Description

The Fast, Safe, and Secure Solution for Oil & Gas Pipeline Access

In the high-pressure, zero-tolerance world of oil and gas pipelines, accessing termination points for pigging, inspection, maintenance, or connection demands technology that prioritizes speed, safety, and absolute reliability. Traditional bolted closures are slow, hazardous, and costly. EMT Clamp Ring Closures represent the cutting-edge solution, delivering unmatched operational efficiency and enhanced safety for critical pipeline access points.

What is a Clamp Ring Closure?

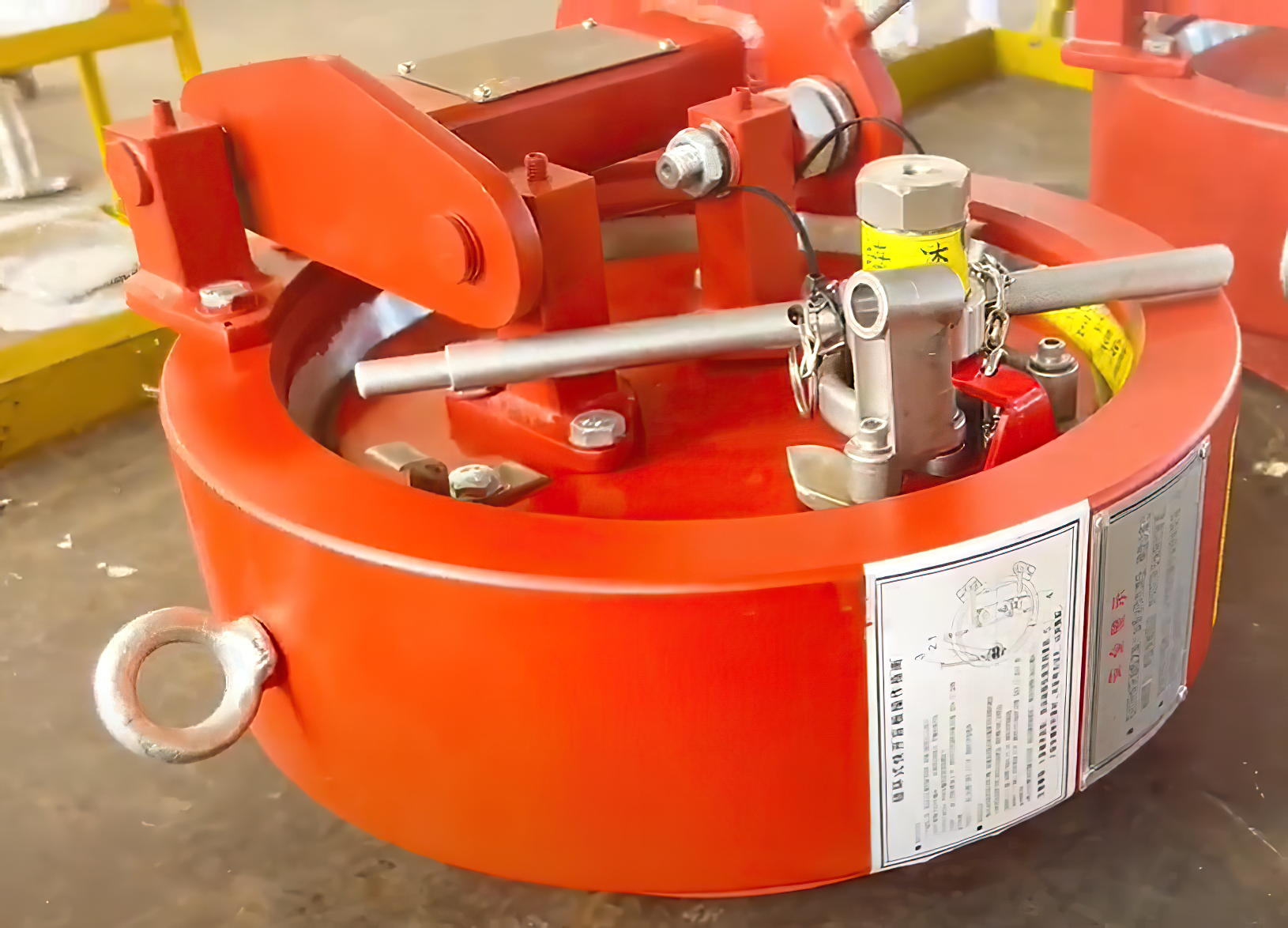

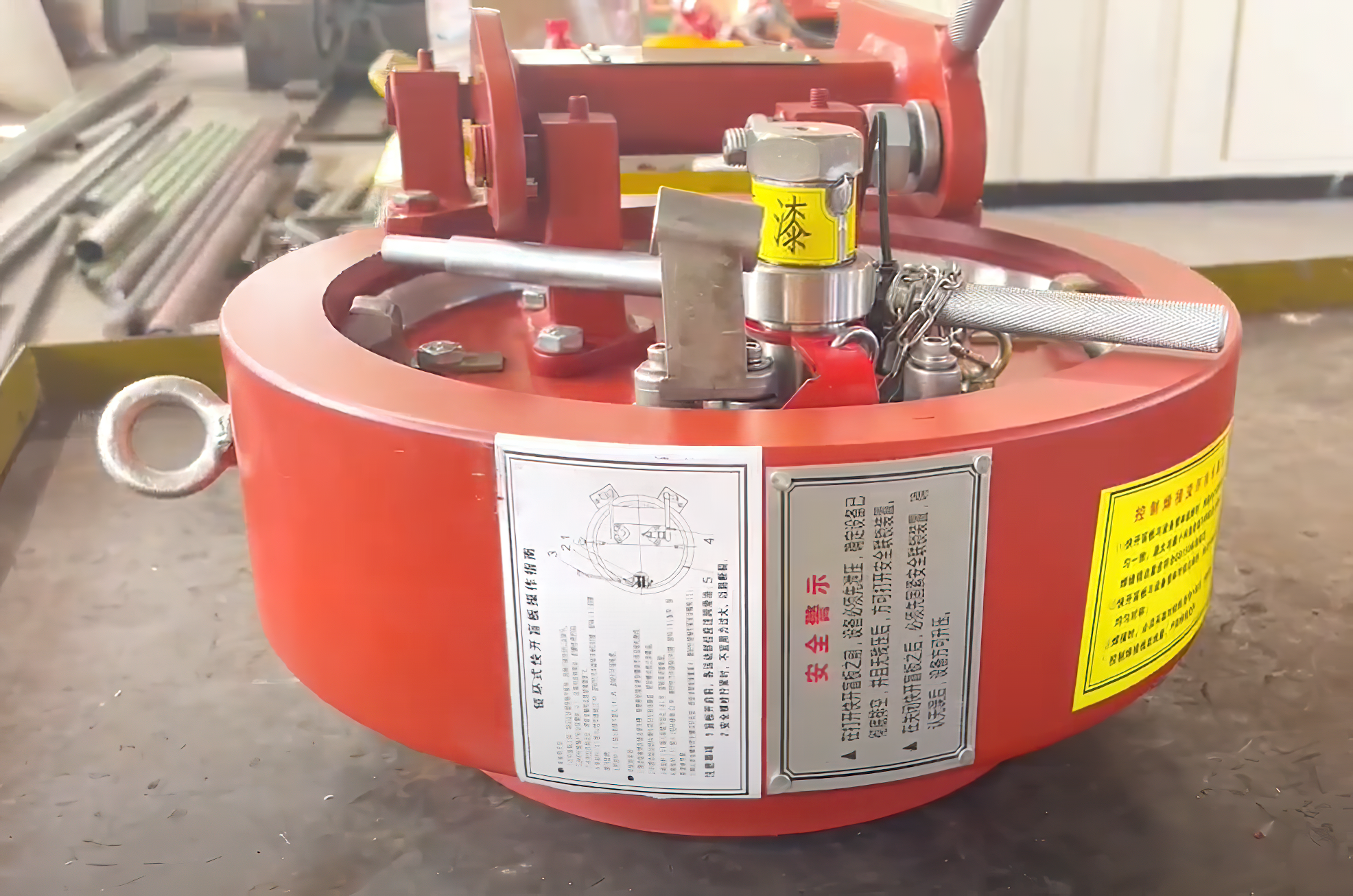

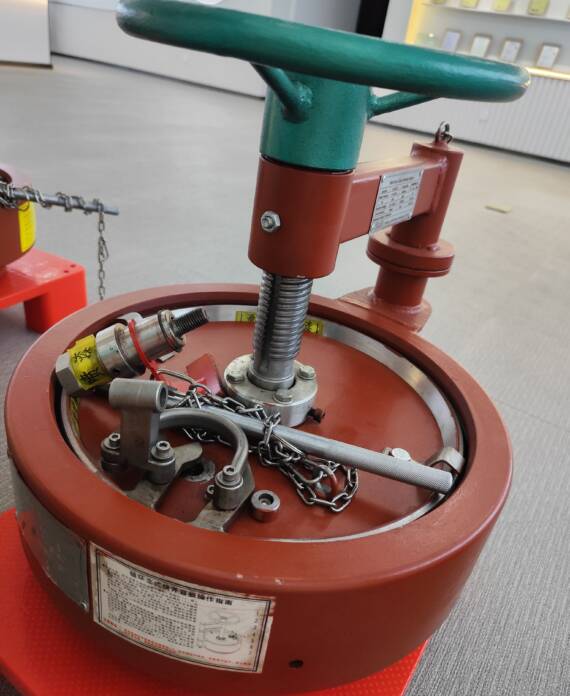

A Clamp Ring Closure is a sophisticated, engineered