Description

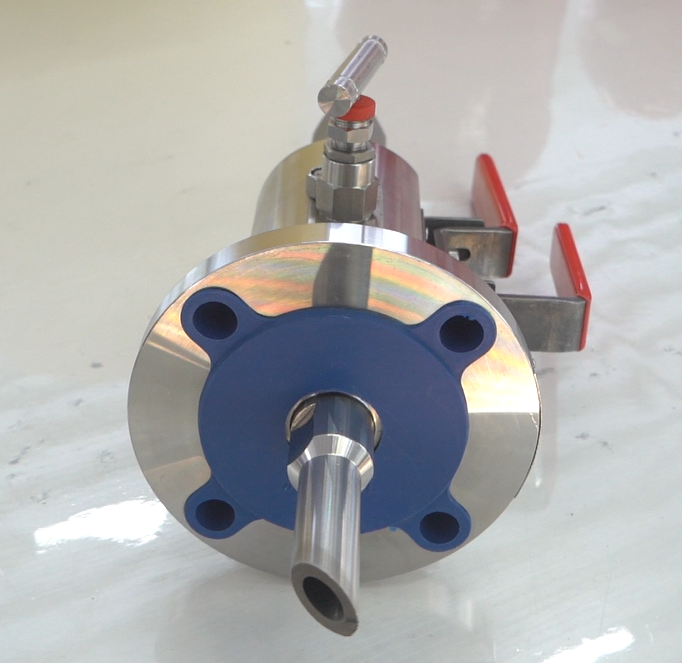

Chemical Injection Quills

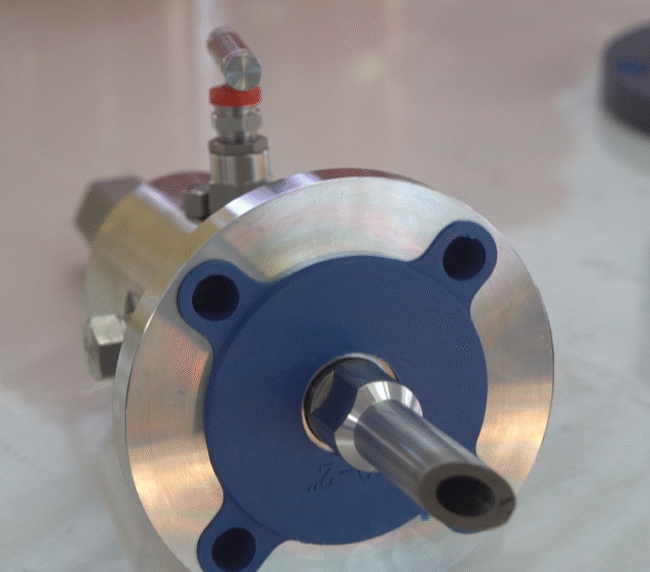

Chemical injection quills are crucial components in the maintenance and operation of pipelines, particularly in industries such as oil and gas, mining, and construction. These devices are designed to inject chemicals into a pipeline to control corrosion, manage flow efficiency, or add treatment chemicals to the transported fluid. The EMT Pigging brand offers a robust solution with its Chemical Injection Quill system, tailored for effective pipeline management.

