Description

Introduction of Corrosion Coupons

Corrosion Coupon Oil and Gas are small, standardized samples of metal that are installed within a pipeline system to measure the rate and type of corrosion over time. By analyzing the degradation of these coupons after exposure to operational conditions, maintenance teams can predict the overall corrosion behavior of the pipeline. Also enabling timely interventions and maintenance to prevent failures.

Product Attributes

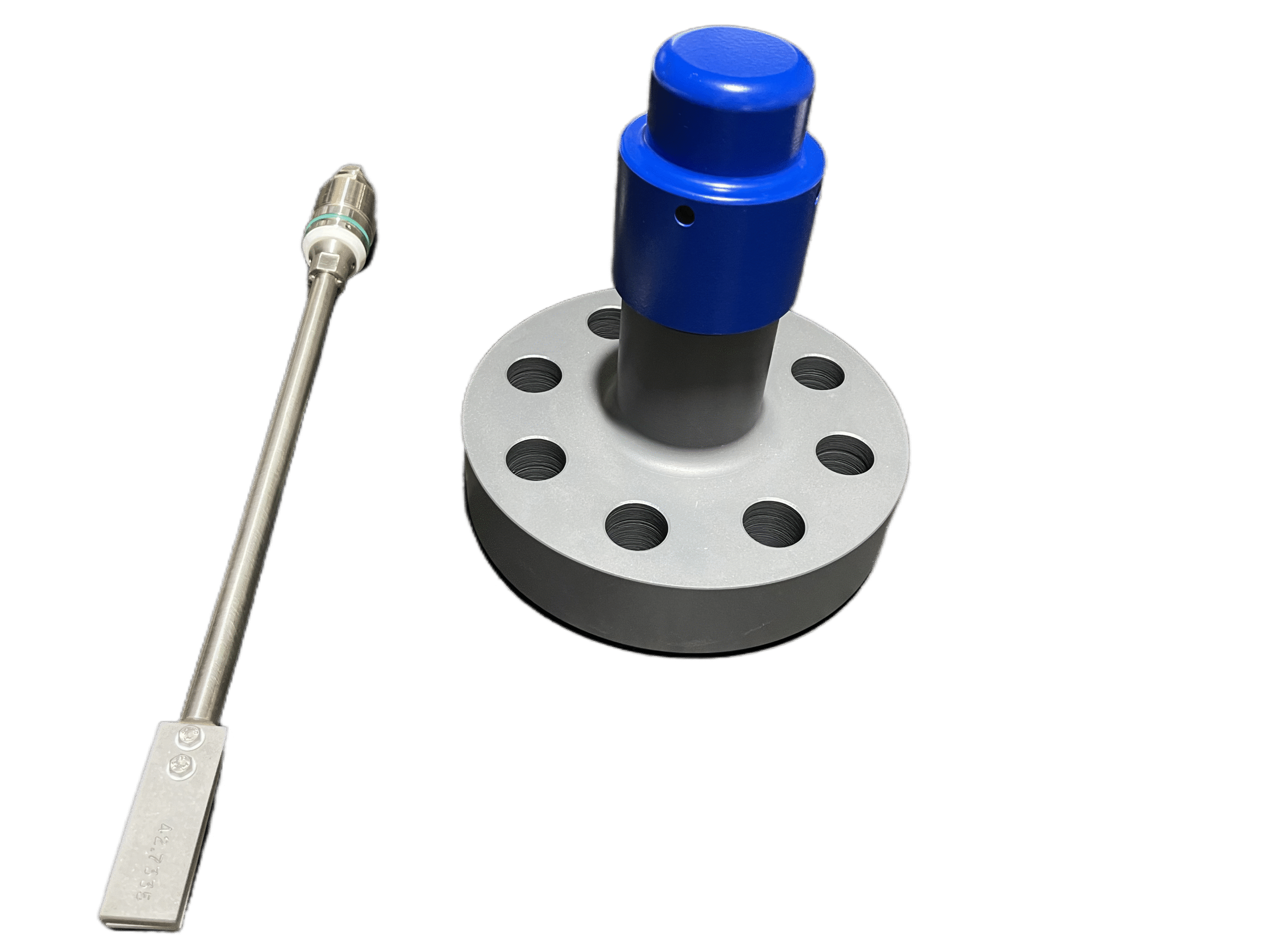

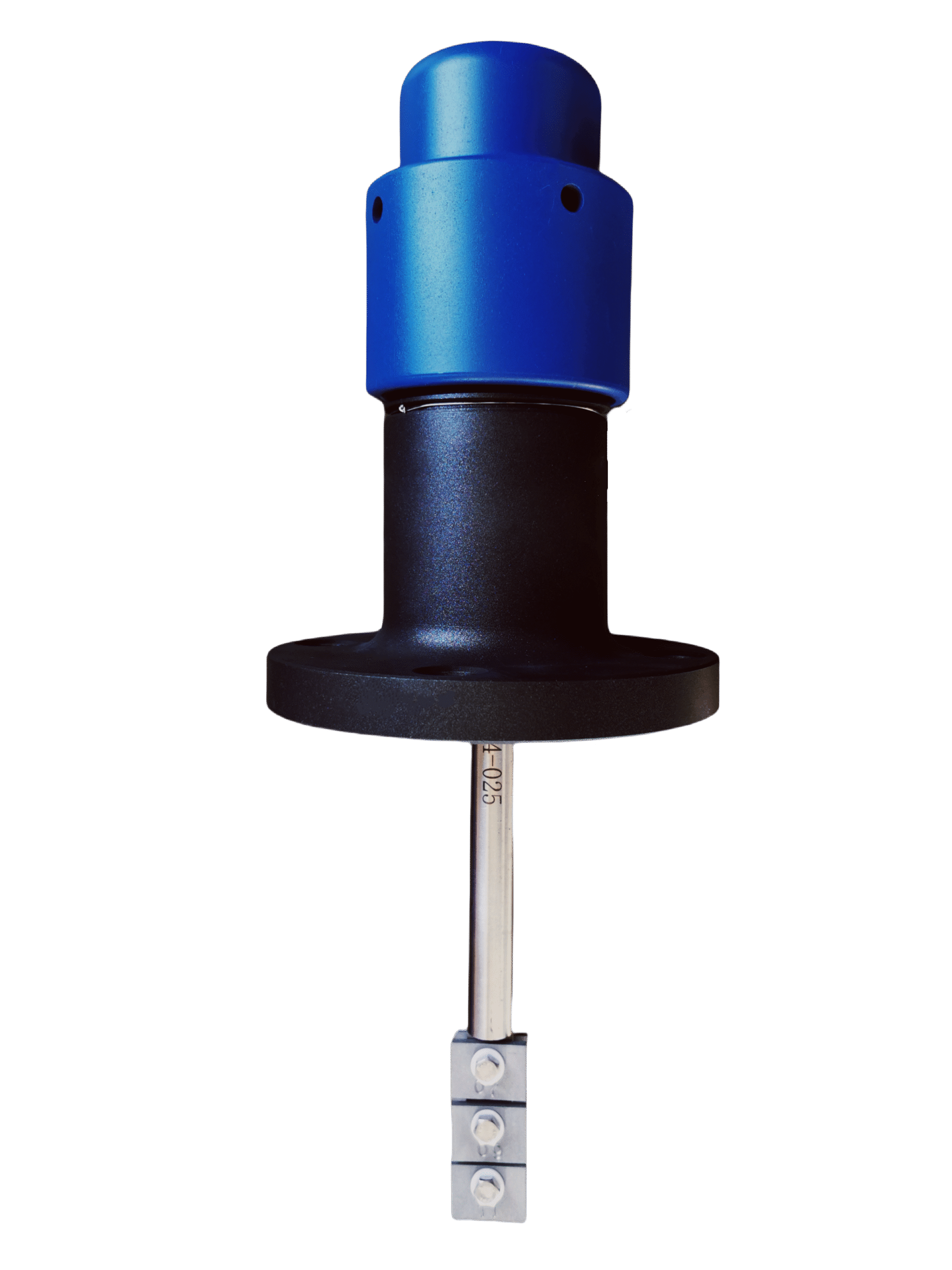

- Product Name: EMT Corrosion Coupon

- Brand Name: EMT Pigging

- Condition: New

- Application: Corrosion Test

- Size: 3″ x 3/4″ x 1/16″

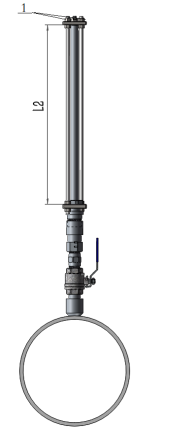

- Design Temperature: -20℃ to +200℃

- Design Pressure: 150LB to 1500LB

- Material: Stainless Steel

- Features: High Accuracy, Low Cost

- Minimum Order Quantity (MOQ): 1 Set

- Certification: ISO9001

Additional Information

- Place of Origin: Liaoning, China

- Weight (KG): 0.02

![]()

Industry Applications of Corrosion Coupon

1. Oil & Gas Pipeline

EMT Corrosion Coupon Oil and Gas are particularly crucial in the oil and gas industry due to the highly corrosive nature of the environments in which pipelines operate. In this sector, pipelines are often exposed to a variety of corrosive agents:

- Hydrogen Sulfide (H2S): Often present in crude oil and natural gas, H2S is a highly corrosive gas. Especially under high pressure and temperature conditions, leading to sulfide stress cracking.

