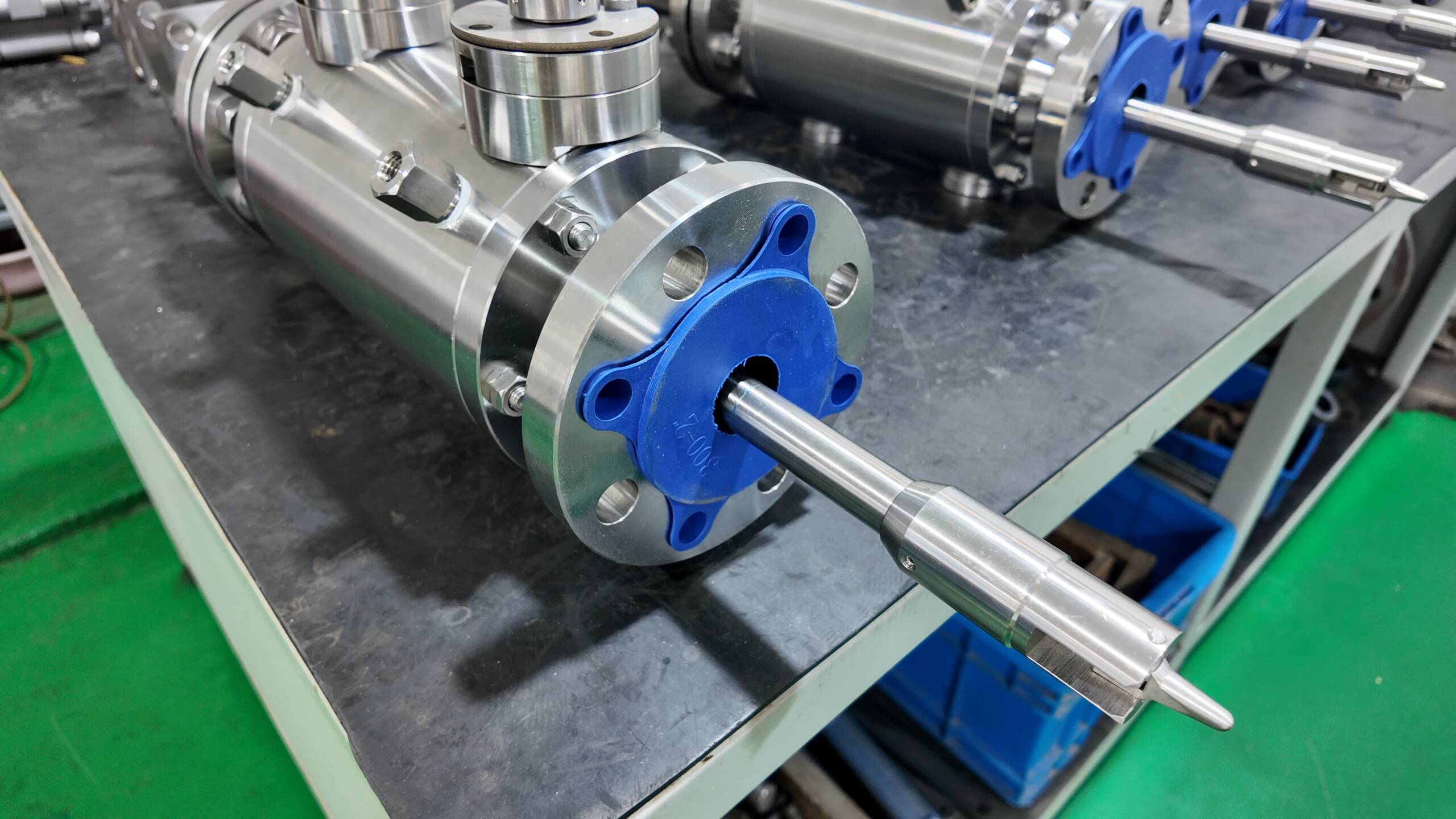

Direct intrusive detection method provides positive pig passage confirmation

-

Robust construction ensures long-term performance in demanding environments

-

Multiple material options accommodate various pipeline media and conditions

-

Wide pressure and temperature ratings suit diverse operational requirements

Installation Flexibility

-

2″ flange connection for standard pipeline integration

-

2″ welded nipple for permanent installation solutions

-

2″ welded base with NPT nipple connection for versatile mounting options

-

Adaptable to both new installations and existing pipeline systems

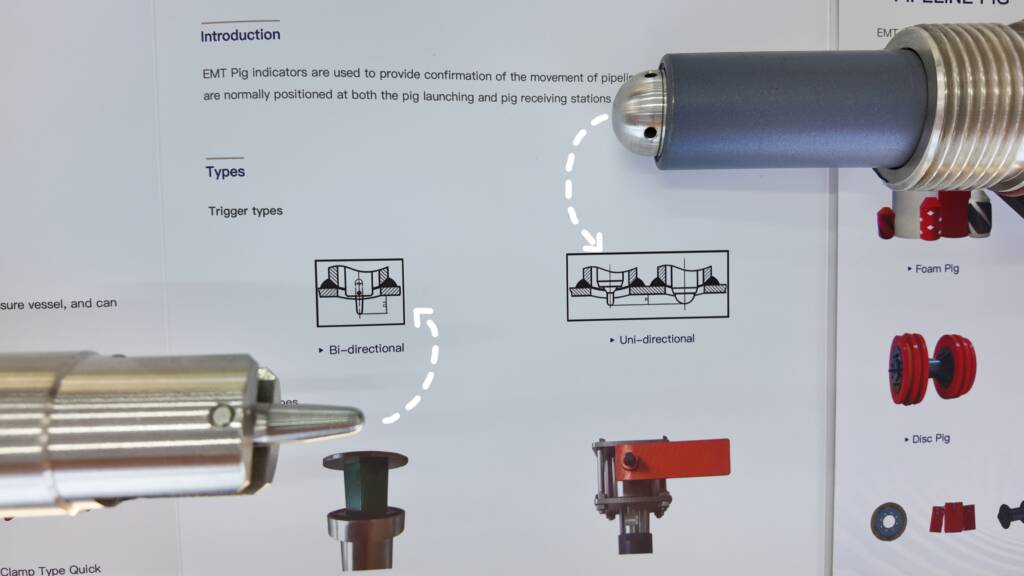

Detection Versatility

-

Bi-directional triggers for pipelines with reversible flow

Bi-directional triggers for pipelines with reversible flow -

Bi-directional feather triggers for enhanced sensitivity

-

