Description

1. Introduction

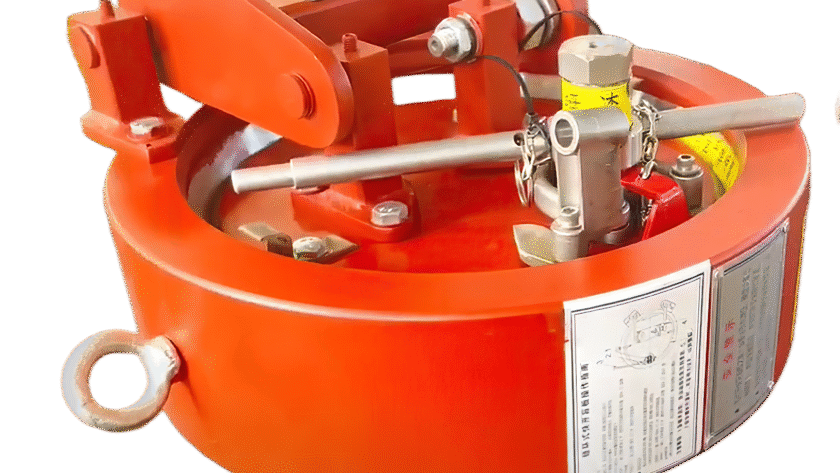

The EMT Bandlock Quick Opening Closure is engineered for efficiency and safety in industrial applications, particularly suited for pipeline pigging systems within the oil, gas, and mining industries, as well as construction works and building material shops. This product features a robust horizontal lock type and EMT also can tailor to meet the rigorous demands of industrial pipeline cleaning.

2. Specifications

- Type: Horizontal Type Quick Opening Closure

- Brand: EMT Pigging

- Weight: 40 kg

- Dimensions: Offered in a customizable size; typical packaging is 80x80x80 cm.

- Design Pressure: Ranges from 1.6 MPa to 30 MPa.

- Corrosion Allowance: 2 mm.

- Seismic Fortification Intensity: Rated up to 7 degrees.

- Certifications: ISO9001 certified, ensuring compliance with international quality standards.

