Description

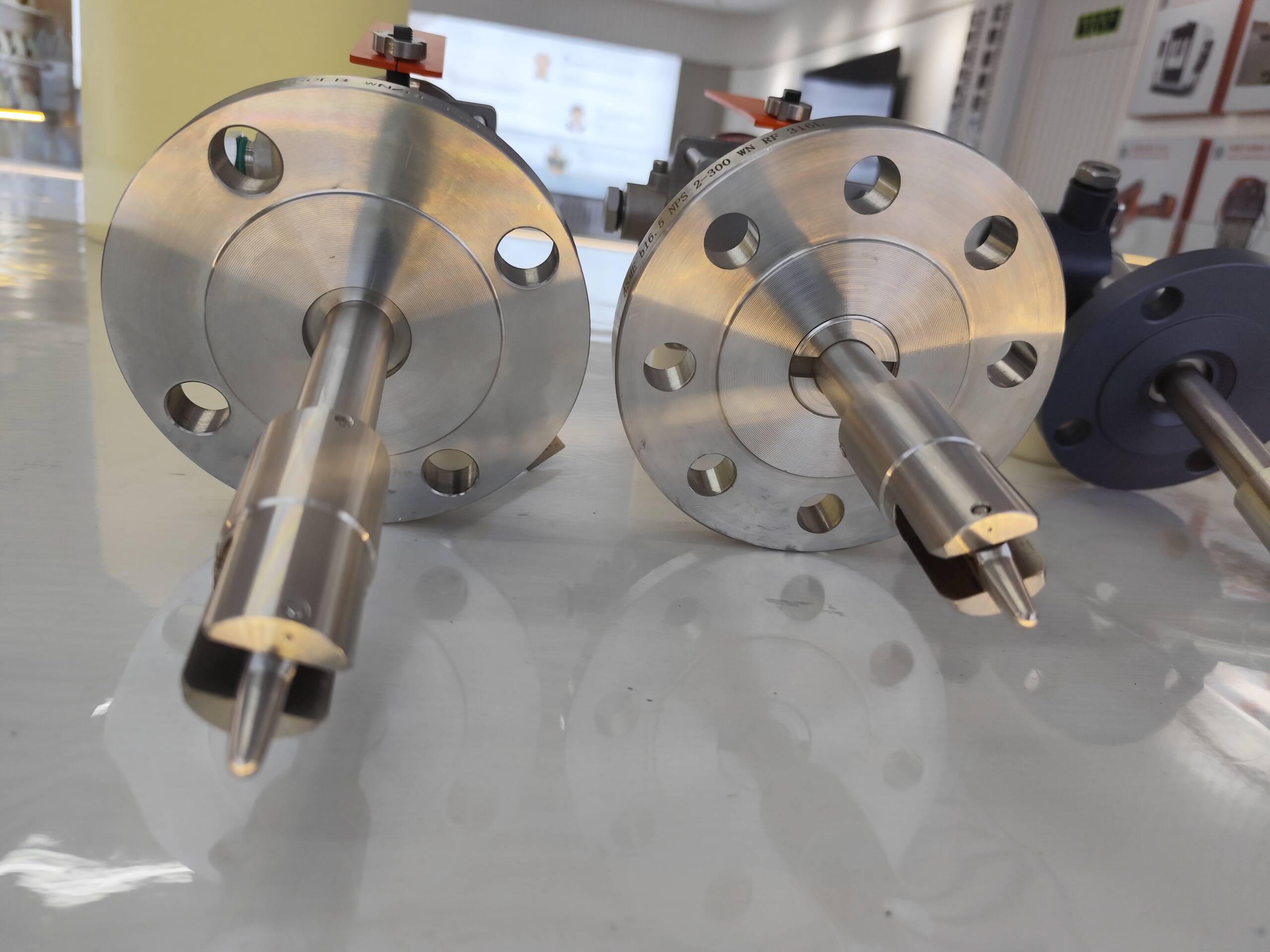

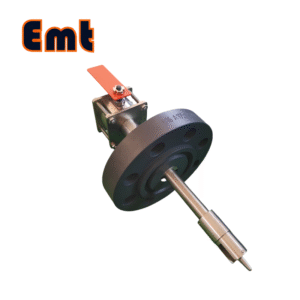

EMT Intrusive Pig Detector serves as a critical monitoring device in pipeline operations, providing confirmed passage detection of cleaning and inspection pigs. Installed at key locations including launching stations, receiving terminals, and critical intermediate points, these detectors deliver essential operational data for pipeline maintenance and integrity management.

1. Technical Specifications

Construction & Materials

-

Connection Type: Flange connection

-

Body Length: 200mm standard

-

Operating Temperature: -20°C to +120°C (custom ranges available)

-

Adjustment Range: 0-21mm for bidirectional models

-

Insert Depth: 21mm (bidirectional), 13mm (unidirectional)

Material Options

-

Stainless Steel 304 & 316: For general corrosion resistance

-

Duplex Stainless Steel F51: Enhanced strength and corrosion resistance

-

Carbon Steel A105N: Cost-effective option with good performance

-

Inconel 625: Superior resistance to extreme temperatures and corrosion

Compliance Standards

-

NACE MR 01-75 compliant

-

IP65/IP66 ingress protection

-

ExdⅡ BT4 explosion-proof classification

2. Design Features of Pipeline Pig Detector

Adjustable Detection System

The detector’s 0-21mm adjustable range accommodates varying pipeline wall thicknesses, providing versatility across different pipeline systems without requiring specialized units.

Robust Material Selection

Each material option is engineered for specific operational environments:

-

Stainless steels for general corrosive conditions

-

Duplex steel for more aggressive environments

-

Inconel for extreme temperature and corrosion applications

Installation & Maintenance

-

Lightweight design simplifies installation

-

Flexible configuration adapts to complex pipeline layouts

-

Manual reset capability for straightforward maintenance

3. Industry Applications of Pipeline Pig Detector

Oil & Gas Pipelines

-

Preventive maintenance tracking

-

Inspection pig monitoring

-

Safety compliance verification

-

Deposit buildup prevention

Water & Sewage Systems

-

Blockage prevention in wastewater lines

-

Maintenance cycle verification

-

Leak detection support

-

System integrity monitoring

Chemical Processing

-

Contamination prevention

-

Pipeline integrity assurance

-

Operational efficiency maintenance

-

Corrosion monitoring

Additional Sectors

-

Food and beverage processing

-

Pharmaceutical manufacturing

-

Industrial processing lines

4. Operational Benefits of Pipeline Pig Detector

Reliable Performance

-

Consistent detection accuracy

-

Durable construction for long service life

-

Adaptable to various pipeline conditions

Safety Compliance

-

Explosion-proof certification for hazardous areas

-

Corrosion-resistant materials for harsh environments

-

Pressure-rated design for pipeline conditions

Maintenance Advantages

-

Straightforward installation process

-

Minimal maintenance requirements

-

Easy reset and servicing procedures

Technical Support

-

Application-specific product selection

-

Installation guidance and support

-

Maintenance procedure training

-

Technical documentation