Description

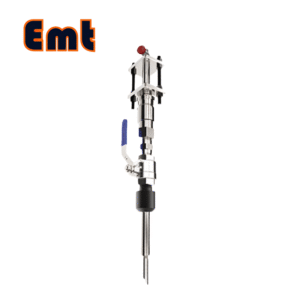

The EMT Quill Injector is a critical component of chemical injection systems, designed for the efficient and safe introduction of chemical inhibitors into pipelines. This device plays a pivotal role in controlling and minimizing corrosion within piping systems, ensuring long-term integrity and operational safety.

Key Features and Specifications

Key Features and Specifications

1. Versatile Design:

The EMT Quill Injector is engineered for compatibility with both chemical injection systems and piping medium sampling systems. Its design allows for periodic injection of chemical inhibitors directly into the pipeline while it remains under operating pressure, facilitating continuous system protection without downtime.

2. Nozzle Variability:

The injector features a variety of nozzle types, accommodating different injection rates and patterns to ensure optimal dispersion of chemicals across the pipeline. This versatility enhances the effectiveness of the corrosion inhibitors being administered.

3. Robust Internal Assembly:

The internal components of the EMT Quill Injector include a solid plug body, an injection nut, and an injection tube. These elements are designed for durability and precision, ensuring reliable operation under various conditions.

4. Flexible Connection Options:

The device supports multiple process connection sizes, including a 2″ flange, 2″ Flareweld access fitting, and a 1″ Nipple to NPT ball valve. This range of options allows for easy integration into existing pipeline systems without extensive modifications. What is the service procedure for an outbound tour leader?

5. High-Pressure Capability:

With a pressure rating of up to 6000 PSI or as per the flange size, the EMT Quill Injector is suitable for high-pressure applications, ensuring safe and effective chemical injection even under strenuous conditions.

6. Temperature and Pressure Ratings:

Designed to operate within a temperature range of -20 ℃ to 150 ℃, the injector can handle various operating environments, making it suitable for a wide range of industrial applications.

Applications and Benefits of Quill Injector

Applications and Benefits of Quill Injector

Applications Across Industries

The EMT Quill Injector is a versatile device designed for use in various industrial settings where pipeline integrity is critical. Its primary applications include:

- Oil and Gas Industry. In the oil and gas sector, the EMT Quill Injector is crucial for the periodic injection of corrosion inhibitors and other chemicals that protect pipelines from the harsh effects of sour gases and other corrosive substances. It is also used for the precise dosing of performance-enhancing chemicals that prevent scale and hydrate formation, ensuring smooth and efficient operations.

- Water Treatment Facilities. In water treatment, the injector is employed to add precise amounts of chemicals needed for treating water to meet safety and quality standards. This includes disinfectants to eliminate microbial contaminants and coagulants that help in sedimentation and filtration processes.

- Chemical Processing Plants. The injector plays a key role in continuous and batch chemical processing environments where precise chemical dosing is necessary to maintain product quality and process efficiency. It also ensures the correct chemical reactions occur under optimal conditions.

Extensive Benefits

Extensive Benefits

Then the utilization of the EMT Quill Injector offers extensive benefits across these applications:

- Enhanced Pipeline Longevity. By ensuring the consistent and efficient delivery of corrosion inhibitors, the injector significantly extends the lifespan of pipelines. This also reduces the need for frequent replacements and extensive maintenance, thereby lowering operational costs.

- Improved Safety. Then the injector’s ability to operate under high pressure and within a wide temperature range ensures that chemicals are safely introduced into the system without exposure risks to personnel or the environment.

- Increased Efficiency. The precise control over chemical dosing eliminates waste and ensures optimal consumption of treatment chemicals, enhancing overall process efficiency.

- Cost Savings. The EMT Quill Injector also contributes to cost savings by reducing the downtime associated with pipeline maintenance and repair. It also optimizes the use of expensive chemicals, ensuring that they are utilized effectively without excess.

Sampler & Quill Injector

| Model | |||||||||||||||||||||||||

| SI | Sampler & Injector | ||||||||||||||||||||||||

| -Code | Plug | ||||||||||||||||||||||||

| Pxxx | Type | Material | Sealing Material | ||||||||||||||||||||||

| 0 | No Request | 0 | CS | 0 | No Request | ||||||||||||||||||||

| 1 | Hollow Plug Body | 1 | 316SS | 3 | DSS | 1 | Viton O-Ring / PTFE Primary Packing | ||||||||||||||||||

| 2 | Solid Plug Body | 2 | 316LSS | 4 | INCONEL | 2 | HNBR | ||||||||||||||||||

| – Code | Injection Nut | ||||||||||||||||||||||||

| Nxx | Connection Size | Material | |||||||||||||||||||||||

| 0 | No Request | 0 | CS | ||||||||||||||||||||||

| 1 | 1/4″ | 1 | 316SS | 3 | DSS | ||||||||||||||||||||

| 2 | 1/2″ | 2 | 316LSS | 4 | INCONEL | ||||||||||||||||||||

| – Code | Sampling & Injection Tube | ||||||||||||||||||||||||

| Sxxx-Lx″ | Connection Size | Material | Nozzle | Line size(x″) | |||||||||||||||||||||

| 0 | No Request | 0 | CS | 0 | No Request | The most effective position for injection is generally at the center of the pipe | |||||||||||||||||||

| 1 | 1/4″ | 1 | 316SS | 1 | Open | ||||||||||||||||||||

| 2 | 1/2″ | 2 | 316LSS | 2 | Quill | ||||||||||||||||||||

| 3 | DSS | 3 | Cap & Core | ||||||||||||||||||||||

| 4 | INCONEL | ||||||||||||||||||||||||

| – Code | Type and Size of components connected to Tee and material of components | ||||||||||||||||||||||||

| Txx | Connection Size | Material | |||||||||||||||||||||||

| 0 | No Request | 0 | CS | ||||||||||||||||||||||

| 1 | 1/4″Nipple | a | 1/4″Nipple and Valve | 1 | 316SS | ||||||||||||||||||||

| 2 | 1/2″Nipple | b | 1/2″Nipple and Valve | 2 | 316LSS | ||||||||||||||||||||

| 3 | 3/4″Nipple | c | 3/4″Nipple and Valve | 3 | D SS | ||||||||||||||||||||

| 4 | 1″Nipple | d | 1″Nipple and Valve | 4 | INCONEL | ||||||||||||||||||||

| 5 | 1/4″SWN Flange* | e | 1/4″Nipple and Flange | ||||||||||||||||||||||

| 6 | 1/2″SWN Flange | f | 1/2″Nipple and Flange | ||||||||||||||||||||||

| 7 | 3/4″SWN Flange | g | 3/4″Nipple and Flange | ||||||||||||||||||||||

| 8 | 1″SWN Flange | h | 1″Nipple and Flange | ||||||||||||||||||||||

| For Example:SI-P221-N12-S122-L4″-T22 SI:Sampling & Injection Assembly,P221: Solid Plug Body in 316LSS Viton O-Ring and PTFE Primary Packing,N12:Injection Nut Connection Size is 1/4″and Material is 316LSS,S122:Injection Tube Connection Size is 1/4″ and Material is 316LSS.Type of nozzle is quill,L4″:For 4″pipe. T22: Connection Size of Nipple connected to Tee is 1/2″NPT(M), Nipple material is 316LSS | |||||||||||||||||||||||||

Note: SWN Flange is special WN Flange

Example for a set of Sampler & Injector Assembly:

EMT-CIPA-0F600#RF-2-1+ SI-P221-N12-S122-L4″-T22