Description

Corrosion probes and coupons are essential tools for monitoring and assessing corrosion in various industrial environments, particularly in high-pressure systems. One notable model is the EMT-EP100, a fixed-length, retrievable electrical resistance corrosion probe designed for use in demanding conditions.

1. Order Information

Access Fitting Body of Corrosion Probes and Coupons

| Model | ||||||

| EMT-CIPA | Access Fitting Body of Corrosion Probes and Coupons | |||||

| – The material of Access Fitting Body | ||||||

| 0 | CS | |||||

| 1 | 316SS | |||||

| 2 | 316LSS | |||||

| 3 | DUPLEX SS | |||||

| The Type of Access Fitting Body | ||||||

| B | 2″Welded(suffix “pressure rating” can be added to B) | |||||

| F | 2″ANSI Flange(suffix “pressure rating & sealing type” can be added to F) | |||||

| -Tee Size- pressure rating & sealing type if flanged end | ||||||

| 0 | No Tee | |||||

| 1 | 1/4″NPT(F)Tee | |||||

| 2 | 1/2″NPT(F)Tee | |||||

| 3 | 3/4″NPT(F)Tee | |||||

| 4 | 1″NPT(F)Tee | |||||

| 5 | Hole for 1/4″SWN Flange | |||||

| 6 | Hole for 1/2″SWN Flange | |||||

| 7 | Hole for 3/4″SWN Flange | |||||

| 8 | Hole for 1″SWN Flange | |||||

| -Protective Cover Type/ Material | ||||||

| 0 | No Protective Cover | Material | ||||

| 1 | Without hole | CS or 0 | ||||

| 2 | With hole | SS or 1 | ||||

| 3 | Bleed Valve | DSS or 3 | ||||

| 4 | Bleed Valve, & Pressure Gauge | |||||

| For Example:EMT-CIPA-0F600#RF-0-2/CS shows 2″ANSI 600#RF Flange Access Fitting Body in CS, no Tee, Protective Cover in CS with hole

0F600#RF: 0F_ Access Fitting Body is Flanged in CS , 600#RF _Size is 2″ANSI 600#RF , 0:No Tee 2: Protective cover with 1/2NPT(F) hole /CS: Protective cove material in CS |

||||||

Cylindrical Electrical Resistance Corrosion Probe

| Model | |||||||||||

| EP100 | Cylindrical Electrical Resistance Corrosion Probe | ||||||||||

| -Code | Body Material | ||||||||||

| -B | 1 | 316 SS | |||||||||

| 2 | 316L SS | ||||||||||

| 3 | DUPLEX SS | ||||||||||

| 4 | INCONEL | ||||||||||

| -Code | Connector Type | ||||||||||

| -C | 1 | Standard connector | |||||||||

| 2 | Meet user requirements connector | ||||||||||

| -Code | ER Element Useful Thickness Options | ||||||||||

| -T | 10 | 10 mil thickness (5 mil useful probe life) | |||||||||

| 20 | 20 mil thickness (10 mil useful probe life) | ||||||||||

| 50 | 50 mil thickness (25 mil useful probe life) | ||||||||||

| Code | ER Probe Shield Options | ||||||||||

| -S | 0 | No shield DUPLEX SS INCONEL | |||||||||

| 1 | Standard shield | ||||||||||

| 2 | Hi-velocity shield | ||||||||||

| Code | Element Alloy Material | ||||||||||

| -xxx | Code | Probe Characteristic Length | |||||||||

| -xxx | mm | ||||||||||

| For Example:EP100-B1-C1-T20-S0-A105-358 EP100 : Cylindrical Electrical Resistance Corrosion Probe B1: Body Material is 316SS C1: Connector Type: Standard connector T20: ER Element is 20 mil thickness (10 mil useful probe life) S0: No shield A105: Element Alloy Material is A105 358:Probe length is 358mm |

|||||||||||

Corrosion Coupons

| Model | |||||||||||||

| CC | Corrosion Coupons | ||||||||||||

| -Code | Plug Body Assembly | ||||||||||||

| Pxxx | Type | Material | Sealing Material | ||||||||||

| 0 | No Request | 0 | CS | 0 | No Request | ||||||||

| 1 | Hollow Plug Body | 1 | 316SS | 1 | Viton O-Ring / PTFE Primary Packing | ||||||||