3. Features

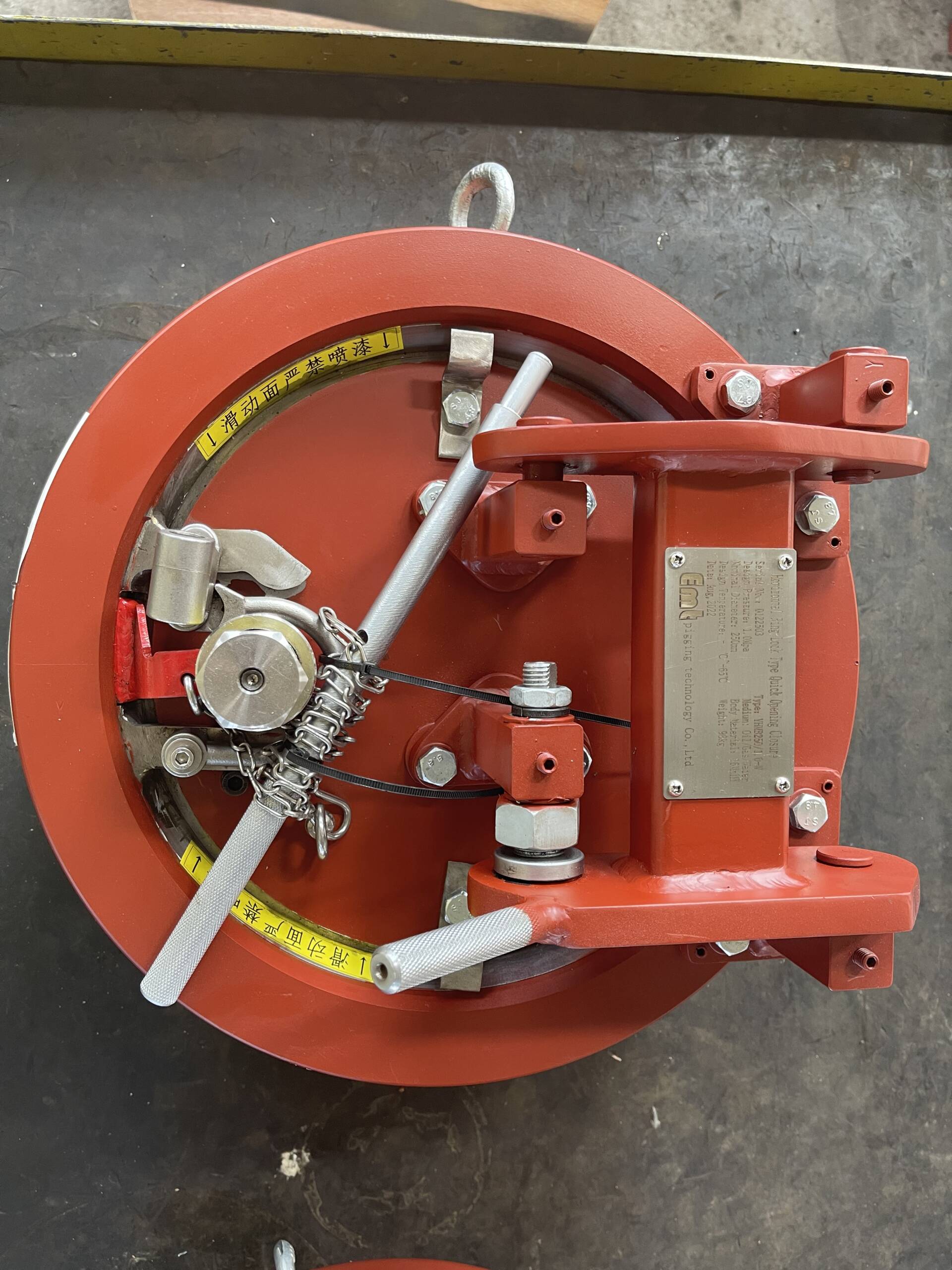

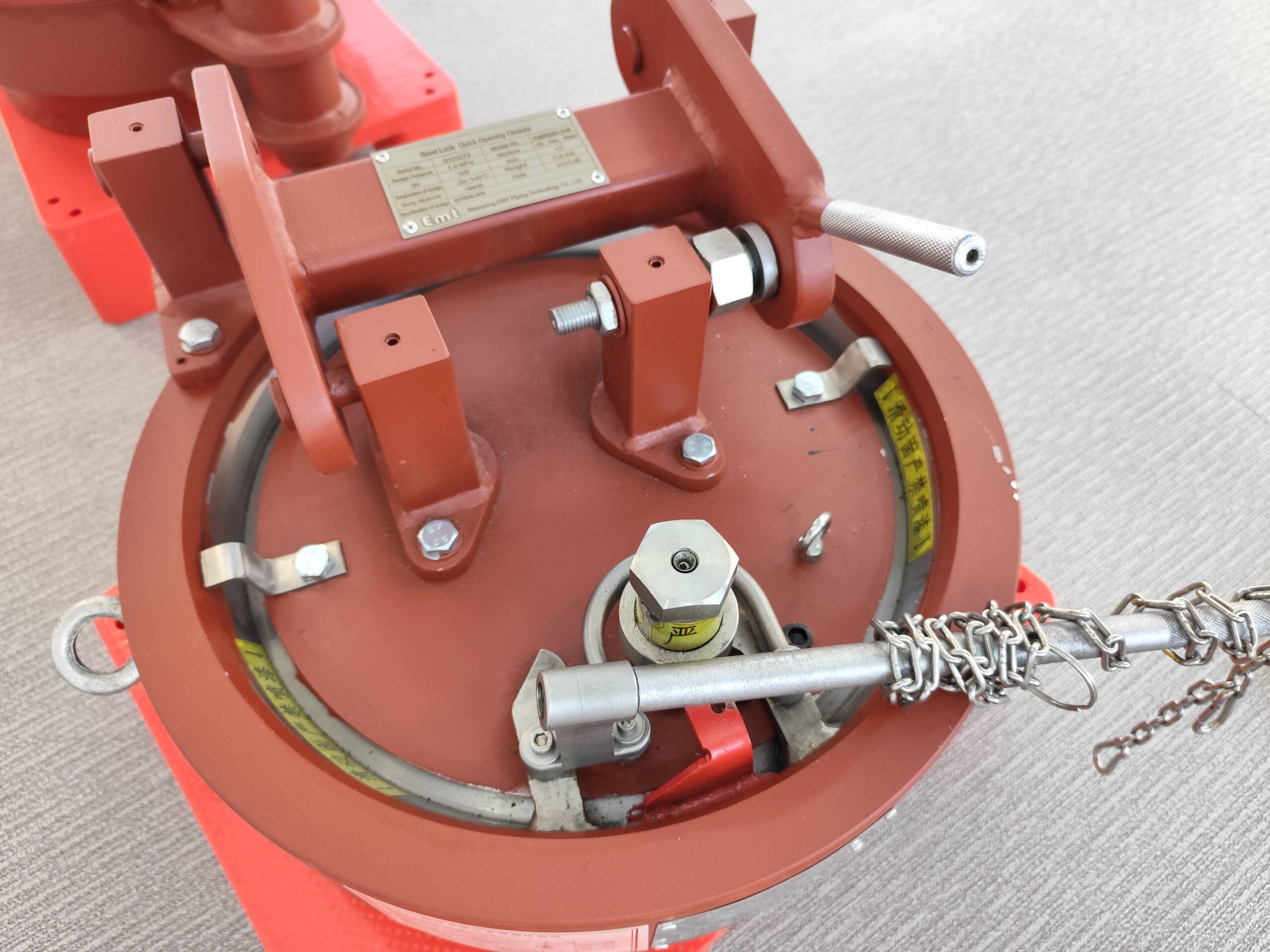

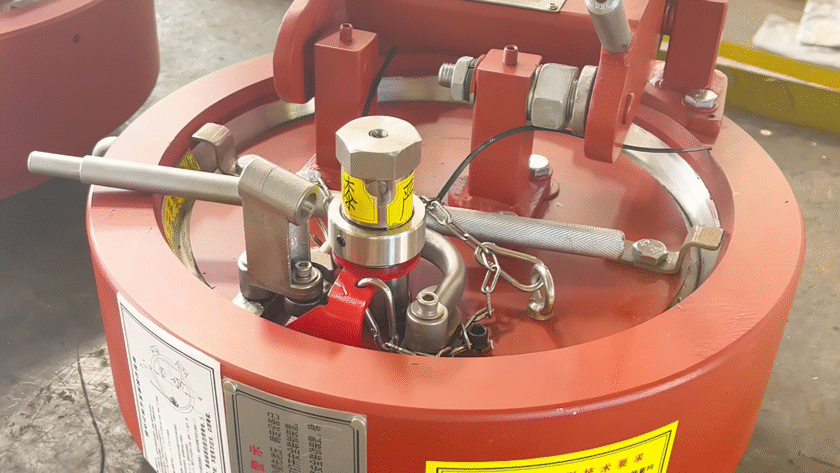

Operating Mechanism

The EMT Bandlock Quick Opening Closure incorporates a highly efficient scalable locking-ring structure. This advanced mechanism is to drastically cut down operation time, enabling quick access to pipeline systems. People can open the closure and securely close it in under 60 seconds with minimal effort, requiring less than 200N of force. This feature makes it particularly suitable for rapid operations in field conditions where time and ease of access are critical. The design is streamlined to ensure that even operators working alone can manage the opening and closing procedures swiftly and safely. It enhances the overall productivity and reducing downtime.

