Description

EMT offers a customizable and efficient solution for pipeline maintenance with its Bidirectional Pigging Pigs, designed to cater to a wide range of pipe sizes from 2-60 inches. Tailored specifically to meet individual customer requirements, these cleaning pigs are ideal for diverse industries including oil & gas pipelines, energy & mining, construction works, and building material shops.

Key Features and Benefits of Bidirectional Pigging Pigs

- Customized Size Options. Customers can choose from standard sizes or request custom dimensions to suit specific pipeline needs, ensuring optimal compatibility and performance.

- Durability and Cost Efficiency. These Bidirectional Pigging Pigs not only last long but also offer cost-effective performance, making them a practical choice for regularly handling demanding environments.

- Certified Quality. Each pig is manufactured to comply with ISO 9001 standards, affirming its quality and reliability. This certification guarantees that all products meet international quality specifications.

- Comprehensive Accessories. The package includes six discs among other main accessories, providing a complete set-up for effective pipeline cleaning and maintenance.

- Pre-Shipment Inspection. To further ensure customer satisfaction and product reliability, EMT conducts a thorough machinery test report and video outgoing inspection before shipment, offering customers complete peace of mind regarding their purchase.

Additional Customization Options of Bidirectional Pigging Pigs

EMT’s range of polyurethane pipe cleaning pigs showcases a comprehensive suite of designs tailored to meet a diverse array of pipeline cleaning challenges across various industries. The selection includes foam pigs, solid cast pigs, cup cleaning pigs, disc cleaning pigs, and combined pigs, each engineered to optimize cleaning efficacy for specific conditions and types of residue.

Detailed Overview of Pig Types

- Foam Pigs. These are lightweight and flexible, making them ideal for lighter cleaning and drying tasks. Foam pigs can navigate smaller diameter pipes and moderate bends, which makes them suitable for a wide range of applications, including routine maintenance and drying after hydrostatic testing.

- Solid Cast Pigs. Known for their durability and ruggedness, solid cast pigs work in applications requiring aggressive scraping and heavy-duty cleaning. They are particularly effective in removing hardened deposits and scale from the pipeline walls.

- Cup Cleaning Pigs. These pigs feature flexible cups that maintain close contact with the pipe walls, effectively scraping and removing debris. Cup pigs are versatile and can be used in both liquid and gas pipelines, making them suitable for a variety of cleaning scenarios.

- Disc Cleaning Pigs. Equipped with rigid discs, these pigs provide thorough scraping action against tough residues. They can handle high-pressure environments and are effective in maintaining pipeline integrity by preventing deposit build-up.

- Combined Pigs. Combining features from various pig types, these are multifunctional and can be tailored to perform specific cleaning, drying, or batching operations within a pipeline. This versatility makes them highly valuable for complex pipeline maintenance programs.

Enhanced Functionality with Additional Features

To further increase the utility and performance of these cleaning pigs, EMT offers the option to incorporate several advanced features into the pig design:

