Description

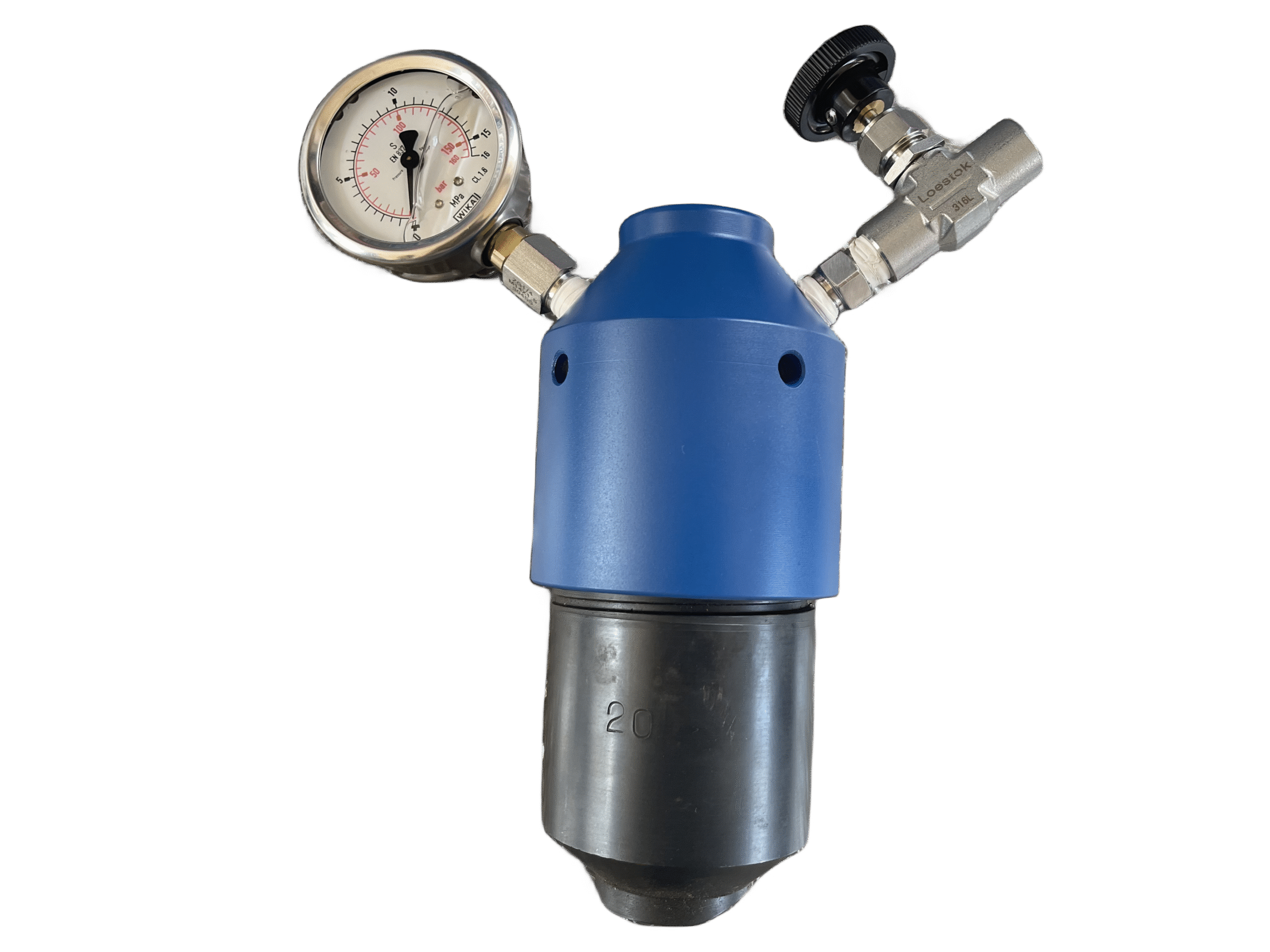

The model weld access fitting body is designed to be welded directly to the pipe or vessel. The corrosion access fitting incorporates a radius to match the curvature of the pipe or vessel.

It also includes a thick body to provide sufficient branch reinforcement areas to help strengthen the welded joint. This is the most popular type of installation configuration for corrosion accessories.

Technical Specifications of EMT Access Fitting

| Specification | Description |

|---|---|

| Mounting Style | Flareweld connection with integral branch reinforcement per ASME B31.3 |

| Temperature Range | Standard seals (Viton/Teflon) support -15°F (-26°C) to +400°F (+204°C) |

| Pressure Rating | Rated for 6,000 PSI (41.3 MPa) working pressure; higher ratings available upon request |

| Installation Method | Direct weld to pipe or vessel for a compact, cost-effective solution |

| Compliance Standards | Fully compliant with NACE MR0175 and MR0103 for sour service materials |

| Certifications | Canadian Registration Number (CRN) approved and conforms to PED requirements |

Key Benefits

Pressure-Tolerant Operation: Allows maintenance or removal while the system remains under full operating pressure.

Built-In Check Valve: Standard design includes an integral check valve for added safety and reliability.

Durable Construction: Precision-machined components ensure long-lasting, robust performance.

Corrosion-Resistant Materials: Injection and sampling components available in high-performance alloys for superior corrosion resistance.

Safe Chemical Injection: Designed to safely handle a broad range of chemical injection applications.

Threaded Connection Options: Available with internal ACME threading for secure and easy installation.

Versatile Component Selection: Choose from various injection tubes, quills, and nozzles to meet specific application needs.

Applications of Access Fitting

EMT chemical injection equipment is designed for versatility and reliability, making it suitable for use with a wide variety of chemicals across numerous industries and applications.

In the oil and gas industry, it plays a critical role in processes such as corrosion inhibition, scale prevention, and hydrate control. It is equally valuable in chemical processing environments, where precision and material compatibility are essential for safe and effective chemical delivery.

Pipeline operations benefit from its ability to inject additives and inhibitors directly into the flow stream, ensuring system integrity and reducing downtime. In heavy manufacturing, the equipment supports various treatments vital to maintaining the performance and longevity of machinery and infrastructure.

Additionally, EMT systems are ideal for cooling systems, where chemical dosing is required to control biological growth, scaling, and corrosion. Across all these sectors, EMT chemical injection solutions deliver robust performance and reliable results.