Description

Basic Working Principle of Hydraulic Corrosion Probe

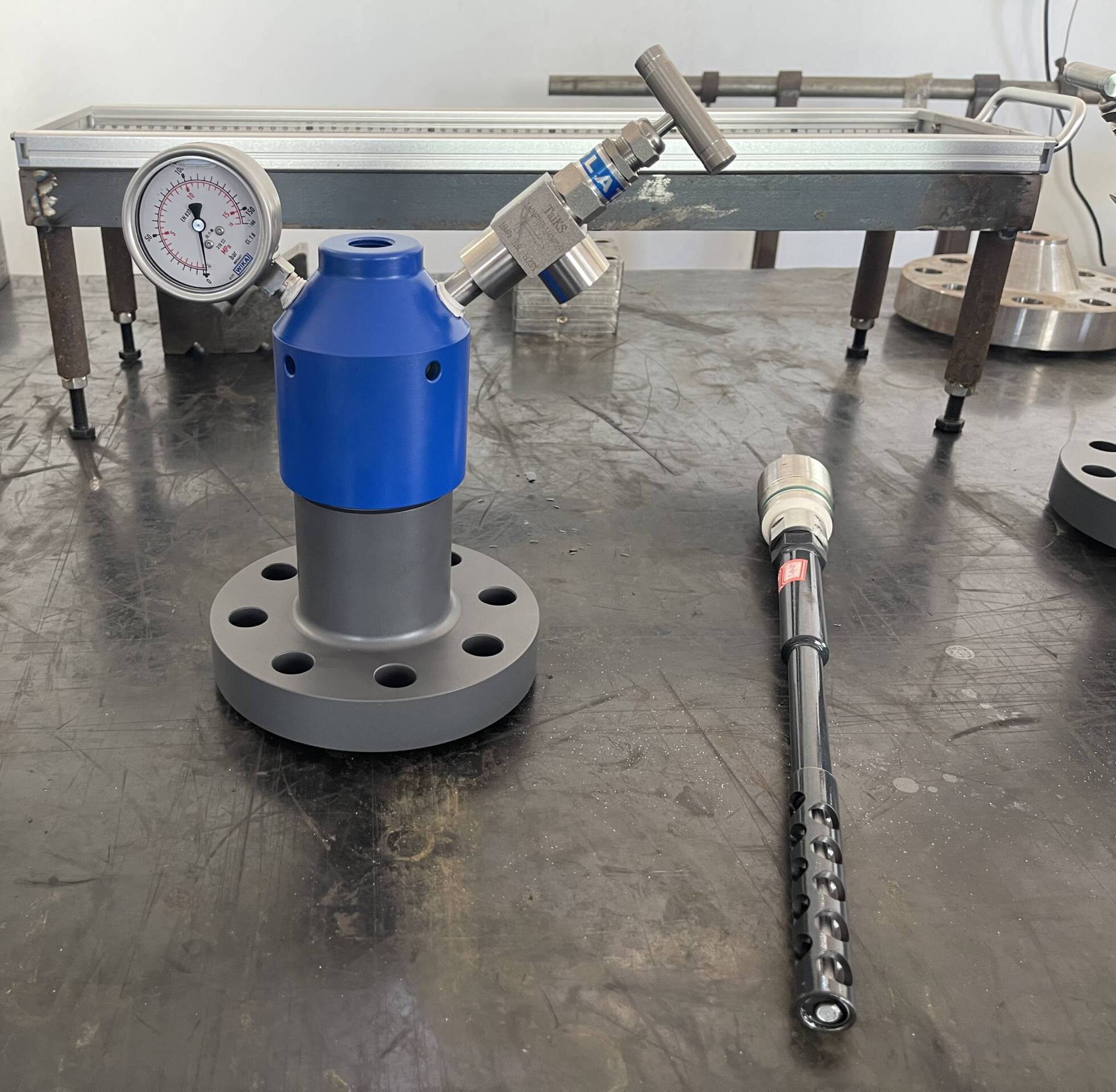

The core of this Hydraulic Corrosion Probe sensor is a corrodible mechanical diaphragm, which serves as a substitute element for the pipeline material, mimicking the corrosion behavior of the pipeline itself.

-

Mechanical Response Principle: The sensor operates by monitoring changes in the response of the diaphragm under the inherent pressure inside the pipeline. The deformation of the diaphragm under a given pressure depends on its material properties and geometric dimensions, particularly its thickness. When corrosion reduces the thickness of the diaphragm, its deformation under the same pressure changes.

-

Signal Detection: Highly precise instruments (such as resistance strain gauges, capacitive or optical techniques) quantify the deformation of the diaphragm. This enables the detection of minute changes in diaphragm thickness, facilitating high-resolution monitoring of cumulative mass loss and allowing for rapid assessment of corrosion rates.

Main Technical Features and Advantages of Hydraulic Corrosion Probe

Compared to traditional corrosion monitoring technologies, this mechanical probe has the following standout features:

-

Combines Two Measurement Capabilities: It bridges the gap between traditional Electrical Resistance (ER) probes and Linear Polarization Resistance (LPR) probes. ER probes excel at measuring cumulative loss, while LPR probes are good for rapid measurement of instantaneous corrosion rates. This new sensor can achieve both functions within a single device.

-

Unaffected by Medium Conductivity: Its sensing principle is mechanical and does not rely on the conductivity of the monitored medium. Therefore, it is not interfered with by changes in process fluid conductivity or multiphase flow, which are common challenges for electrochemical techniques like LPR.

-

Wide Range of Applications: Due to these characteristics, it is suitable for monitoring corrosiveness in various industrial processes such as drinking water, oil and gas, chemicals, and power generation.

Application Areas

This technology aims to provide a more reliable and adaptable online corrosion monitoring solution for industrial sites. Its design goal is to enable continuous monitoring of cumulative corrosion and rapid corrosion rates, particularly in complex operating conditions where traditional electrochemical methods are less effective.

Brief Comparison with Other Corrosion Monitoring Technologies

For a more comprehensive understanding, here is a reference to other mainstream technologies mentioned in the search results:

-

Linear Polarization Resistance (LPR) Probe: Rapidly determines the instantaneous corrosion rate by applying a small overpotential and measuring the current response, but requires a conductive medium.

-

Electrical Resistance (ER) Probe: Determines cumulative metal loss by measuring the change in resistance of a metal sensing element as it thins due to corrosion. It offers high sensitivity, but data can be affected by temperature and stress.

-

Hydrogen Probe: Specifically used to monitor the tendency of hydrogen atoms generated by corrosion reactions to permeate metal, assessing the risk of hydrogen damage (e.g., hydrogen embrittlement, blistering). It comes in pressure-type and electrochemical-type variants.

-

Ultrasonic Monitoring Technology: Examples include using phased array probes for corrosion mapping or utilizing guided wave technology for large-area average wall thickness monitoring. These are non-intrusive or offline/online inspection methods.

The hydraulic corrosion probe is essentially an innovative sensor based on the mechanical diaphragm principle. It monitors thickness loss caused by corrosion with high precision by measuring the deformation of the diaphragm under process pressure. Its main advantages are that it does not depend on medium conductivity and can simultaneously assess cumulative loss and instantaneous corrosion rates, giving it unique application value in various industrial corrosion monitoring scenarios.