Description

Pipeline Corrosion Coupons from EMT-CI are integral tools designed to accurately monitor corrosion rates and gauge the health of pipelines and containers. These devices are crucial for predicting material degradation and effectively planning maintenance to extend the life of pipeline systems.

Access Fitting Body

| Model | ||||||

| EMT-CIPA | Access Fitting Body of Pipeline Corrosion Coupons | |||||

| – The material of Access Fitting Body | ||||||

| 0 | CS | |||||

| 1 | 316SS | |||||

| 2 | 316LSS | |||||

| 3 | DUPLEX SS | |||||

| The Type of Access Fitting Body | ||||||

| B | 2″Welded(suffix “pressure rating” can be added to B) | |||||

| F | 2″ANSI Flange(suffix “pressure rating & sealing type” can be added to F) | |||||

| -Tee Size- pressure rating & sealing type if flanged end | ||||||

| 0 | No Tee | |||||

| 1 | 1/4″NPT(F)Tee | |||||

| 2 | 1/2″NPT(F)Tee | |||||

| 3 | 3/4″NPT(F)Tee | |||||

| 4 | 1″NPT(F)Tee | |||||

| 5 | Hole for 1/4″SWN Flange | |||||

| 6 | Hole for 1/2″SWN Flange | |||||

| 7 | Hole for 3/4″SWN Flange | |||||

| 8 | Hole for 1″SWN Flange | |||||

| -Protective Cover Type/ Material | ||||||

| 0 | No Protective Cover | Material | ||||

| 1 | Without hole | CS or 0 | ||||

| 2 | With hole | SS or 1 | ||||

| 3 | Bleed Valve | DSS or 3 | ||||

| 4 | Bleed Valve, & Pressure Gauge | |||||

| For Example:EMT-CIPA-0F600#RF-2-1/CS shows 2″ANSI 600#RF Flange Access Fitting Body in CS, 1/2″NPT(F)Tee, Protective Cover in CS without hole

0F600#RF: 0F_ Access Fitting Body is Flanged in CS , 600#RF _Size is 2″ANSI 600#RF , 2:Tee size is 1/2NPT(F) 1: Protective cover type is without hole /CS: Protective cove material in CS |

||||||

Key Features of EMT-CC Pipeline Corrosion Coupons

- Accurate Corrosion Monitoring:Engineers specifically engineer the Pipeline Corrosion Coupons to measure the corrosion rate in mils-per-year, providing essential data on how quickly the pipeline material deteriorates.

This information is critical for assessing the remaining lifespan of the pipeline components.

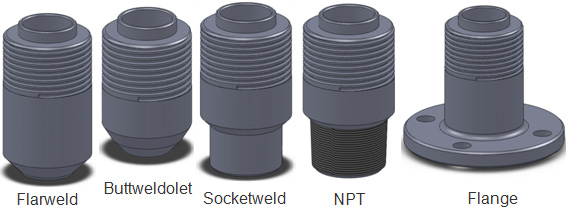

- Flexible Installation Options: Engineers can integrate these corrosion coupons into the pipeline system either by welding or mounting them using flange-mounted access fitting bodies. This versatility allows deployment in various pipeline configurations, enhancing their utility across different industrial applications.

- High-Pressure Resistance: The corrosion coupons are integral components of a robust high-pressure access system that includes an access fitting body, a plug assembly, and a cover. Together, these components are built to withstand a range of pressure ratings from 150LB up to 1500LB.

- Durable Materials and Effective Seals: Constructed using industry-specified materials, the corrosion coupons feature seals made from Fluororubber and Teflon, both of which are famous for their exceptional resistance to harsh chemicals and their ability to operate within a temperature range of -20 to 200°C. Consequently, these materials help ensure the integrity and longevity of the coupons under adverse conditions.

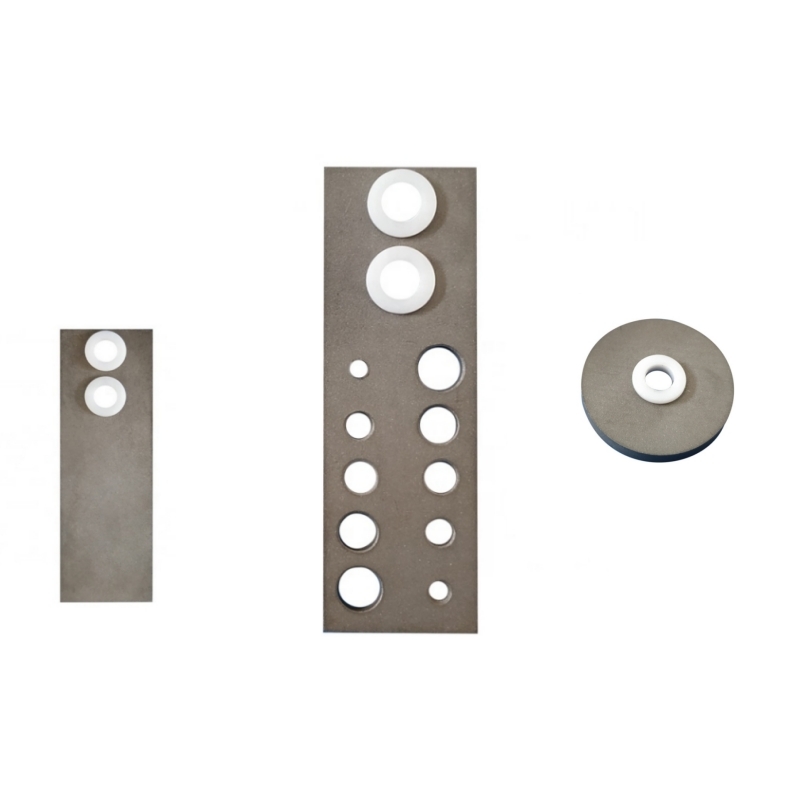

- Customizable and Versatile: The coupons and their holders are available in several dimensions (such as 3″x1″x1/8″ and 2″x1″x1/8″) and can accommodate both rectangular and circular shapes. This adaptability allows for precise corrosion monitoring tailored to specific pipeline geometries and conditions.