mechanism designed to rapidly and securely seal the end of a pressure vessel or pipeline. It replaces the cumbersome, time-consuming process of bolting with a robust, integrated system. Its core components are:

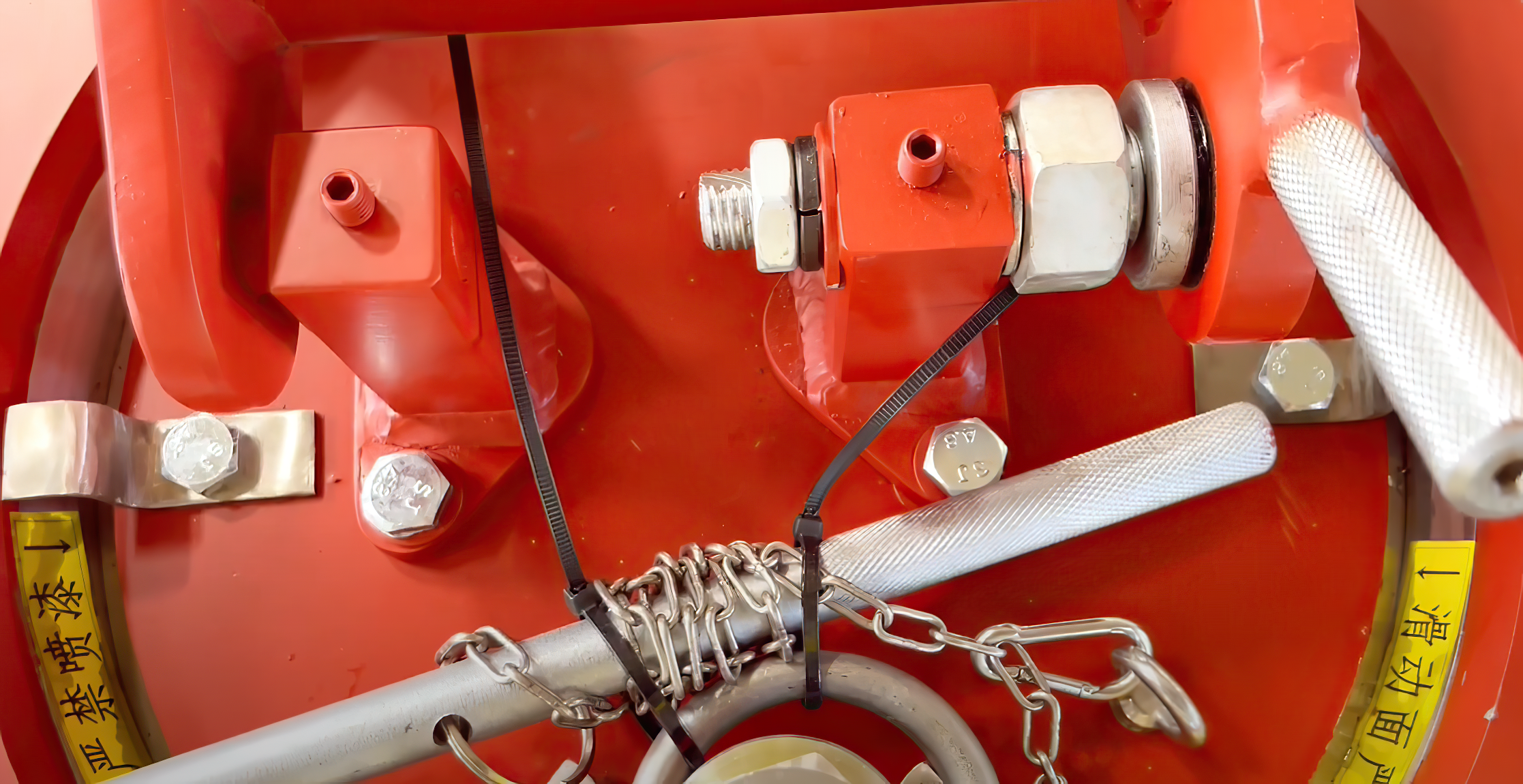

The Heavy-Duty Clamp Ring: A precision-machined, split ring that encircles the pipeline flange and cover plate interface.