Uni-directional triggers for single-direction pipeline systems

-

Multiple indicator types to match operational preferences

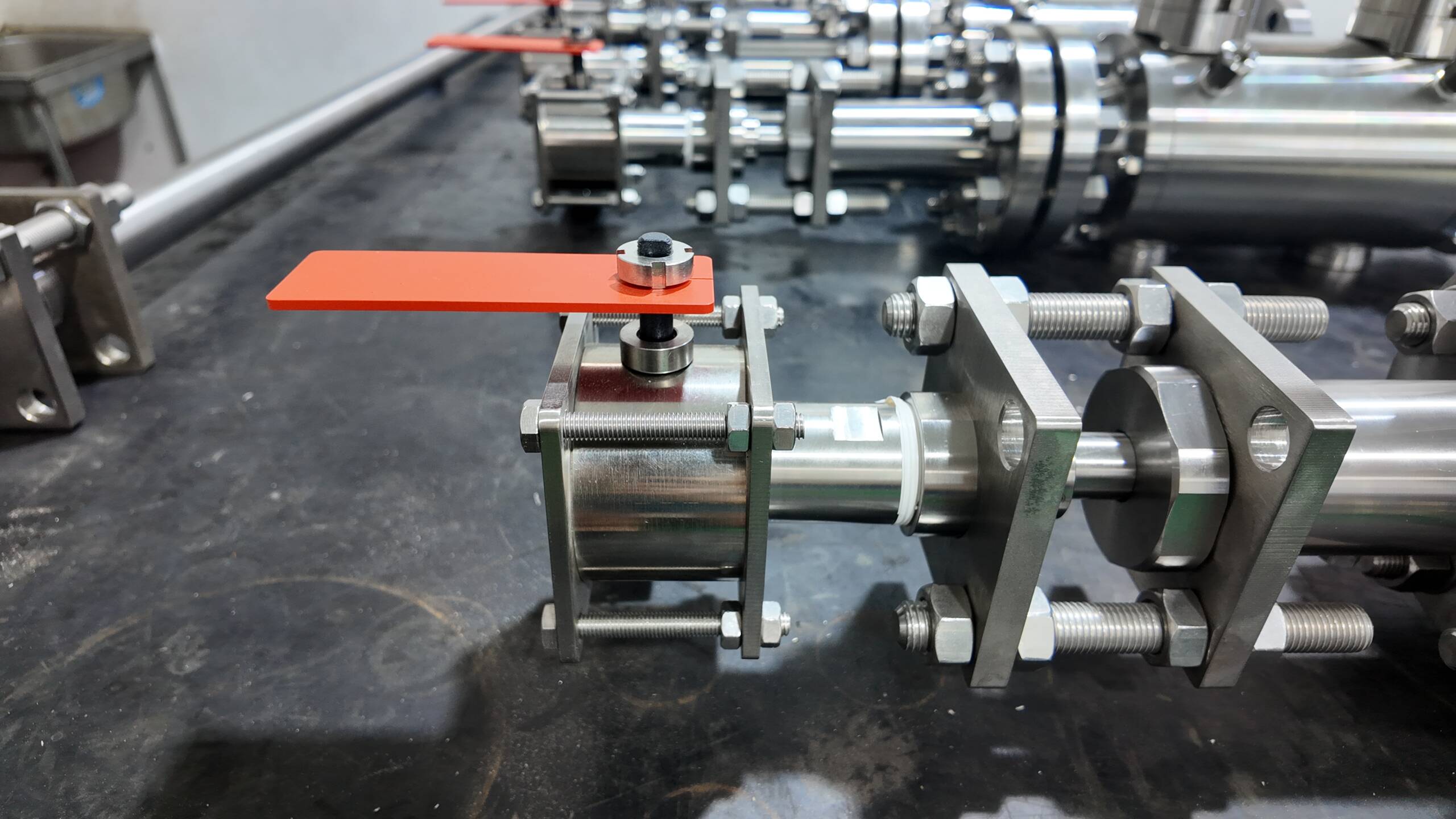

Indicator Options

-

Manual reset flag for basic visual confirmation

-

Manual reset flag with electrical switch output for system integration

-

Digital display with electrical switch output for advanced monitoring

3. Selection Guidance

Trigger Type Selection

-

Bi-directional: Suitable for pipelines with flow reversal capability

-

Bi-directional feather: Recommended for detecting low-profile or lightweight pigs

-

Uni-directional: Appropriate for systems with consistent flow direction

Indicator Type Considerations

-

Manual flags: Basic applications where visual monitoring is sufficient

-

Electrical switch output: Systems requiring remote monitoring or alarm integration

-

Digital displays: Applications needing detailed operational data and remote access