Key Features and Specifications of Chemical Injection Quills

Product Name. EMT Pigging Chemical Injection Quill

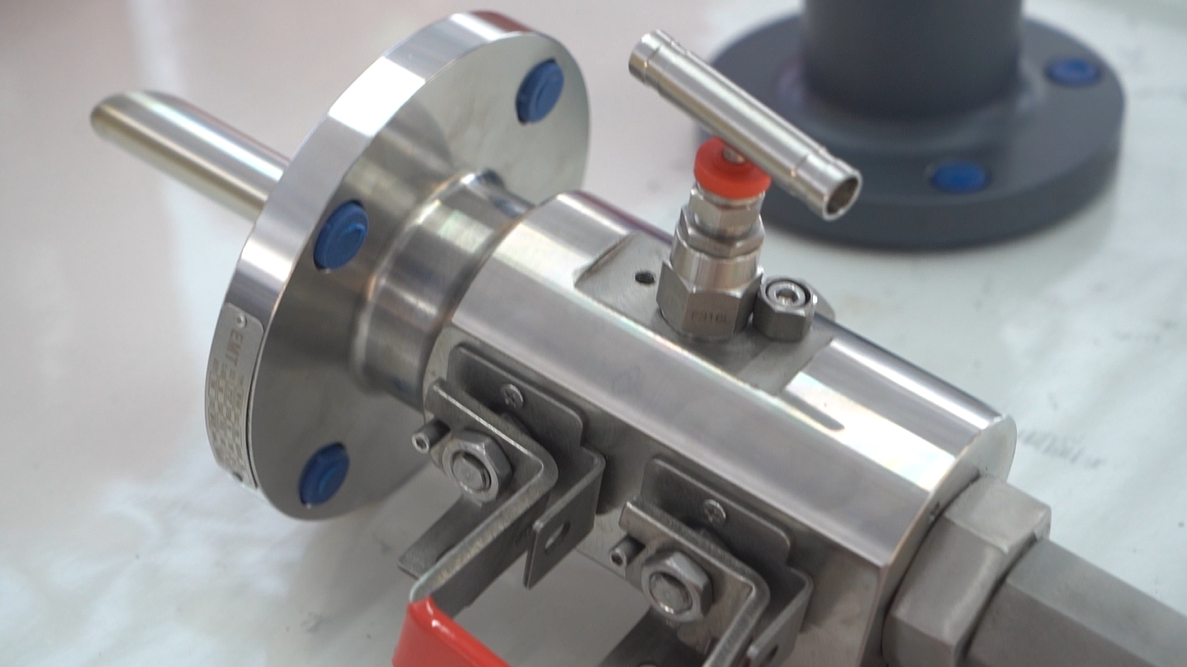

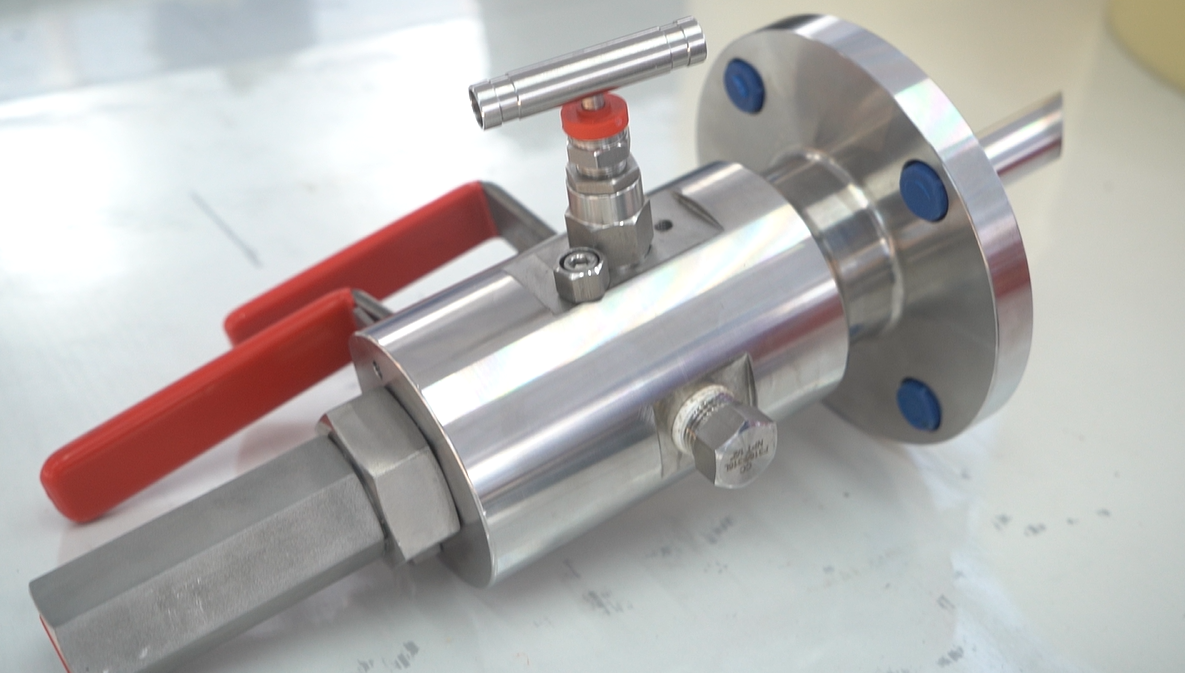

Material. Engineers construct the quills using high-grade 316L stainless steel for the solid plug assembly, injection tube, and NPT nozzle, ensuring durability and resistance to harsh chemicals. They use ASTM A105N to manufacture the flange, enhancing the system’s overall strength and compatibility with high-pressure environments.

(1) Sealing Material:

Fluororubber is used for its excellent resistance to high temperatures and chemical exposure, ensuring a reliable seal in diverse operating conditions.

(2) Working Conditions:

- Temperature. The quills can operate between -20°C to 200°C, accommodating a wide range of environmental conditions.

- Pressure. Available in pressure classes from 150LB to 1500LB, these quills can handle various operational demands, making them suitable for a broad spectrum of pipeline pressures.

(3) Application

(3) Application

- Corrosion Control. Corrosion is a major concern in pipeline systems, leading to potential failures and environmental hazards. The quills enable the injection of corrosion inhibitors directly into the pipeline, where they can effectively combat the corrosive effects of the transported media and the external environment.

- Cleaning and Maintenance. Regular maintenance tasks, such as cleaning with pipeline pigs and corrosion coupons, are facilitated by the use of these quills. They allow for the introduction of cleaning agents and specialized chemicals that help remove deposits, sludge, and other contaminants from the pipeline, ensuring optimal flow and reducing the likelihood of blockages and maintenance issues.

- Versatility in Chemical Handling. Designed to handle a variety of chemicals, the quills can be used to inject not only inhibitors but also biocides and other treatment chemicals as required by the specific conditions of the pipeline system. So this versatility makes them an indispensable tool in the ongoing effort to maintain pipeline integrity and efficiency.

Certification and Quality Assurance