- Carbon Dioxide (CO2): CO2 can combine with water to form carbonic acid, which is mildly corrosive to steel and can significantly degrade pipeline integrity over time.

- Water Content: The presence of water, especially saltwater, can lead to corrosion processes such as pitting and galvanic corrosion.

- Microbial Activity: Microbial induced corrosion (MIC) can also occur in pipelines where bacteria produce corrosive by-products, attacking pipeline materials.

EMT corrosion coupons are designed to emulate the pipeline material, allowing them to accurately measure the rate of corrosion and thus help in determining the necessary frequency and type of maintenance required. Regular analysis of these coupons helps predict potential failure points and schedule appropriate interventions, such as pipeline cleaning, coating repair, or the application of corrosion inhibitors.

2. Pipeline Pigging

During pipeline pigging operations, EMT corrosion coupons play a pivotal role in maintaining the health of the pipeline:

- Routine Maintenance Checks: Integrated within pigging operations, corrosion coupons can travel with the pig, exposed to the same conditions as the pipeline. This provides a direct measure of the corrosive elements in different sections of the pipeline.

- Effectiveness of Corrosion Inhibitors: Corrosion coupons are used to evaluate the effectiveness of corrosion inhibitors that are applied during pigging operations. By comparing the corrosion rate on coupons from sections treated with inhibitors versus untreated sections, operators can assess and adjust the inhibitor dosage and composition.

- Data Collection for Analysis: The coupons collect data that can be analyzed to provide insights into the conditions within the pipeline, helping to refine predictive maintenance schedules and improve the overall strategy for pipeline integrity management.

Packaging and Delivery Details

- Selling Units: Single item

- Package Size: 6x6x10 cm

- Gross Weight: 1.000 kg

- Quality Assurance and Warranty:

- Video Outgoing-Inspection: Provided

- Machinery Test Report: Provided

- Warranty: 1 Year

Benefits of Using Corrosion Coupon in Oil and Gas Pipelines

1. Cost-Effective Monitoring

Corrosion coupons provide a highly economical solution for monitoring corrosion rates in pipelines. Here’s how:

- Lower Initial Investment: Unlike sophisticated electronic corrosion monitoring systems, corrosion coupons require minimal initial investment. This makes them accessible even for smaller operations or projects with limited budgets.

- Reduced Maintenance Costs: By providing precise corrosion rate data, these coupons help optimize maintenance schedules, thereby avoiding unnecessary inspections and reducing the frequency of costly repairs and downtime.

2. Easy to Install and Retrieve

The design and implementation of corrosion coupons are tailored for simplicity:

- Standardized Dimensions: The uniform size of the coupons ensures they fit a variety of pipeline dimensions and can be easily handled by technicians.

- Safety and Accessibility: The process is designed to minimize risk to maintenance personnel and can be performed under a variety of environmental conditions, ensuring consistent monitoring.

3. Accurate Corrosion Rate Measurement

The specificity and reliability of corrosion coupon data are vital for effective pipeline management:

- Direct Measurement: By physically measuring the weight loss in the coupon after exposure, operators obtain direct empirical data on the material loss rate, which is more reliable than indirect methods.

- Material Specificity: Coupons can be made from the same material as the pipeline, or from multiple materials found within the pipeline system, providing specific insights into different corrosion behaviors under identical operational conditions.

- Historical Data Comparison: Regular retrieval and analysis of cCorrosion Coupon Oil and Gas help build a historical database of corrosion rates. Which can be crucial for trend analysis and predictive maintenance planning.

4. Compliance and Safety

Regular use of Corrosion Coupon Oil and Gas plays a critical role in regulatory compliance and safety assurance:

- Regulatory Compliance: Many industry regulations require documented monitoring of pipeline integrity. Corrosion coupons provide a straightforward means to comply with these regulations.

- Early Detection: The early detection of increased corrosion rates can signal the need for immediate maintenance actions, thereby preventing leaks or bursts that could lead to environmental damage and personal injury.

- Safety Record Improvement: Consistent monitoring and maintenance based on corrosion data help improve the overall safety records of pipeline operations, a critical factor for industry reputation and regulatory approval.

5. Customizable Options

EMT’s Corrosion Coupon Oil and Gas are highly adaptable to meet diverse operational needs:

- Variety of Sizes and Pressures: Depending on the pipeline pressure ratings and diameters, so coupons are available in different sizes and are designed to withstand varying pressures.

- Material Variants: Coupons can be fabricated from a range of materials that are used in the pipeline. It includes carbon steel, stainless steel, and more specialized alloys, to match the specific corrosion challenges of each pipeline environment.

- Application-Specific Designs: For special applications. Such as high-sulfur environments or high-flow areas, coupons can be customized to provide the most relevant data.