Description

The EMT Cup Pig Pipeline system, with its cutting-edge design and comprehensive functionality, exemplifies a major leap forward in the field of pipeline maintenance technology. This system is explicitly engineered to cater to the complex and demanding requirements of contemporary industrial pipelines, ensuring optimal operational integrity, efficiency, and safety.

The EMT Cup Pig Pipeline system stands out as a landmark innovation in the realm of pipeline maintenance, incorporating state-of-the-art design features and multifunctional capabilities that address the evolving challenges faced by the industry today. Designed to meet the intricate and stringent demands of modern pipelines, this system facilitates enhanced performance, safety, and reliability across various operational contexts.

Innovative Design and Robust Construction

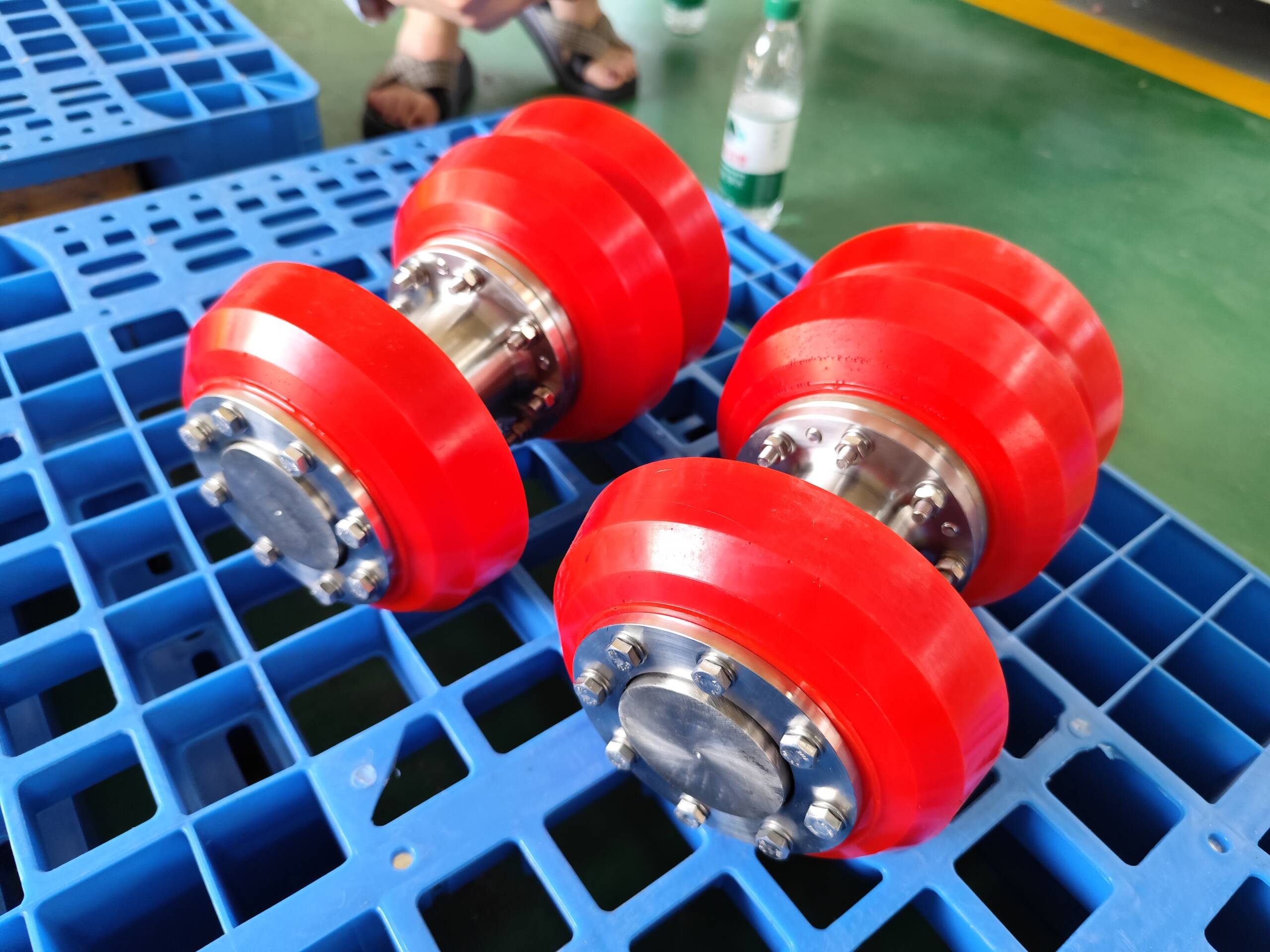

EMT’s Cup Pig has a good engineering to provide superior cleaning performance across pipeline systems ranging from 2 inches to 60 inches in diameter. Weighing only 4 kilograms, the Cup Pig is both lightweight and effective, capable of navigating through pipelines with a maximum running distance of about 100 kilometers. This capability is essential for extensive pipeline networks typically found in oil and gas applications.

