Description

EMT Injection Quills provide safe and efficient chemical injection capabilities for pipeline systems without requiring process shutdown. These specialized access fittings enable reliable chemical dosing while maintaining full operational continuity. Engineered for durability and performance, our injection quills support optimal chemical treatment programs across various industries, particularly in oil and gas production, chemical processing, and industrial applications where uninterrupted operations are critical.

Technical Specifications

Construction & Materials

Construction & Materials

-

Material Options:

-

Carbon Steel (CS)

-

Stainless Steel 316/316L

-

Duplex Stainless Steel

-

Inconel 625

-

-

Temperature Range: -20°C to +120°C

-

Connection Types:

-

2″ Welded connection

-

2″ ANSI Flange connection

-

-

Pressure Ratings: Standard 600# RF (other ratings available)

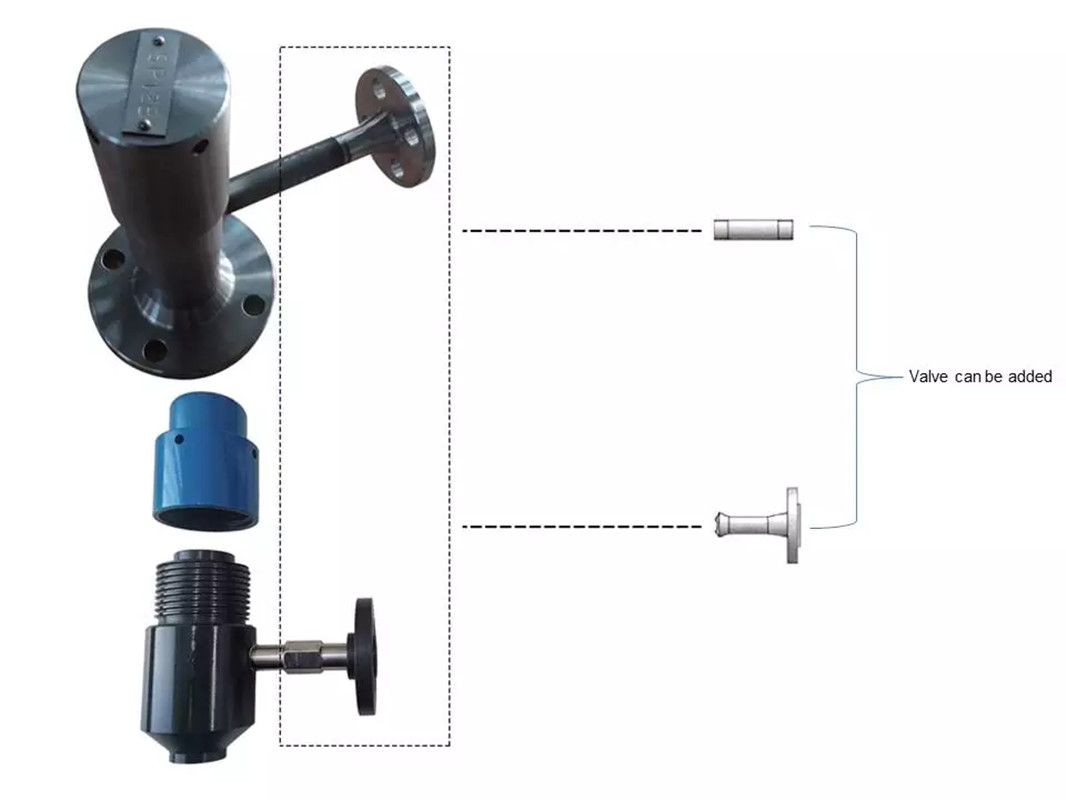

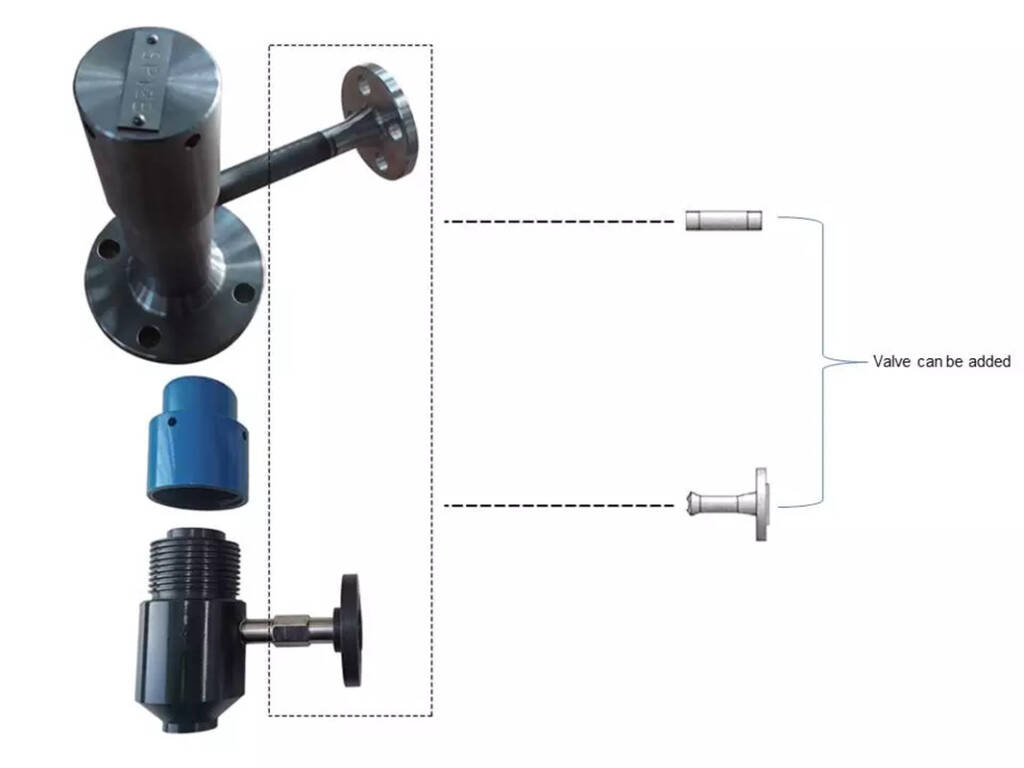

Configuration Options

-

Tee Sizes: 1/4″, 1/2″, 3/4″, 1″ NPT

-

Protective Covers:

-

Basic cover without hole

-

Cover with access hole

-

Bleed valve configuration

-

Bleed valve with pressure gauge

-

Key Features

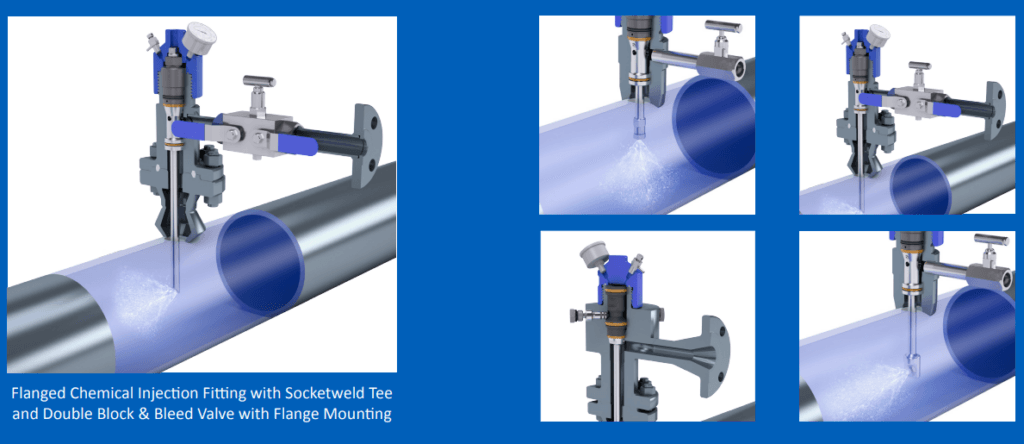

Pressure-Rated Disassembly Capability

The EMT Injection Quill system features an integrated valve mechanism that allows safe disassembly and maintenance while the pipeline remains operational and under pressure. This innovative design eliminates the need for process shutdown during maintenance activities, significantly reducing downtime and production losses. The pressure-containing design ensures operational safety while providing full access for inspection and replacement.

Robust Material Construction

