Description

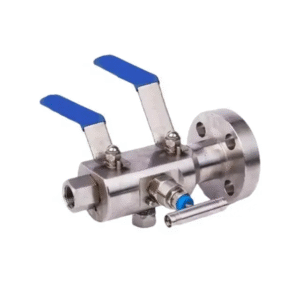

A Double Block and Bleed (DBB) valve is specifically designed to provide a high level of safety and efficiency within pipeline systems by incorporating two separate blocking valves and a single bleed valve into one unit. This configuration is crucial for isolating sections of a pipeline and securely venting any pressure or substances trapped between the two block valves. DBB valves are particularly valuable in critical industries like oil and gas, where preventing leaks and ensuring operational safety are paramount.

DBB valves are essentially double-barrier valves.

The fundamental operational principle of the DBB valve revolves around two sealing slides situated within the plug.

Closing the Valve:

To close the valve, begin by rotating the handwheel to turn the plug and the sealing slide by 90 degrees. Next, lower the plug and push the sealing slide toward the body cavity cover. This motion compresses the elastic sealing ring against the upper and lower ends of the valve bore, thereby creating a tight seal.

Opening the Valve:

To open the valve, start by rotating the handwheel to elevate the plug and retract the sealing slide away from the valve body’s sealing surfaces on both sides. After completely disengaging the slide plate from the sealing surfaces, continue to rotate the handwheel to turn the plug and the sealing slide by 90 degrees, which moves the valve into the open position.

Common Applications

DBB valves are extensively used in the oil and gas industry for various critical applications. These applications include isolating segments of pipelines for maintenance, safely venting pressures trapped between closed block valves, conducting leak detection through pressure assessments, facilitating the calibration of instruments without needing to shut down the system, and ensuring pipeline integrity by preventing contamination of the product. This enhances both safety and operational efficiency.

Safety Standards

Safety Standards for Using DBB Valves in Pipelines:

When employing DBB valves in pipeline systems, adhering to rigorous safety standards is crucial. These standards typically encompass:

Compliance with Industry Standards: It is essential to adhere to established API, ANSI, and ISO standards concerning valve design and performance testing.

Regular Maintenance and Inspection: Regular checks and maintenance of the valves are crucial to maintaining their performance and safe operation.

Proper Installation: Valves must be installed according to the manufacturer’s specifications to avoid leaks and ensure they function as intended.

Pressure Testing: Performing pressure tests is necessary to confirm the integrity of the valve seals and ensure they are leak-proof.

Material Compatibility: Materials used in valve construction should be compatible with the fluids handled and the operational environment to prevent corrosion or material degradation.

Training for Personnel: Proper training should be provided to personnel on the correct operation and maintenance of DBB valves to ensure safe handling.

Emergency Procedures: Establish and maintain clear procedures to be followed in emergencies, such as valve failures or leaks, to mitigate risks efficiently.

The Pressure Testing Process for DBB Valve

Start the pressure testing process for DBB valves by preparing the setup. Ensure correct installation and secure connections of the valve. Keep it closed to isolate the testing section from any flow. Then, fill the valve cavity and testing area with water, a safe choice for test fluid.

Next, gradually ramp up the pressure to a target usually above the valve’s maximum operational level. Maintain this pressure for a predetermined duration. During this time, watch for any pressure drops, which might signal leaks. Also, conduct a visual check for leaks.

After completing these checks, slowly release the pressure. Finally, record all test findings, such as pressure levels and observations. These records are vital for compliance and future reference. This step-by-step approach ensures the valve’s integrity and reliability under actual operating conditions.

Advantages and Disadvantages

Advantages

DBB valve enhances safety by isolating pipeline sections. They reduce potential leak points and minimize system downtime. Operators can perform maintenance without fully depressurizing the system. These valves also provide precise flow control, boosting operational efficiency. Their compact design saves both space and installation costs. Additionally, their structure facilitates easier leak detection and pressure monitoring, thus enhancing system reliability and integrity.

Disadvantages

However, DBB valves have their drawbacks. They are costly to purchase and maintain. These valves require precise installation and skilled operation. Their complex design might increase the risk of mechanical failure. Regular maintenance is crucial for their reliability. In systems with limited space, fitting these valves can be problematic. Furthermore, finding replacement parts can often be challenging.

The Maintenance Requirements of the DBB Valve

Maintaining DBB valves is crucial for their optimal performance and longevity, involving several essential steps. Start with regular inspections to spot signs of wear, corrosion, or leaks. It’s important to check seals and gaskets for any damage that could compromise the system.

Next, focus on lubrication. Apply suitable lubricants to the valve’s moving parts to minimize friction and prevent wear. This step is key in ensuring smooth operation. Cleaning is also critical; regularly remove debris or buildup from valve components.

Another vital maintenance task is seal replacement. Replace seals and gaskets regularly to avoid leaks and maintain pressure integrity. Alongside these tasks, periodically perform operational testing. Ensure the valve opens and closes smoothly and correctly.

Additionally, conduct pressure tests to affirm the valve’s ability to hold required pressure levels. Document all maintenance activities thoroughly, including inspections, repairs, and replacements. This documentation is essential for tracking the valve’s history and planning future maintenance.

Finally, ensure that all personnel handling the valves receive proper training. They should understand the specific maintenance procedures for DBB valves to maintain their efficiency and safety.