| 2 | Solid Plug Body | 2 | 316LSS | 2 | HNBR | ||||||||

| 3 | DUPLEX SS | ||||||||||||

| 4 | INCONEL | ||||||||||||

| Type of Coupon Holder | |||||||||||||

| SR | Fixed Coupon Holder for assembling rectangular coupon | ||||||||||||

| AR | Adjustable Coupon Holder for assembling rectangular coupon | ||||||||||||

| LR | Ladder Coupon Holder for assembling rectangular coupon | ||||||||||||

| SC | Fixed Coupon Holder for assembling circular coupon | ||||||||||||

| AC | Adjustable Coupon Holder for assembling circular coupon | ||||||||||||

| -Pipe Size | |||||||||||||

| x | Pipe Size in inch | ||||||||||||

| – Coupon Size | |||||||||||||

| A×B×C | Coupon Size in inch or mm | ||||||||||||

| – Coupon Material | |||||||||||||

| x | Grade | ||||||||||||

| -Finishing of Coupon | |||||||||||||

| 0 | Mill | ||||||||||||

| 1 | Glass Bead | ||||||||||||

| – Isolation Gasket | |||||||||||||

| 0 | No Gasket | ||||||||||||

| 1 | Nylon Gasket | ||||||||||||

| 2 | FTFE Gasket | ||||||||||||

| For Example:CC-P221-SR-6″-3″×1/2″×1/8″-MS1018-0-2 CC: Corrosion Coupons

P221: Solid Plug Body in 316LSS Viton O-Ring and PTFE Primary Packing SR-6″:Fixed Coupon Holder for assembling rectangular coupon and for 6″pipe 3″×1/2″×1/8″: Coupon Size MS1018: Coupon Material 0: Finishing of Coupon is Mill 2: Material of Isolation Gasket is PTFE |

|||||||||||||

Example for a set of Corrosion Coupons Assembly:

EMT-CIPA-0F600#RF-0-1+ CC-P221-SR-6″-3″×1/2″×1/8″-MS1018-0-2

2. Description of Corrosion Probes and Coupons

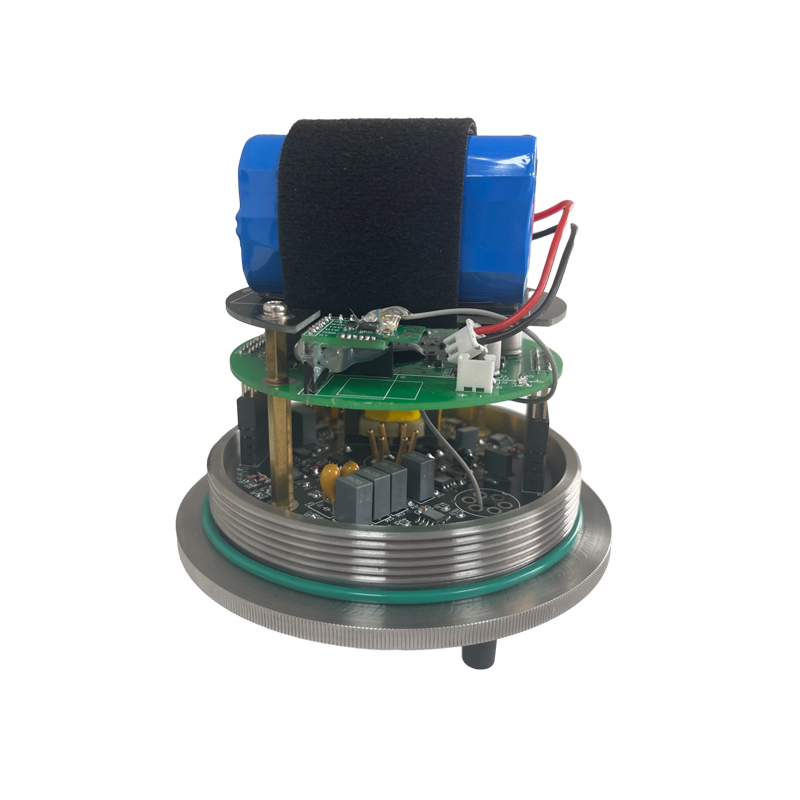

The EMT-EP100 probe features a fully welded structure, making it highly suitable for harsh environments. Its robust design includes:

- Extension Rod with Sensing Element. The probe assembly consists of an extension rod that houses a sensing element, allowing for precise corrosion measurement.

- Threaded Connecting Seat. This facilitates secure installation and retrieval of the probe.

- Welded and Sealed Components. You weld and seal each part of the probe assembly to ensure durability. You further protect the interface end with high-temperature glass sintering, which enhances its resistance to extreme conditions.

- Protective Cap. The probe sensor can be equipped with a protective cap to safeguard it during installation and operation.

1) Installation and Retrieval

Key features include:

- Hollow Plug Connection. The probe is installed into a hollow plug using a probe nut and sealing ring, ensuring a secure fit.

- Retrieval Tool and Service Valve. The probe-plug assembly can be efficiently installed or retrieved using a dedicated retrieval tool and service valve, facilitating maintenance while keeping operations running smoothly.

2) Specifications

Materials

You can construct the probe body from various materials, including 316 stainless steel, 316L stainless steel, duplex stainless steel (DSS), and INCONEL. This variety ensures compatibility with different media.

Temperature Rating

The probe operates effectively within a temperature range of -200℃ to 260℃, with an optional range extending from 260℃ to 450℃.

Pressure Rating

This probe handles pressures less than 45 MPa, making it suitable for high-pressure applications.

Leak Prevention

To prevent media leakage, the design integrates the measuring element with the probe body through welding. The probe rod contains a heat and pressure-resistant filler, and the interface is sealed with glass. This combination ensures reliable performance in challenging environments.