EMT Pigging’s Chemical Injection Quills come with ISO9001 certification, ensuring compliance with international quality standards. The company provides a machinery test report and video outgoing-inspection as part of its commitment to quality assurance.

Advanced Attributes of Chemical Injection Quills

Packaging and Delivery

- Single Item Sales. Each quill is packaged and sold individually, allowing for precision quality control and verification before shipment.

- Packaging Specifications. The packaging dimensions are designed to protect the quill during transit. This size facilitates handling and ensures that the quill remains secure, minimizing the risk of damage.

- Delivery Assurance. Special attention goes into selecting packaging materials, incorporating impact-resistant and moisture-proof components to protect the quills from environmental factors and handling stresses during transit.

Chemical Injection and Sampling

The dual functionality of the EMT Pigging Chemical Injection Quill significantly enhances pipeline management strategies:

- Chemical Injection. These quills effectively enable the precise injection of chemicals into the pipeline, which is crucial for preventing corrosion, scaling, and biological growth. As a result, this capability is vital for maintaining the flow efficiency and integrity of the pipeline throughout its operational lifespan. Moreover, the quills can administer a wide range of chemicals—from inhibitors and biocides to conditioners—depending on the specific requirements of the pipeline system.

- Sampling Capability. In addition to chemical injection, the quills are designed to facilitate sampling of the pipeline medium. This feature allows operators to extract fluid samples without interrupting pipeline operations. Sampling is essential for ongoing monitoring of the fluid’s properties, enabling timely adjustments to the chemical treatment regimen and ensuring compliance with environmental and safety standards.

- Continuous Monitoring and Adjustment. The integration of injection and sampling functions allows continuous monitoring and real-time adjustment of pipeline conditions. This proactive pipeline management approach enables early issue detection and immediate corrective actions. As a result, it helps prevent costly downtime and extensive repairs.