Description

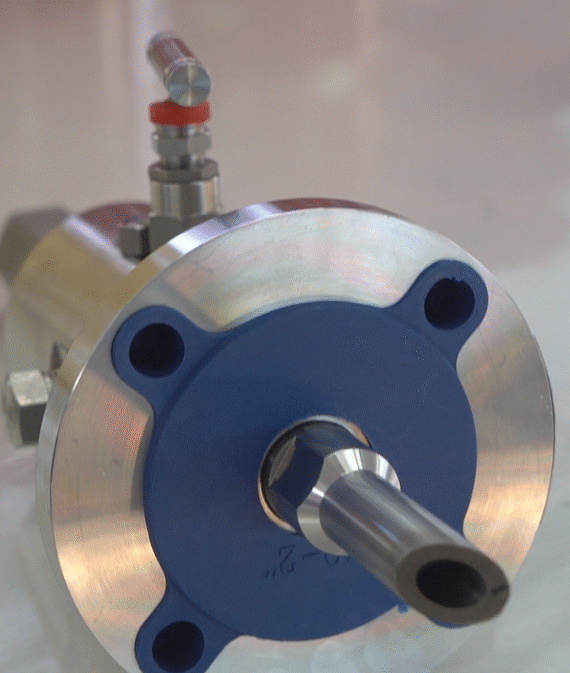

Introduction To Injection Quill

The EMT-CI injection quill in piping is a specialized device designed to ensure the effective delivery of chemicals into pipelines. Which is crucial for maintaining the integrity and performance of piping systems across various sectors. The primary purpose of the Injection Quill is to facilitate precise and controlled injection of chemicals, such as corrosion inhibitors, without disrupting the pipeline’s operation. This is vital in preventing premature wear and tear, corrosion, and blockages that can lead to pipeline failure. Its role extends beyond maintenance to include aspects of safety and efficiency, making it an essential component in any industrial setting where chemicals are used to treat pipelines.

Overview of Industries Served

The versatility of the EMT-CI Injection injection quill in piping allows it to serve a broad spectrum of industries, highlighting its adaptability to different operational needs and environments:

- Building Material Shops. In these facilities, the quill is to administer chemical treatments in the production processes. Where pipelines are integral to transporting raw materials.

- Construction Works. Here, it plays a role in maintaining equipment used in construction, ensuring that machinery operates efficiently without the risk of pipeline clogging or damage.

- Energy & Mining. The quill is crucial for the energy sector, particularly in mining operations where harsh chemicals and abrasive materials are common, requiring robust systems that can withstand aggressive environments.

- Oil & Gas. Perhaps its most critical application, in oil and gas pipelines, the Injection Quill ensures the longevity and reliability of pipeline infrastructure, which is fundamental to operational success and environmental safety.

Construction and Material Quality

Details of the Materials Used

The construction of the EMT-CI Injection Quill involves materials chosen for their strength, durability, and chemical

compatibility:

- 316L Stainless Steel. This material is for the solid plug assembly, injection tube, and NPT nozzle. Known for its corrosion resistance and strength, 316L stainless steel can withstand a wide range of temperatures and chemical exposures, making it ideal for harsh industrial environments.

- ASTM A105N for the Flange. ASTM A105N, a carbon steel material known for its good tensile strength and thermal conductivity, is used for the flange. This material is chosen for its ability to maintain physical integrity under high pressure and varying temperatures. Which are common in industrial pipelines.

Benefits of Using High-Quality Materials

Using such high-quality materials ensures that the Injection Quill is not only durable but also resistant to the harsh environments found within the industries it serves. The resilience of 316L stainless steel and ASTM A105N carbon steel ensures that the quill can perform under extreme conditions without failure, thereby:

- Reducing the risk of leaks and spills, which can be costly and environmentally damaging.

- Minimizing maintenance needs and operational downtime, which in turn reduces overall operating costs.

- Enhancing the safety of the workplace by preventing accidents and chemical exposures.

Design Features of Injection Quill

Sealing Material: Fluororubber

Sealing Material: Fluororubber

The EMT-CI Injection Quill incorporates fluororubber for its sealing elements, a choice driven by the material’s superior performance characteristics:

- Chemical Compatibility. Fluororubber is renowned for its exceptional resistance to chemicals, including various types of fuels, oils, and solvents, making it ideal for use in environments where chemical exposure is frequent.

- Temperature Resilience. Able to withstand temperatures ranging from -20°C to 200°C, fluororubber ensures that the seal maintains its integrity and functionality even under extreme thermal conditions.

Benefits in Preventing Leaks and Enhancing Safety and Efficiency

The use of fluororubber in the quill’s design directly contributes to enhanced operational safety and efficiency:

- Preventing Leaks. The robust chemical and temperature resistance of fluororubber minimizes the risk of seal degradation, thus preventing leaks that could lead to environmental hazards and operational disruptions.

- Enhancing Safety and Efficiency. By maintaining a tight seal, the quill ensures that chemicals are injected precisely where needed, optimizing the use of chemicals and reducing waste. This precise control also enhances the safety of the chemical injection process, preventing exposure and potential accidents.

Operational Capabilities

Supported Working Pressures: 150LB to 1500LB

- Versatility in Pressure Requirements. From low-pressure systems (150LB) to high-pressure environments (1500LB), the quill ensures reliability and performance, adapting to different system demands without compromising on safety or efficiency.

Modular Design

- Ease of Installation and Maintenance. The modular design of the quill allows for quick and easy assembly and disassembly. This feature is essential in reducing installation times and simplifying maintenance procedures.

- Reduction of Downtime and Labor Costs. By facilitating easier maintenance, the modular design helps minimize operational downtime and reduces the labor costs associated with regular upkeep and emergency repairs.

Application Across Systems with Varying Pressure Requirements

The quill’s ability to function across a range of pressures ensures that it can be integrated into almost any existing chemical injection system without the need for extensive modifications, offering high adaptability and scalability.

Certifications and Reliability of Injection Quill

ISO9001 Certification

- Quality Assurance. The ISO9001 certification signifies that the EMT-CI injection quill in piping meets international standards for quality management, ensuring consistent performance and reliability.

Role in Injecting Chemicals Like Corrosion Inhibitors

- Controlling Corrosion. By allowing for the precise injection of corrosion inhibitors, the quill plays a critical role in extending the lifespan of pipelines by preventing corrosion, which is a major cause of pipeline degradation.

Importance in Controlling Corrosion and Extending Pipeline Lifespan

- Long-term Benefits. The effective management of corrosion not only extends the operational life of pipelines but also enhances safety and reduces the likelihood of costly repairs and environmental damage.