Integrated Hinge & Locking Mechanism: A sturdy hinge allows one side of the ring to swing open. The opposite side features a powerful, reliable lock (hydraulic, manual toggle, or screw latch) ensuring positive closure.

High-Pressure Seal: A specialized seal (O-ring, profile gasket) seated between the pipeline flange face and the cover plate, activated by system pressure for ultimate integrity.

Simple Operation: Release the lock, swing the clamp ring clear, and remove the cover plate – access is achieved in minutes. Reverse the process to achieve a secure, pressure-tight seal – no loose bolts required.

Key Advantages of Clamp Ring Closures:

Revolutionary Speed & Reduced Downtime: Forget hours of bolting. Clamp Ring Closures enable opening or closing in minutes. This drastic reduction in access time translates directly into maximized operational uptime and significant cost savings during pigging runs, inspections, filter changes, and maintenance activities.

Uncompromising Safety Design: Engineered to eliminate critical hazards:

Eliminates Loose Parts: Removes the inherent risk of dropped bolts, nuts, or tools – a major cause of worksite incidents.

Positive, Verifiable Locking: The robust locking mechanism provides clear visual and physical confirmation of a secure closure. Operators remain safely outside the swing path.

Reduced Manual Handling: Minimizes strenuous physical effort and potential for worker strain or injury associated with heavy bolting.

Superior Pressure Containment & Seal Reliability: The clamp ring design applies massive, uniform sealing force around the entire circumference. This ensures leak-free performance under extreme pipeline pressures, temperature variations, and cyclic loading – critical for environmental protection and operational safety.

Operational Simplicity & Efficiency: Typically requires only 1-2 operators, reducing labor requirements and costs. The intuitive open/close action requires less specialized training than complex bolting sequences.

Durability & Lower Maintenance: Built with fewer moving parts than traditional bolted assemblies and constructed from robust materials for harsh environments, Clamp Ring Closures offer exceptional longevity and reduced lifecycle maintenance costs.

Essential Oil & Gas Applications for Clamp Ring Closures:

Clamp Ring Closures are the preferred technology wherever rapid, safe, and secure access to pipeline or vessel ends is paramount:

Pig Launchers & Receivers: Enabling swift insertion and retrieval of inspection, cleaning, or batching pigs.

Filter & Strainer Housings: Providing quick access for element cleaning or replacement.

Tank Inlet/Outlet Connections: Facilitating efficient connection and disconnection.

Maintenance Bypass Lines: Allowing rapid setup of temporary flow paths.

Test Points, Vents & Drains: Securing access points requiring regular monitoring or intervention.

Pipeline Termination Points & Future Tie-Ins: Essential for commissioning and connection.

Selecting the Right Clamp Ring Closure:

Ensure optimal performance and safety by choosing Clamp Ring Closures that meet these critical criteria:

Compliance & Certification: Manufactured to stringent international standards (ASME B16.47, API 6D, ISO, PED) with relevant certifications for pressure equipment.

Pressure & Temperature Rating: Specifically engineered for your pipeline’s Maximum Allowable Working Pressure (MAWP) and full operating temperature range.

Material Integrity: Constructed from suitable materials (carbon steel, stainless steel, corrosion-resistant alloys) compatible with the product and environment.

Seal Performance: Features seals specifically engineered for the product type, pressure, temperature, and potential contaminants.

Locking Mechanism Reliability: Prioritize robust, field-proven locking systems designed for ease of operation, positive engagement, and long-term durability.

Proven Manufacturer: Source from an established manufacturer with expertise in engineering, precision manufacturing, and ongoing support for critical pipeline safety components.

Conclusion

Secure Your Pipeline Access with Clamp Ring Closure Technology

For oil and gas operators demanding maximum safety, operational efficiency, and minimal downtime at pipeline termination points and access locations, Clamp Ring Closures are the definitive solution. This advanced technology replaces outdated, hazardous bolting with a fast, inherently safer, and highly reliable clamping mechanism. The result is measurable: enhanced protection for personnel, greater security for the environment, and significant optimization of operational costs. Upgrade your critical access points – implement the speed, security, and reliability of Clamp Ring Closures today.