Description

Corrosion Coupon Assembly Introduction

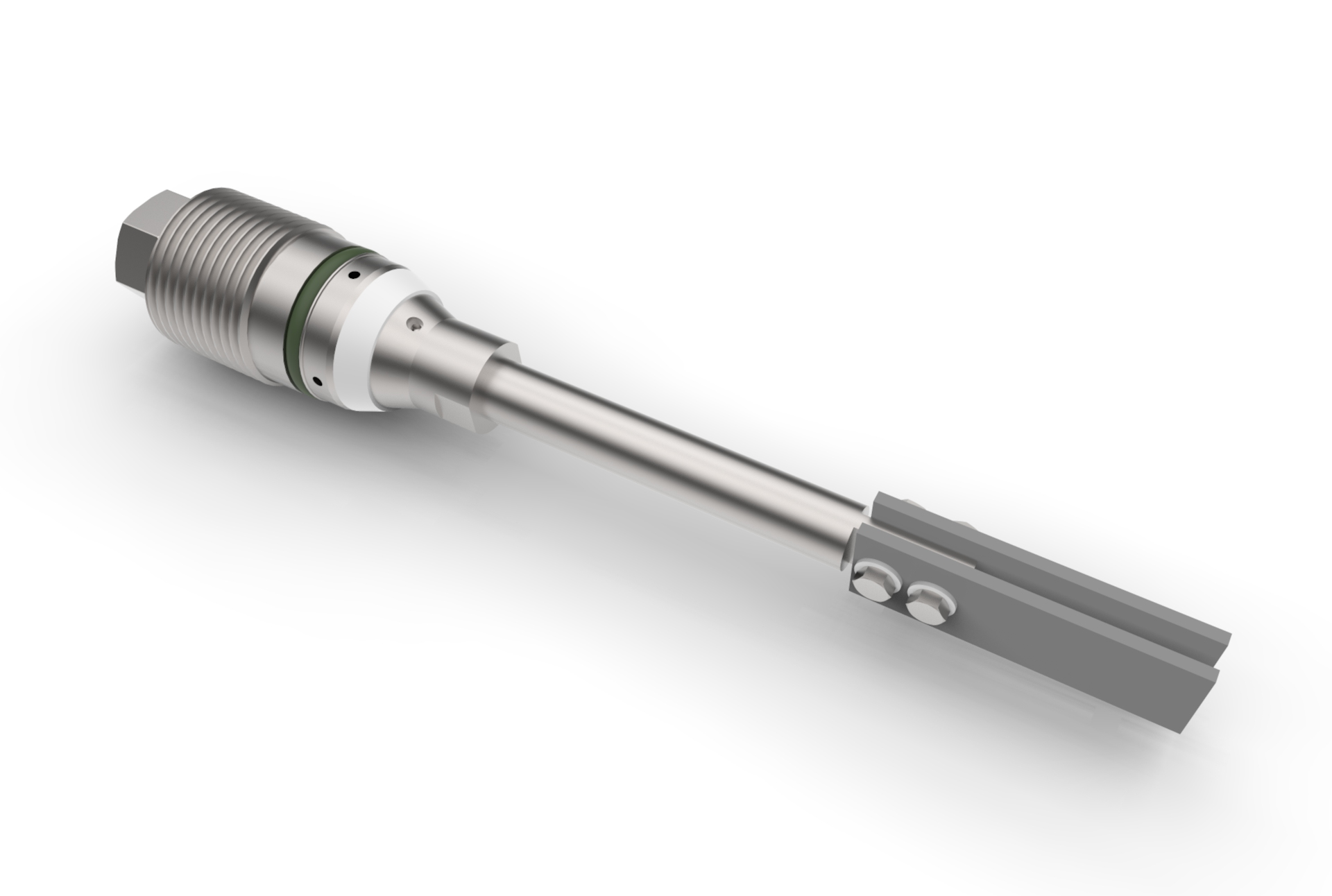

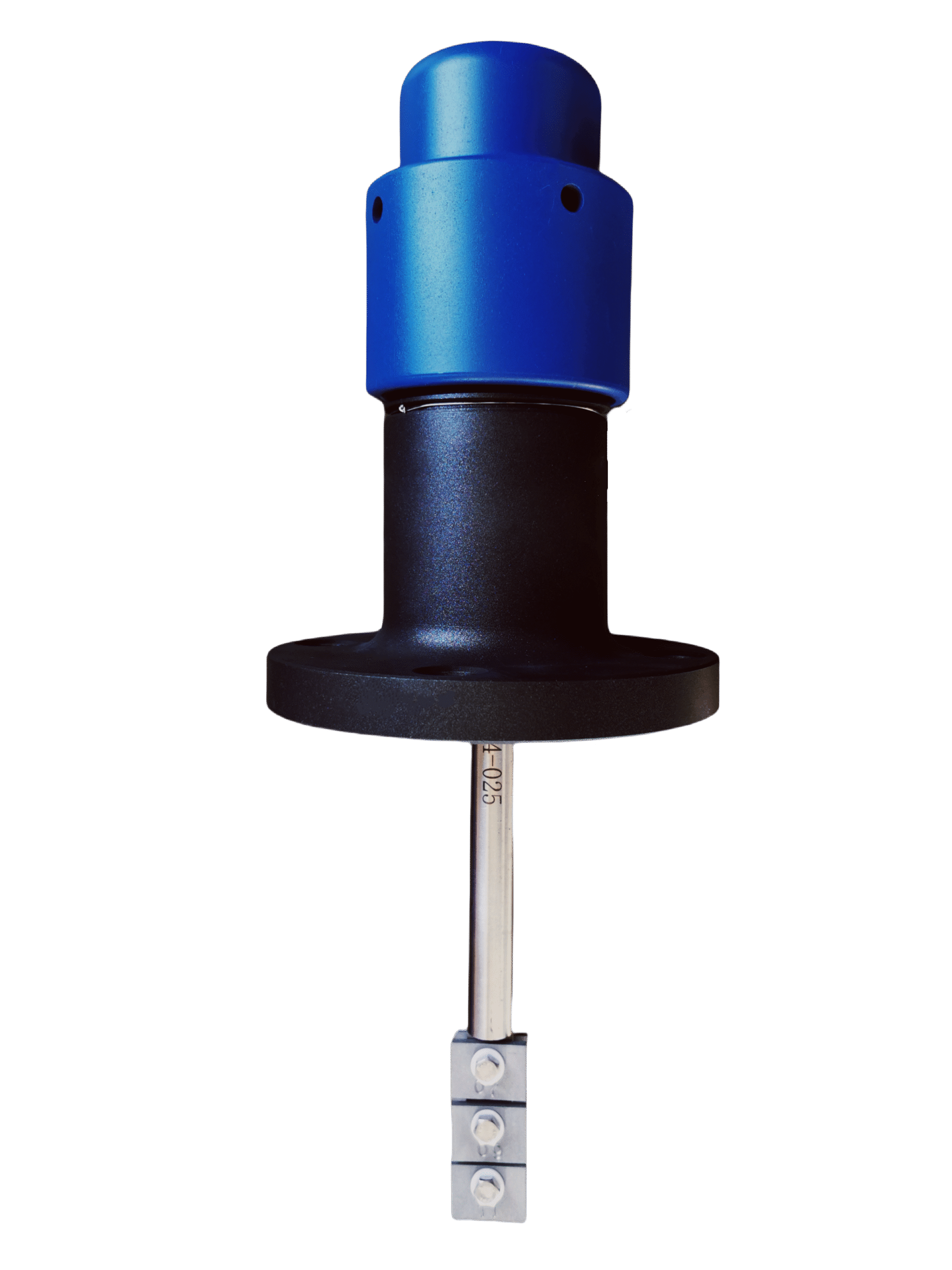

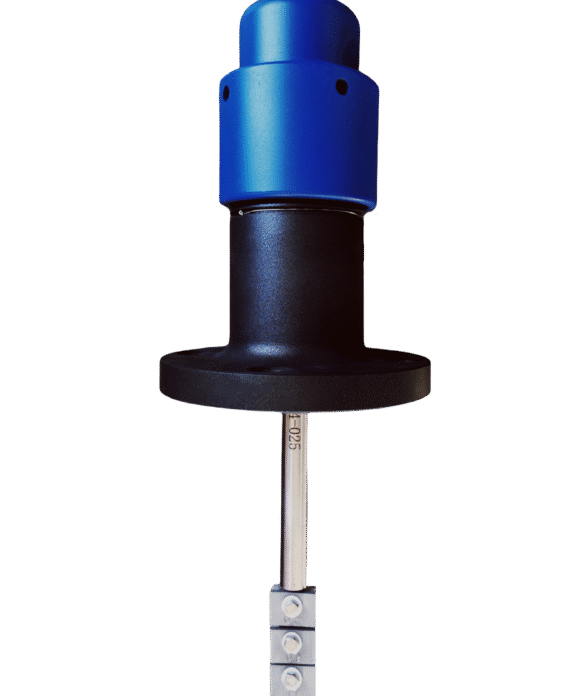

A corrosion coupon assembly is a critical component in monitoring pipeline corrosion rates. It typically consists of a metal strip or specimen that mimics the pipeline material. Operators insert these coupons into the pipeline’s flow. Over time, they expose the coupons to the same conditions as the pipeline. After a set period, they retrieve and analyze the coupons to assess corrosion levels. This process allows for accurate measurement of material loss and corrosion rate. Moreover, it helps in predicting the pipeline’s lifespan.

Operators can make informed decisions on maintenance and replacements based on these insights. Thus, corrosion coupon assemblies are essential for maintaining pipeline integrity and safety. Additionally, their use helps in optimizing operational costs by preventing over-maintenance and early failures. Their simple yet effective functionality makes them a staple in industries reliant on pipelines, such as oil and gas. Overall, these assemblies provide invaluable data, enhancing operational efficiency and safety standards.