- Comprehensive System Design: Each component of the corrosion coupon system is meticulously designed to function seamlessly within the pipeline. The internal assembly includes a solid plug body, an O-Ring, PTFE primary packing, a coupon holder (available in both fixed and adjustable forms), and necessary fastening hardware, ensuring a secure and reliable fit.

Components of EMT-CC Pipeline Corrosion Coupons

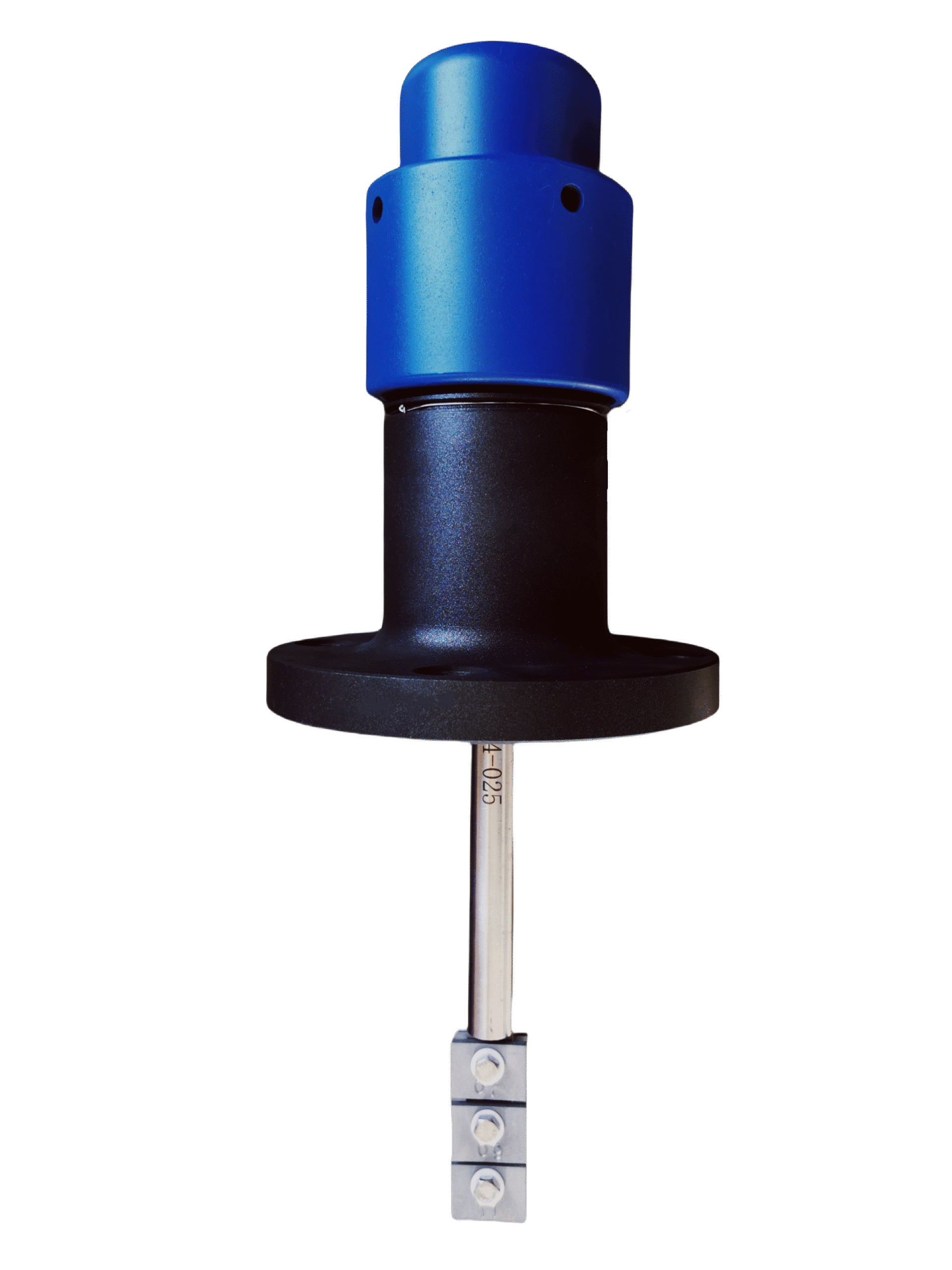

High Pressure Access System:

The installation of EMT-CI Corrosion Coupons involves a high-pressure access system that comprises:

- Access Fitting Body: Available as either welded or flange-mounted, facilitating versatile installation options to suit various pipeline configurations.

- Plug Assembly: A critical component that ensures a secure and pressure-resistant seal within the pipeline.

- Cover: Protects the internal components from external environmental influences, ensuring the longevity and reliability of the system.

Internal Assembly Details:

The internal assembly of the Corrosion Coupons includes several key components:

- Solid Plug Body: Forms the core structure of the coupon assembly.

- O-Ring and PTFE Primary Packing: These elements actively seal the system, prevent leaks, and isolate the coupons from external contaminants.

- Coupon Holder: Available in fixed or adjustable versions to accommodate different sizes and shapes of coupons, enhancing the flexibility of the system.

- Coupon: The actual material sample that is exposed to the pipeline environment to measure corrosion rates.

- Bolt, Nut, and Isolation Gasket: These components secure the coupon in place and ensure a tight seal, protecting the integrity of the measurement.