Description

1. Introduction

The EMT Chemical Injection Quills are specifically designed to optimize the injection of chemicals into pressurized systems such as pipelines and vessels in various industrial settings. We use it to ensure that chemicals are delivered efficiently and safely into the central flow of a process system. Which is crucial for maintaining the integrity and performance of industrial operations.

2. Design Features of EMT Chemical Injection Quills

Material Construction

- Types of Materials Used: The EMT Chemical Injection Quills are typically made from high-grade materials like stainless steel and Hastelloy.

- Corrosion Resistance: Stainless steel offers excellent resistance to a wide range of chemicals and is also resistant to rust, which prolongs the life of the quill. Hastelloy, known for its superb corrosion resistance, is particularly useful in severe environments where stainless steel might fail.

- Durability: Both materials are not only resistant to corrosion but also exhibit high strength and durability under variable temperatures and pressures. This ensures that the quills can handle continuous use in industrial applications without degrading.

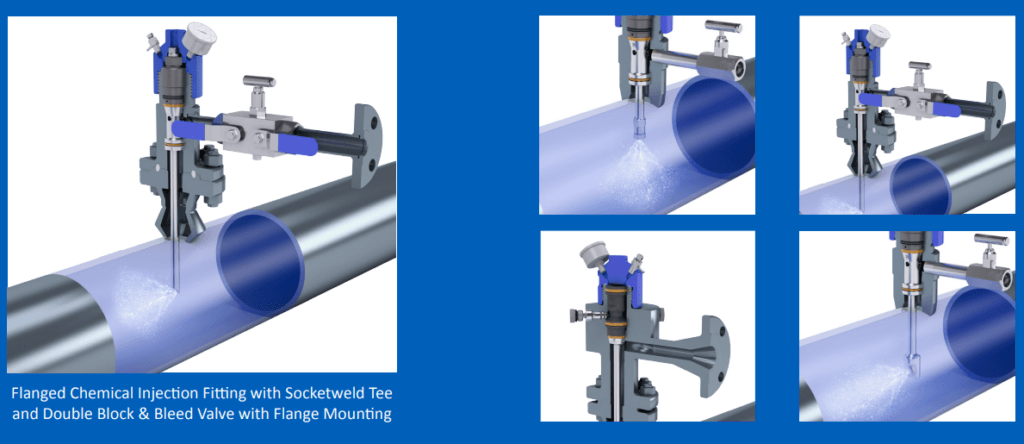

Retractable Functionality

- Easy Maintenance: The retractable design of the EMT Chemical Injection Quills allows for easy access to the quill for maintenance or replacement without the need to shut down the entire system. This design is particularly advantageous in continuous process industries where downtime can be costly.

- Safety: The ability to retract the quill reduces the risk of exposure to hazardous chemicals during maintenance. This feature enhances operational safety, protecting maintenance personnel from potential chemical spills or leaks.

- Operational Flexibility: Retractability provides flexibility in installation and maintenance. It allows for the quill to be inserted or removed easily according to the operational needs or during routine checks.

Adjustable Injection Depth

- Depth Control Mechanism: This feature includes a mechanism that allows operators to set and alter the depth at which the quill injects chemicals into the pipeline. This is crucial for ensuring the chemicals are introduced at the most effective point in the fluid stream.

- Enhanced Mixing: By adjusting the depth of insertion, the quill can release chemicals into areas of higher fluid dynamics, significantly improving the mixing and dispersion of chemicals. This is vital for processes where the homogeneity of the chemical mixture impacts the quality of the final product.

- Tailored Injection: The adjustable depth allows for better customization to specific process requirements. Depending on the fluid characteristics (such as flow rate, viscosity, and turbulence), the injection point can be optimized for maximum efficiency.

3. Operational Mechanism

Chemical Injection Process

Then here’s how it works:

- Point of Injection: The quill extends into the pipeline, positioning its outlet at the center or optimal point in the flow stream for even distribution of chemicals.

- Controlled Delivery: Chemicals are pumped through the quill under controlled pressure, which allows for precise dosing. The flow rate can be adjusted depending on the system’s requirements and the specific chemical reactions needed.

- Integration with System Controls: Often integrated with automated system controls, the quill can respond to real-time feedback from sensors monitoring flow rates, chemical concentrations, and other critical parameters. This integration helps maintain the correct chemical dosage automatically.