Corrosion Coupon Types (Corrosion Coupon Assembly)

| Name | Strip Coupon | Multihole Strip Coupon | Disc Coupon |

| Applications | Commonly used for most evaluations. | Use with low-pressure access equipment or through narrow ports that a standard 3/4 inch wide coupon cannot pass. | These circular coupons work in multiple disc monitoring applications. |

| Size | 3”*3/4”*1/16” (76.2mm*19.0mm*3.2mm) |

3”*1/2”*1/16” (76.2mm*12.7mm*3.2) With mounting holes |

Φ1.25”(31.8mm)Thickness 1/16”(3.2mm) |

Corrosion can be categorized into three main types

General Corrosion

General corrosion, commonly known as uniform corrosion, occurs evenly across a large area of a pipeline. This type is the least hazardous because it’s predictable and consistent, making it easier to manage.

Local Corrosion

Local corrosion, also referred to as localized or non-uniform corrosion, poses a greater risk than uniform corrosion. It is more challenging to detect and prevent because it does not occur evenly. Localized corrosion can cause sudden and unexpected damage to metal components, potentially leading to severe accidents, including fires or personal injuries.

Stress Corrosion

Stress corrosion cracking happens when metal materials fail due to the combined effects of tensile stress and a corrosive environment. The onset of stress corrosion can vary; some metals may crack within days, while others might take years. This variability indicates that stress corrosion often has a variable incubation period. Typically, stress corrosion cracks develop dendritically, branching out perpendicular to the direction of the tensile stress.

Why Choose Us?

Why choose us? We prioritize customer satisfaction by offering samples first, allowing you to verify the quality of our products and services. Additionally, we boast the fastest delivery times in the industry, ensuring you receive your orders promptly. To further support your needs, our dedicated team is available 24 hours a day, 7 days a week. This round-the-clock service guarantees that we are always here to assist you, whatever your requirements may be. Choose us for reliability, speed, and continuous support.