Description

Introduction to Hydraulic Chemical Injection Quill

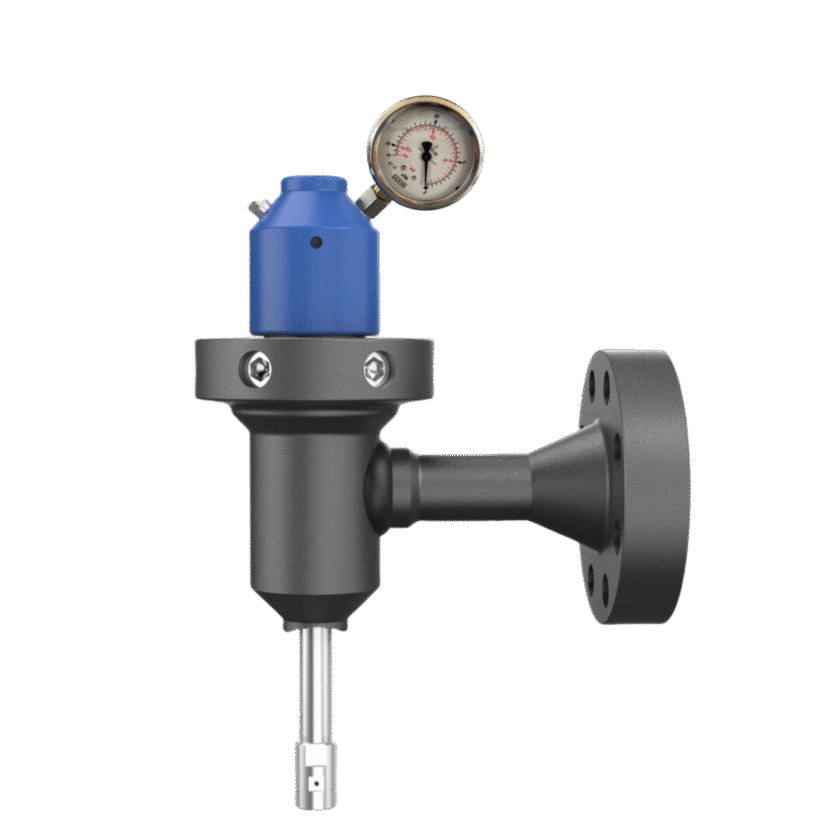

Hydraulic Chemical Injection Quill plays a crucial role in modern industrial processes. They ensure the precise injection of chemicals into a pipeline or reactor. This precision helps maintain system efficiency and protects against corrosion and scaling. Industries such as oil and gas, water treatment, and manufacturing rely on these tools. They keep their operations smooth and their equipment in top condition.

Design and Functionality

The design of Hydraulic Chemical Injection Quill is both sophisticated and practical. They consist of a long, narrow tube that extends into the pipeline. This setup allows the quill to inject chemicals directly into the fluid stream. Manufacturers craft these quills from robust materials like stainless steel or special alloys. These materials resist the harsh chemicals and high pressures they encounter. Each quill features a check valve at the tip to prevent backflow. This design ensures that chemicals only move in the intended direction.

Operational Benefits of Hydraulic Chemical Injection Quill

Using a hydraulic chemical injection quill brings numerous operational benefits. Firstly, it offers a controlled way to introduce chemicals into a system. This control is essential for processes that require precise chemical dosing. The quill’s precise injection points help disperse chemicals evenly. This even dispersion is necessary for effective treatment and minimal chemical waste. Furthermore, the integration of quills into systems is straightforward. This ease of integration ensures minimal downtime during installation or maintenance.

Parameters of Hydraulic Chemical Injection Quill

| Category | Details |

| Product Information | |

| Product Name | Chemical Injection Quill |

| Brand Name | EMT Pigging |

| Condition | New |

| Type | Injection & Sampling System |

| Certification | ISO 9001 |

| Warranty | 1.5 years |

| Place of Origin | Liaoning, China |

| Physical Specifications | |

| Weight (KG) | 5 |

| Package Size (cm) | 35 x 40 x 60 |

| Gross Weight (Package, kg) | 8 |

| Material and Construction | |

| Sealing Material | Fluororubber |

| Solid Plug Assembly | 316L Stainless Steel |

| Injection Tube | 316L Stainless Steel |

| NPT Nozzle | 316L Stainless Steel |

| Flange Material | ASTM A105N |

| Operational Parameters | |

| Working Temperature (°C) | -20 to 200 |

| Operation Temperature (°C) | -20 to 150 |

| Working Pressure (LB) | 150LB, 300LB, 600LB, 900LB, 1500LB |

| Pressure Rating (PSI) | 6000 PSI or as per Flange Size |

Safety and Efficiency

Safety is a paramount concern when handling chemicals, and hydraulic chemical injection quills address this directly. They keep the chemicals contained and prevent any potential exposure to the environment or workers. This containment reduces the risk of chemical spills or leaks. Additionally, the efficiency of chemical use improves with quills. They deliver chemicals at the point of need, reducing the required quantities and associated costs. This efficiency not only saves money but also minimizes the environmental impact of chemical processes.

Applications and Considerations

Hydraulic chemical injection quills find applications in a wide range of industries. In the oil and gas sector, they help in the precise dosing of inhibitors that prevent pipe corrosion. In water treatment facilities, quills inject chlorine or other disinfectants to ensure water safety. When selecting a quill, it’s important to consider the specific chemicals and pressures your system will encounter. The compatibility of materials and the design of the quill are critical to ensure long-term reliability and performance.

In conclusion, hydraulic chemical injection quills are indispensable in many industrial applications. They ensure the effective, safe, and efficient delivery of chemicals into critical processes. Their robust design and precise functionality make them a key component in maintaining the health and efficiency of industrial systems.