Description

Improve Pipeline Efficiency with a Quick Opening Closure

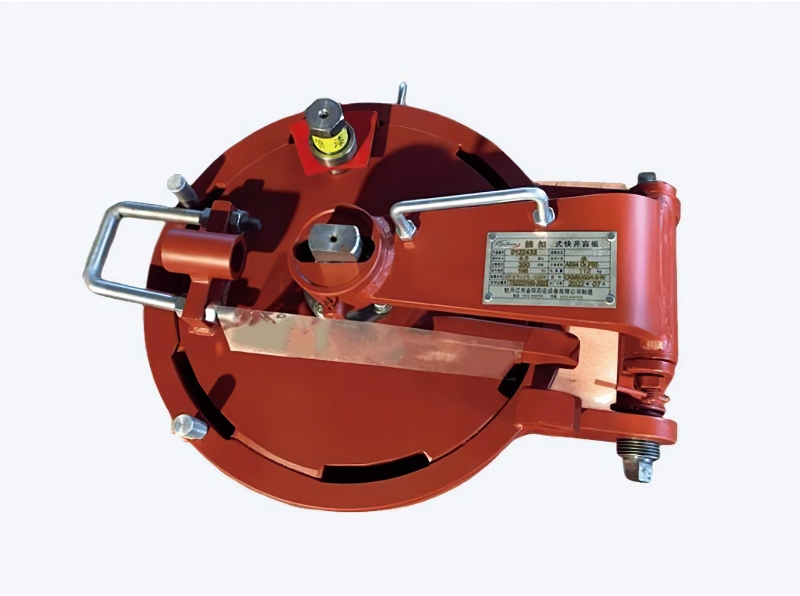

A Quick Opening Closure plays a vital role in modern pressure vessel and pipeline systems. It offers fast and safe access for inspection, cleaning, and maintenance. Industries such as oil, gas, and petrochemicals rely heavily on this device.

Unlike traditional closures, a Quick Opening Closure reduces downtime significantly. Operators can open and close it within minutes. As a result, teams maintain productivity and safety with minimal disruption.

What Is a Quick Opening Closure?

