Description

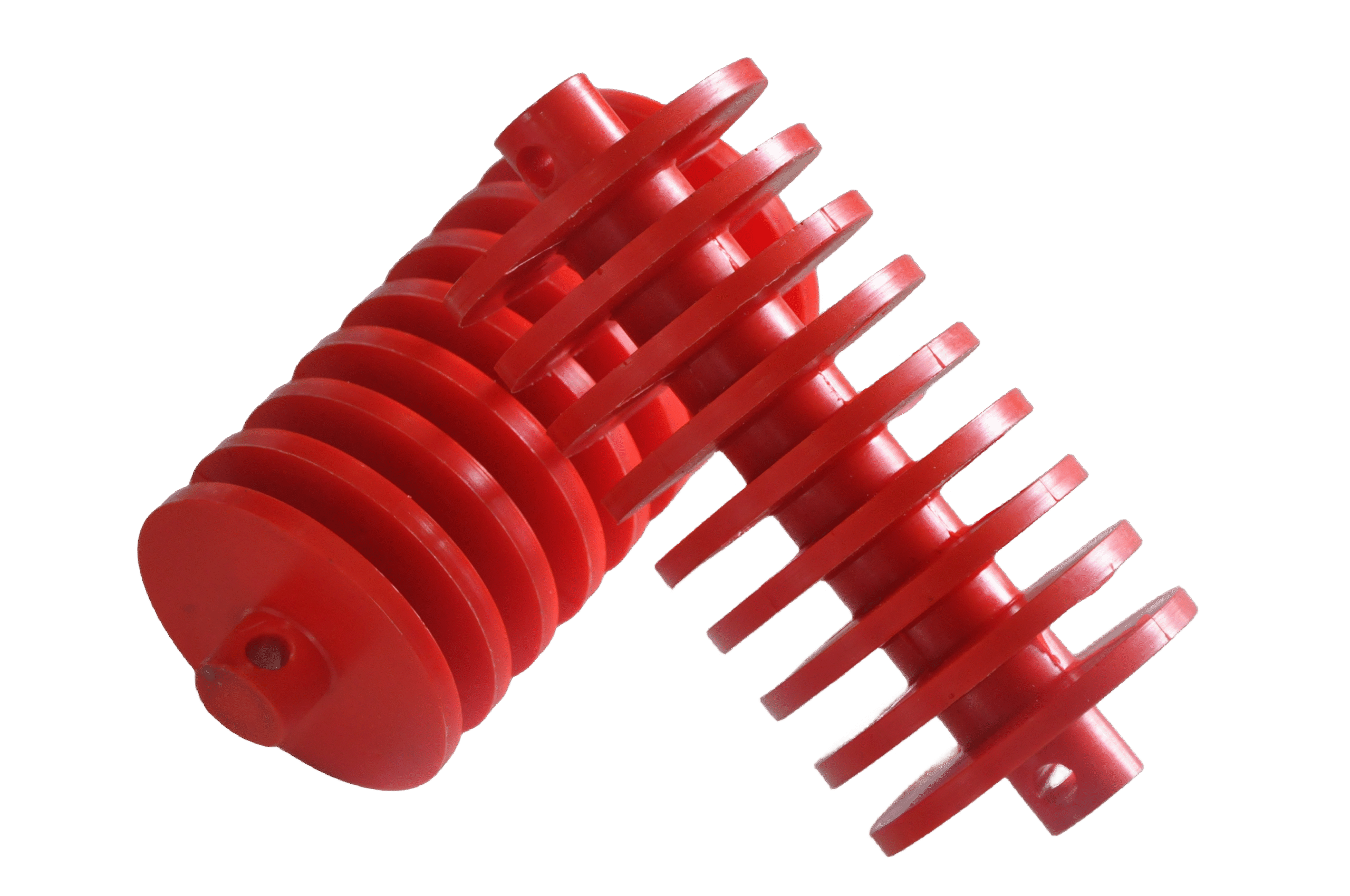

EMT introduces the Polyurethane Solid Cast Pipeline Cleaning Cup Pig, a robust and efficient solution tailored for the energy and mining industries. This product embodies EMT’s commitment to delivering high-performance cleaning tools that meet the rigorous demands of pipeline maintenance.