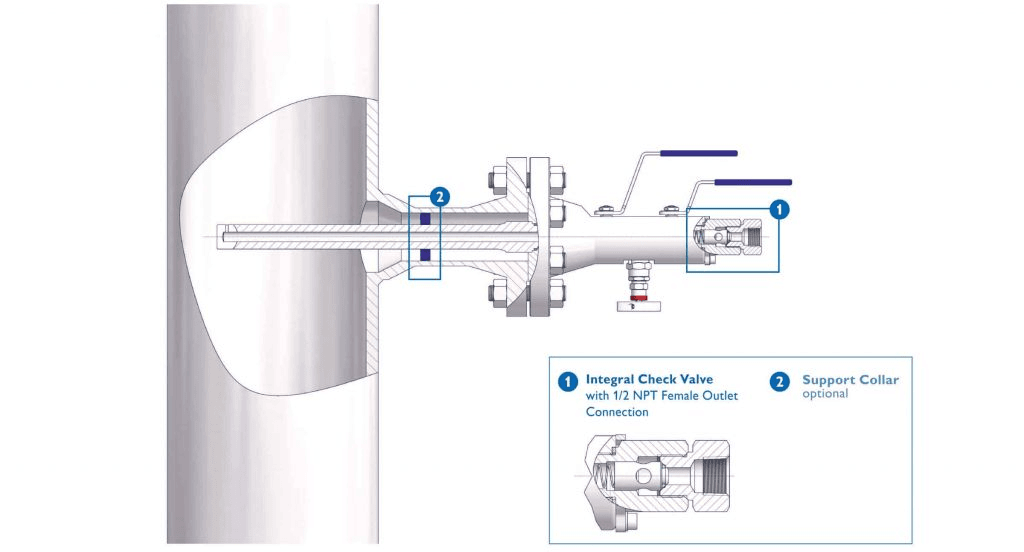

Safety and Sealing Features

Safety and integrity are paramount in the design of the EMT Chemical Injection Quill:

- High-Pressure Seals: The quill is equipped with high-pressure seals that prevent any leakage of chemicals back along the quill shaft, ensuring that all chemicals are delivered into the flow stream.

- Pressure Containment: Designed to withstand the high pressures of industrial pipelines, the quill’s structure prevents any breach that could lead to chemical exposure or environmental contamination.

- Check Valves: To prevent the backflow of the process fluid into the chemical supply. These valves ensure that operations remain safe even under varying pressure conditions.

4. Applications

Oil and Gas

- Corrosion and Scale Prevention: The quill injects inhibitors and scale preventatives to protect pipeline walls and equipment from corrosion and scale buildup. Which are common in the oil and gas industry.

- Benefits: Regular injection of these chemicals extends the lifespan of infrastructure and ensures uninterrupted flow of oil and gas, reducing maintenance costs and preventing costly shutdowns.

Water Treatment

- Disinfection and Chemical Dosing: In water treatment facilities, the quill is to inject chlorine, chloramines, and other disinfectants to eliminate pathogens from the water supply.

- Roles: It ensures that the chemicals are well mixed with the water before it is distributed. It provides safe drinking water and meeting regulatory standards.

Chemical Processing

- Controlled Addition of Reactants: The quill allows for the precise addition of reactants in chemical reactors, crucial for maintaining the desired chemical reactions and product quality.

- Importance: This precision avoids wastage of materials and ensures that the end products are consistent in quality and characteristics.

5. Benefits

Improved System Efficiency

- Precise Dosing: Accurate chemical dosing ensures optimal reactions and process outcomes, enhancing the overall efficiency of the system.

- Better Resource Utilization: Efficient chemical use reduces waste and improves the cost-effectiveness of operations.

Reduced Maintenance Costs

- Easy Maintenance and Retractability: The quill’s design allows for easy access and maintenance without the need for full system shutdowns. This retractability significantly reduces operational downtimes and associated costs.

- Longevity: Durable materials and effective seals extend the maintenance intervals and life span of the quill.

Enhanced Safety

- Minimized Chemical Exposure: The sealed and contained design minimizes the risk of chemical exposure to workers, enhancing workplace safety.

- System Integrity: Reliable operation and robust construction reduce the risk of system failures and accidents.