Material and Construction

The body of the Cup Pig is constructed from high-quality polyurethane or fluorocarbon (FKM), materials chosen for their durability and chemical resistance. These materials ensure that the Cup Pig can withstand the harsh chemicals and environments typically associated with the oil and gas industry. The choice between carbon steel and stainless steel for the mandrel material allows for customization based on the specific needs of the pipeline environment, whether it requires resistance to corrosion or additional strength.

Design Features of EMT’s Cup Pig Pipeline

The Cup Pig features a four-cup design that ensures it maintains robust contact with the pipeline walls during operation, effectively removing dirt, debris, and deposits that can lead to blockages or corrosion. And then this design is crucial for maintaining the pipeline’s integrity and ensuring smooth flow of materials. Operating under a design temperature of up to 90°C and starting pressures between 0.2 and 0.3 MPa, the Cup Pig is versatile enough to handle a variety of operating conditions.

Technological Enhancements and Quality Assurance

EMT has integrated several technological enhancements that set the Cup Pig apart from traditional pipeline pigs.

Video Outgoing-Inspection

One of the most significant features is the inclusion of video outgoing-inspection capabilities, which provide real-time visual feedback of the pipeline’s internal condition. This feature allows for immediate assessment and decision-making, significantly reducing the risk of pipeline failures and enabling proactive maintenance.

Machinery Test Report

Each Cup Pig comes with a comprehensive machinery test report, ensuring that all equipment meets the stringent quality standards set forth by ISO9001 certification. This report serves as a testament to the reliability and performance of the Cup Pig before it work in the field.

Applications Across Industries of EMT’s Cup Pig Pipeline

The Cup Pig has a good design to serve a broad range of industries, including building material shops, construction works, energy, mining, and more specifically, oil and gas pipeline pigging.

Pipeline Pigging and Maintenance

In the context of pipeline pigging, the Cup Pig is an essential tool for cleaning and maintaining pipelines to prevent downtime and operational disruptions. Its ability to clear pipelines efficiently helps in maintaining the flow and quality of the materials being transported, whether it’s oil, gas, or other substances.

Drainage and Water Resistance

The Cup Pig is also effective in drainage applications, where water buildup can lead to significant issues. Its design allows for effective clearing of water and other liquids, ensuring that pipelines remain dry and functional.

Packaging, Delivery, and Warranty

Especially,EMT ensures that we will package securely each Cup Pig in a single package measuring 45x20x35 cm, with a gross weight of 8 kilograms. This packaging ensures that the product reaches its destination safely and is ready for immediate use.

A six-month warranty backs each Cup Pig, highlighting EMT’s confidence in its product’s reliability and performance. This warranty support is critical for users, ensuring that they can depend on the Cup Pig to perform as expected without the risk of early failure.

EMT’s Cup Pig Pipeline, Your Choice

As industries continue to evolve and as the demands on infrastructure grow, the need for reliable tools like the EMT Cup Pig Pipeline system becomes more pronounced. EMT’s commitment to innovation, quality, and customer satisfaction have obvious reflection in the Cup Pig, making it an indispensable tool in the maintenance of safe, efficient, and compliant industrial operations. The ongoing role of such tools will be critical not only in maintaining the health of pipeline systems but also in supporting the sustainable growth and efficiency of industries globally.

So EMT’s Cup Pig Pipeline system is a testament to the company’s innovation and commitment to quality in the pipeline maintenance sector. And then with its robust design, advanced technological features, and versatile applications, the Cup Pig is an invaluable tool for industries looking to maintain their pipeline systems efficiently and effectively. As pipelines continue to be a critical component of industrial operations, tools like the EMT Cup Pig will play a crucial role in ensuring their longevity and reliability.