Key Features and Specifications of EMT’s Solid Cast Pig

EMT’s Solid Cast Cup Pig is a cutting-edge tool designed for the rigorous demands of pipeline maintenance, particularly in the energy and mining sectors. This pig combines durability, adaptability, and high performance to ensure effective pipeline cleaning under a variety of operational conditions. Here’s a closer examination of its key features and specifications:

1.Material Quality

Constructed from high-grade polyurethane, the Solid Cast Cup Pig stands out for its exceptional durability and resilience. And then polyurethane is favored for its resistance to wear, abrasion, and various chemical exposures, making it ideal for traversing rough pipeline environments. This material ensures that the pig can withstand repeated use without significant degradation, thereby extending its service life and enhancing return on investment.

2.Color Options

Available in vibrant red or yellow, these color options are not just about aesthetics; they serve a practical purpose. Enhanced visibility is crucial for operational safety and ease of inspection. And then ,after a cleaning operation, workers can easily spot the pig, assess its condition, and ensure no parts are left behind in the pipeline, which could obstruct the flow or damage the infrastructure.

3.Size Range

With a size range from 2 inches to 40 inches, the Solid Cast Cup Pig is extremely versatile and can woek in a wide array of pipeline diameters. This versatility ensures that EMT’s customers can select a size that fits their specific pipeline perfectly, optimizing the cleaning process and ensuring that the pig can navigate the pipeline effectively, regardless of its diameter.

4.Weight and Performance

Weighing 4 KG, this pig is robust enough to handle intensive cleaning tasks while still being light enough to maintain excellent maneuverability within the pipeline. This balance is crucial for ensuring that the pig can effectively remove debris and buildup without causing damage to the pipeline or becoming lodged in narrower sections.

5.Working Temperature

The Solid Cast Cup Pig operates effectively up to 80°C, making it suitable for use in environments where high temperatures are common. This feature is particularly important for industries such as oil and gas, where the internal pipeline temperatures can vary significantly.

6.Hardness

With a hardness of Shore 83 A, the pig has good design to maintain its structural integrity under pressure and against rough internal surfaces of pipelines. Also,this level of hardness is ideal for dealing with tough scale and other residues that softer materials might not be able to handle effectively.

7.Minimum Order Quantity (MOQ)

Offering a MOQ of just one piece allows customers to order according to their immediate needs, without the requirement for bulk purchasing. This flexibility is particularly beneficial for smaller operations or for those requiring a specific pig for a trial or a one-off cleaning operation.

8.Usage

Primarily designed for thorough cleaning, the Solid Cast Cup Pig is effective at removing various types of debris and buildup from pipelines. And then its robust design and material choice make it an excellent tool for maintaining flow efficiency and preventing potential blockages that could lead to operational downtime or extensive maintenance.

In summary, the EMT Solid Cast Cup Pig is suitable to meet the high standards required in modern pipeline maintenance, offering a combination of durability, operational flexibility, and effective cleaning performance. Also,this makes it an essential tool for industries committed to maintaining the health and efficiency of their pipeline systems.

Quality Assurance and Compliance of EMT’s Solid Cast Pig

Quality Assurance and Compliance of EMT’s Solid Cast Pig

Certification: ISO 9001 certified, highlighting adherence to international quality standards

Video Outgoing-Inspection: Each unit is suitable to a detailed visual inspection before shipment, ensuring quality and functionality

Machinery Test Report: Provided with every unit, offering a comprehensive review of product performance and specifications

Logistics and Packaging

Place of Origin: Crafted with precision in Liaoning, China

Packaging Details: Each pig is packaged individually in a box measuring 45x35x20 cm

Gross Weight per Unit: 8.000 kg, ensuring the product is protected during transit

Port of Shipment: Dispatched globally from Dalian, China, facilitating efficient logistics

Warranty and Support of EMT’s Solid Cast Pig

Warranty: Backed by a 1-year warranty, EMT guarantees reliability and support, ensuring customer satisfaction and trust.

Showroom Location: No physical showroom, focusing on direct and online client interactions to enhance service efficiency.

So, the EMT Polyurethane Solid Cast Pipeline Cleaning Cup Pig have a good design suitable to deliver exceptional cleaning performance, crucial for maintaining pipeline integrity and flow efficiency. And then its robust design and adaptable features make it an indispensable tool for operations demanding the highest standards of cleanliness and operational uptime. Ideal for a wide range of pipeline cleaning applications, this pig combines functionality with durability, ensuring long-term benefits and optimal pipeline performance.