Description

EMT Non Intrusive Pig Signaller represents a significant technological advancement in pipeline monitoring systems, designed to track pig passage without any physical penetration of the pipeline. This sophisticated detection system eliminates the need for pipeline modifications while providing reliable, real-time monitoring of pig movement through magnetic sensing technology. Particularly valuable for hazardous environments and critical pipeline operations, this solution maintains complete pipeline integrity while delivering accurate passage detection data.

1. Key Operational Advantages

Zero Pipeline Penetration

The non-intrusive design eliminates potential leak points and maintains pipeline structural integrity. This approach prevents the operational risks associated with traditional intrusive detectors while enabling continuous pipeline operation during monitoring activities.

Enhanced Safety Compliance

With ExdIICT6Gb explosion-proof certification and IP65 environmental protection, the system operates safely in hazardous areas and challenging environmental conditions. This ensures personnel safety and equipment protection in volatile operating environments.

Precise Data Acquisition

The system delivers accurate passage timing and reliable event logging, supporting effective maintenance scheduling and pipeline integrity management. The 99-event storage capacity provides substantial historical data for trend analysis and performance monitoring.

Reduced Operational Impact

Installation and maintenance activities can be performed without pipeline shutdown or depressurization. This capability significantly reduces downtime costs and maintains continuous product flow during detector installation and service.

2. Application Scenarios

Hazardous Environment Operations

Ideal for oil and gas pipelines transporting volatile substances where safety and containment are paramount concerns.

Buried Pipeline Systems

Effective for monitoring pig passage in submerged or buried pipelines where physical access is limited or impractical.

Insulated Pipeline Networks

Suitable for applications requiring maintained thermal insulation while ensuring reliable pig tracking capabilities.

High-Throughput Operations

Perfect for continuous operation pipelines where shutdowns for detector maintenance are economically prohibitive.

3. Core System Components

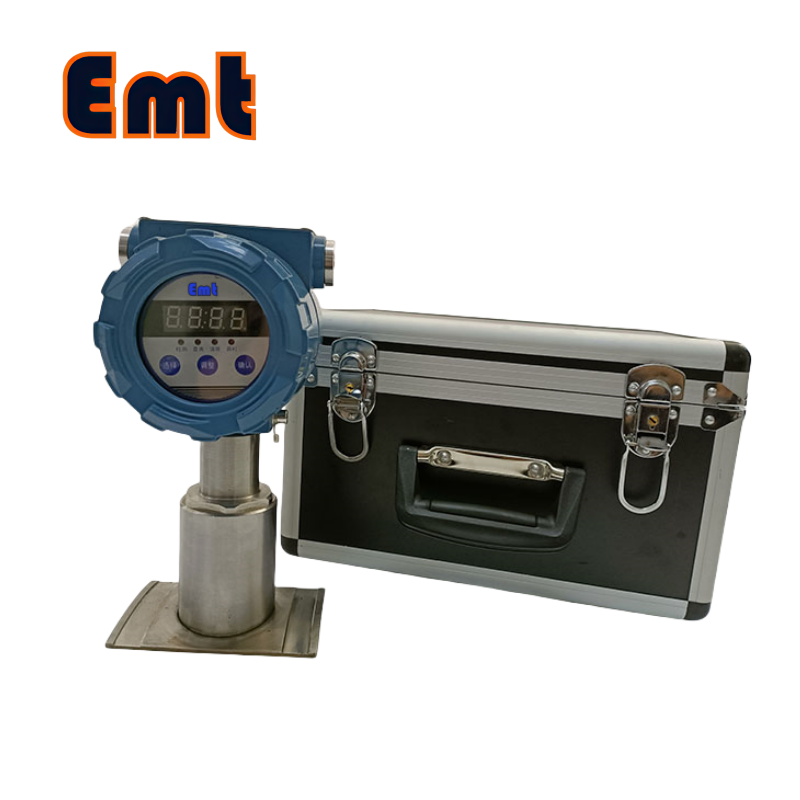

Explosion-Proof Remote Display Unit (TZS)

The system’s central processing unit features robust explosion-proof construction certified to ExdIICT6Gb standards with IP65 protection rating. The display unit incorporates an LCD with heating capability for reliable operation across diverse environmental conditions. With capacity to store up to 99 passage events, the TZS unit provides comprehensive data logging while enabling remote data transmission for centralized monitoring.

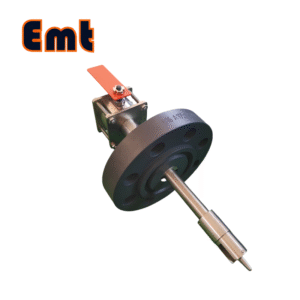

High-Sensitivity Sensor Mechanism (YY-FCT)

Engineered for precise magnetic field detection, the YY-FCT sensor mounts externally on the pipeline wall to detect magnets embedded in passing pigs. This component delivers exceptional sensitivity for accurate passage detection while maintaining complete non-intrusive operation.

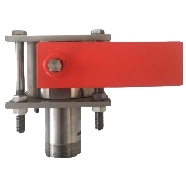

Adaptable Mounting System

The card mounting mechanism offers flexible installation options with specialized clamps designed to accommodate various pipeline specifications. This modular approach ensures secure attachment regardless of pipeline diameter or configuration.

Extended Connectivity Solutions

Connection wires and extension rods provide flexible installation options, particularly valuable for buried pipelines or hard-to-access locations. The system accommodates pipeline insulation requirements through proper sensor placement directly on the metal pipe wall prior to insulation application.

4. Operating Principle of Non Intrusive Pig Signaller

Magnetic Field Detection

The system operates through advanced magnetic sensing technology. As pigs equipped with permanent magnets pass through the pipeline, they generate distinct magnetic fields that are detected by the externally-mounted sensors.

Signal Processing & Data Management

Upon detecting Non Intrusive Pig Signaller, the sensor generates electrical signals transmitted to the TZS display unit. The system records exact passage timestamps and maintains comprehensive event logs for operational analysis and maintenance planning.

Remote Monitoring Capabilities

The system enables real-time remote monitoring through switch signal transmission to central control centers. This allows operators to track pig progress throughout the pipeline network without physical presence at detection points.