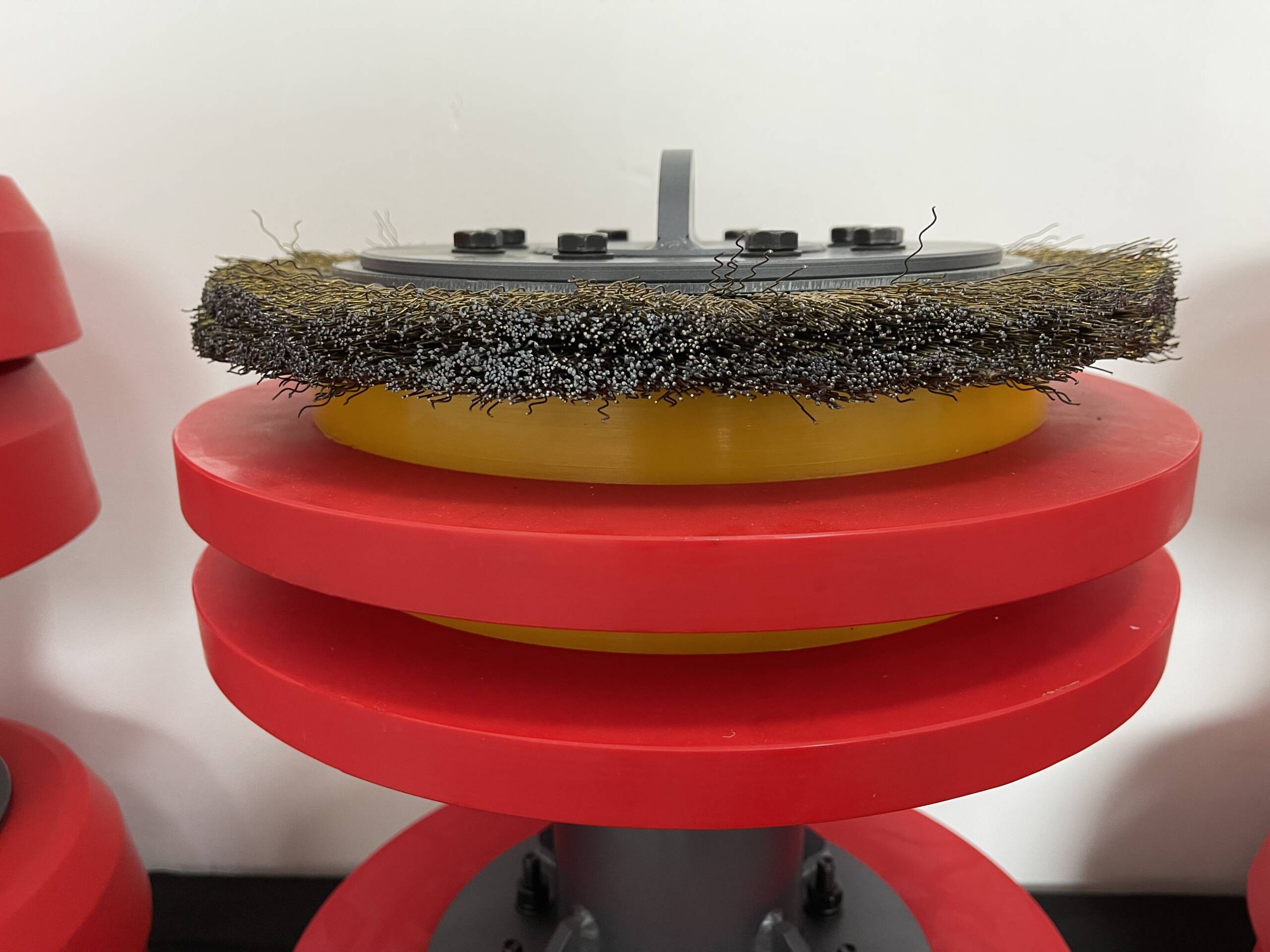

- Brushes. For more rigorous cleaning tasks, brushes can be added to any pig type. These are particularly useful for removing encrusted deposits and improving the overall cleaning quality of the pipeline.

- Transmitters. Transmitters can be embedded in the pigs for precise location tracking. This technology is vital for monitoring the pig’s journey through the pipeline. It ensures that every section is properly cleaned and that no parts of the pig are lost in the system.

- Gauging Discs. These can assess the internal condition of the pipeline. Gauging discs can detect anomalies such as dents, corrosion, or other forms of wear, which are critical for maintaining pipeline integrity.

- Magnetic Steel. Incorporating magnetic steel helps in attracting and removing ferrous debris from the pipeline. This feature is particularly important in pipelines that transport ferrous materials, as it helps prevent damage to the pipeline and the pig itself from sharp metallic debris.

Application of Bidirectional Pigging Pigs

Bidirectional pigging pigs are versatile and essential tools designed for the maintenance and operational efficiency of pipeline systems in various industries, including oil and gas, energy, mining, and construction. These tools are engineered to navigate through complex pipeline geometries, ensuring they provide thorough cleaning and maintenance. By removing debris, residues, and build-ups effectively, bidirectional pigging pigs prevent potential blockages that can disrupt the flow and efficiency of pipeline operations.

The unique bidirectional capability of these pigs allows them to travel in both directions within the pipeline. This feature is particularly beneficial because it enhances the thoroughness of the cleaning process and allows for the flexibility of launching and receiving from either end of the pipeline, reducing the need for additional infrastructure and simplifying operations.

Customization options for these pigs are broad, accommodating a range of pipe sizes and specific operational requirements. This adaptability ensures that they can be tailored to the precise needs of different pipeline systems, enhancing their effectiveness. Various functional components such as:

- Brushes. These work for more aggressive cleaning tasks, capable of scrubbing hard-to-remove residues off the pipeline walls.

- Gauging Discs. These are vital for assessing the internal condition of the pipe, helping to identify areas of corrosion or other damage that may require attention.

- Transmitters. These devices are also integrated for tracking purposes, allowing operators to monitor the pig’s location throughout the cleaning process. Which is crucial for ensuring the pigging operation is proceeding as planned.

Furthermore, the inclusion of magnetic elements helps in collecting ferrous debris within the pipeline. Which is especially useful in maintaining the integrity of the pipeline by preventing damage that these particles might cause.