Sealing Technology

At the core of the EMT Bandlock Closure is its state-of-the-art sealing technology. Which features a unique self-tightening lip seal. This seal is engineered to automatically tighten under pressure, thus improving its integrity and reliability under variable operational pressures. The sealing mechanism is designed to adapt to fluctuations in pressure and temperature, maintaining a tight seal to prevent leaks and ensure safety throughout its operation. This technology not only enhances the safety and reliability of the seal but also extends the lifespan of the seal itself, reducing the need for frequent replacements and maintenance.

Safety Features

Safety is paramount in the design of the EMT Bandlock Quick Opening Closure. It includes a comprehensive safety lock system equipped with a self-locking function that is critical during both the boosting and depressurizing phases of pipeline operations. The locking mechanism must be correctly engaged to initiate boosting. Which prevents accidental opening or misoperation that could lead to safety incidents. Furthermore, the closure is designed to ensure complete depressurization of the container before the blind flange cover can be opened. This two-stage safety mechanism guarantees that all internal pressure is safely vented before any maintenance or inspection procedures begin, thereby protecting the operators and the environment from potential hazards caused by sudden release of contents.

Material and Customization

The material composition of the EMT Bandlock Quick Opening Closure can be tailored to meet specific requirements of different industries and applications. Options include various grades of stainless steel, carbon steel, and other alloy materials that offer resistance to corrosion, wear, and extreme environmental conditions. Customization extends to the size, pressure ratings, and specific configurations required by clients, allowing the closure to be perfectly matched to the technical specifications and operational demands of particular projects. This level of customization ensures optimal performance, maximized safety, and compliance with industry-specific regulations. Which makes it a versatile choice for a broad range of industrial applications.

4. Additional Information

- Place of Origin: Liaoning, China

- Warranty: 1.5 years

- Minimum Order Quantity: 1 set

- Packaging: Sold as a single item with a gross weight of 15 kg.

- Port: Dalian, China

5. Application

Oil and Natural Gas Industry

In the oil and natural gas sector, the EMT Bandlock Closure works primarily in pipeline systems for pig launching and receiving operations. These operations are critical for the cleaning and maintenance of pipelines, ensuring that they operate efficiently and safely by removing deposits and inspecting the integrity of the pipe. The quick opening feature allows for rapid access to the pipeline, significantly reducing downtime and enhancing productivity during routine maintenance or emergency interventions.

Water Treatment Facilities

Water treatment plants utilize the EMT Bandlock Closure in various parts of the treatment process. Especially in sludge handling and chemical dosing areas. The closures provide secure and quick access to filtration systems, tanks, and pipelines that require regular inspection and maintenance. The self-sealing and safety locking features ensure that these systems are operated safely, maintaining the integrity and cleanliness of the water treatment process.

Ore Pulp Processing

In the mining industry, particularly in ore pulp processing, the EMT Bandlock Closure works in the transportation and processing pipelines that handle abrasive slurries. The durability of the customized material options makes it ideal for withstanding the harsh conditions and abrasive nature of ore pulp. Which can quickly erode standard closures. So the quick opening mechanism is crucial for timely maintenance and clearing blockages, which are common in the mining industry.

Additional Industrial Applications

Beyond these primary industries, the EMT Bandlock Closure finds applications in other sectors requiring robust fluid handling solutions. Such as:

- Chemical Processing:

Handling aggressive chemicals demands closures that can resist corrosion and provide reliable sealing. The EMT Bandlock Closure’s customizable materials ensure compatibility with various chemicals, maintaining safety and operational integrity.

- Food and Beverage:

For applications involving large-scale fermentation tanks or storage vessels, the quick and secure access provided by the EMT Bandlock Closure facilitates easy maintenance and cleaning, crucial for maintaining hygiene standards.