Manufactured from industry-proven materials selected for specific application requirements:

-

Stainless Steel 316/316L: Optimal corrosion resistance for most chemical applications

-

Duplex Stainless Steel: Enhanced strength and corrosion resistance for harsh environments

-

Carbon Steel: Cost-effective solution for non-corrosive services

-

Inconel 625: Superior performance in extreme temperature and corrosive conditions

Standardized Modular Design

The quill system follows standardized dimensions and pressure ratings, enabling:

-

Simplified inventory management

-

Easy replacement and maintenance

-

Compatibility with existing systems

-

Rapid deployment and installation

Benefits of Injection Quills

Continuous Operation Assurance

-

No production interruption during installation or maintenance

-

Safe disassembly under full operating pressure

-

Minimal impact on production schedules

-

Reduced operational downtime costs

Enhanced Safety Performance

-

Integrated bleed valve for safe pressure relief

-

Robust construction withstands process conditions

-

Leak-proof connections ensure environmental protection

-

Compliance with industry safety standards

Cost-Effective Maintenance

-

Lower total cost of ownership compared to flange-connected systems

-

Reduced maintenance labor requirements

-

Extended service life through durable materials

-

Minimal replacement part requirements

Application of Injection Quills

Oil & Gas Production

-

Scale and corrosion inhibitor injection

-

Production chemical dosing

-

Well treatment chemical injection

-

Pipeline integrity chemical programs

Chemical Processing

-

Catalyst and additive injection

-

Process chemical dosing

-

pH adjustment chemical injection

-

Specialty chemical introduction