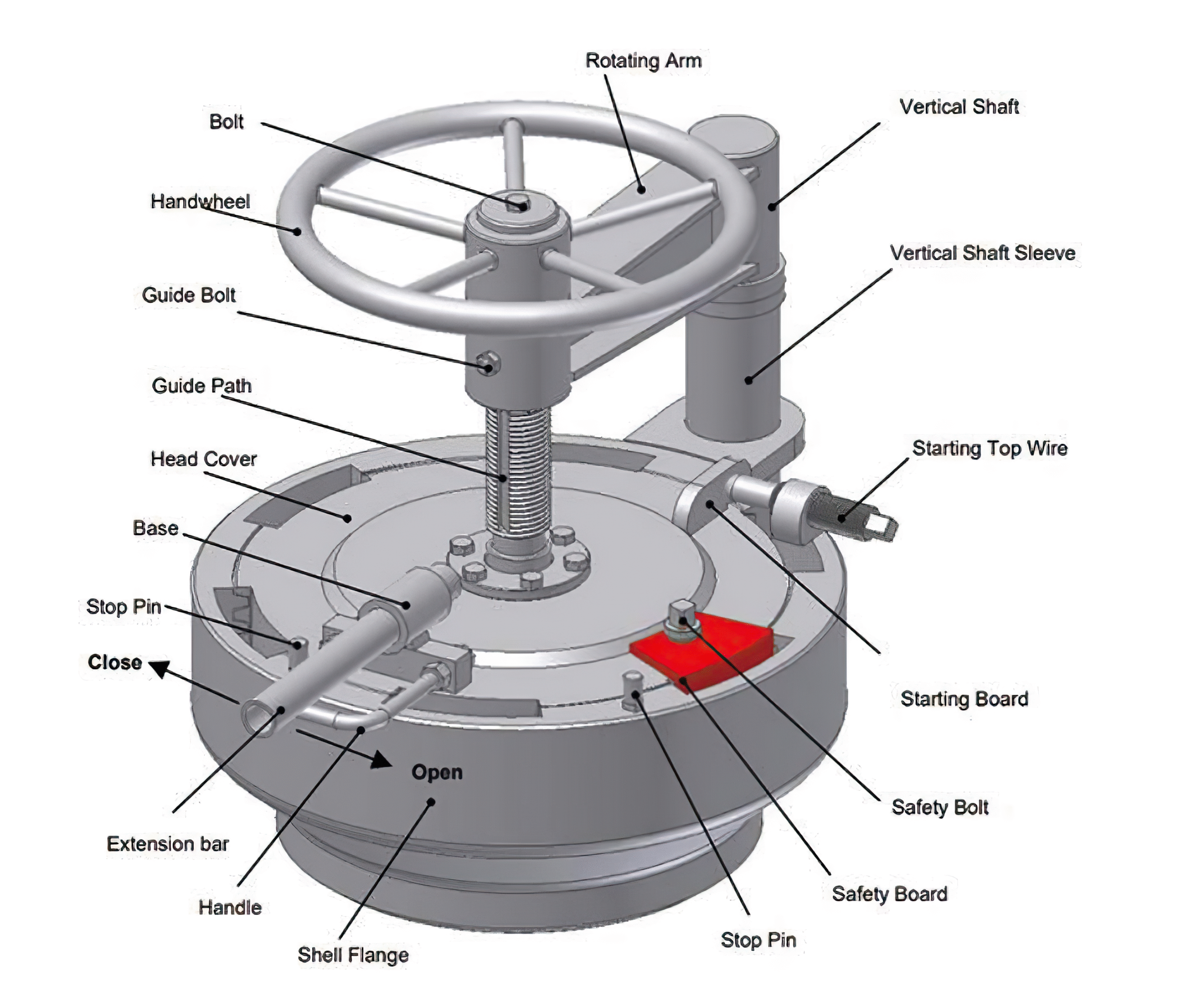

A Quick Opening Closure, often referred to as QOC, is a mechanical device. It seals the end of pressure vessels and pipeline systems. Once depressurized, operators can open it quickly without tools.

Most closures include safety locks, pressure alerts, and sealing mechanisms. These features prevent accidents and ensure easy operation. Therefore, the Quick Opening Closure has become a standard in many critical industries.

Benefits of Using a Quick Opening Closure

First, the Quick Opening Closure saves time. Operators can access the pipeline or vessel fast. This reduces maintenance windows significantly.

Second, it improves safety. Built-in safety interlocks prevent opening under pressure. So, workers stay protected during every operation.

Third, it lowers labor costs. Since it opens without wrenches or bolts, fewer tools and workers are required. As a result, companies save resources.

Moreover, the Quick Opening Closure offers excellent sealing performance. It handles high pressure and temperature with ease. That’s why it remains reliable even in harsh environments.

What Is an Inserted Type Quick Opening Closure?

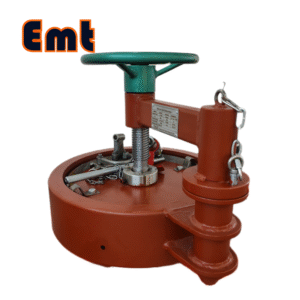

The Inserted Type Quick Opening Closure is a specific design variation. It features an inserted locking mechanism that ensures better sealing and easier operation.

Operators prefer the closure for vertical vessels and pig launchers. It suits applications that require frequent opening and closing.

Additionally, the closure handles high internal pressure effectively. Its compact design also saves space. For tight installations or offshore use, it proves highly useful.

Many engineers select the Inserted Type Quick Opening Closure for its balance of safety and convenience. It combines robust engineering with user-friendly operation.

Applications of Quick Opening Closures

The Quick Opening Closure is used in various sectors. Oil and gas firms install it on pig launchers and receivers. Petrochemical plants use it for filter separators and pressure vessels.

In water treatment, it allows fast access to filtration units. Even food processing plants benefit from its easy-open design.

Because the Quick Opening Closure works well in both horizontal and vertical pipelines, it adapts to many systems. Operators value its flexibility and durability.

How to Choose the Right One

First, check your pressure and temperature requirements. A reliable Quick Opening Closure must meet ASME and PED standards.

Second, choose the right size and type. You’ll find elliptical, torispherical, and vertical models. The Inserted Type Quick Opening Closure works best for tight spaces or frequent use.

Third, consider material compatibility. For corrosive fluids, stainless steel or coated carbon steel may be necessary.

Lastly, ensure the closure includes safety interlocks. These prevent operators from opening under pressure. That way, you ensure compliance and safety.

Installation and Maintenance Tips

Always follow the manufacturer’s guidelines. Proper installation ensures a long service life. Before operation, inspect the seals and locking components.

During maintenance, remove debris and lubricate moving parts. A clean Quick Opening Closure performs better and lasts longer.

For the Inserted Type Quick Opening Closure, check the alignment of the locking ring. This ensures smooth engagement and sealing.

Regular checks improve safety and reduce downtime. With good care, your closure can last for years without replacement.

Why Choose the Inserted Type Quick Opening Closure?

Many engineers prefer the Inserted Type Quick Opening Closure for its improved ergonomics. It provides reliable sealing with less manual effort. Moreover, it opens and closes faster than traditional models. For time-sensitive operations, this makes a big difference. If your site has limited space, the Inserted Type Quick Opening Closure offers a compact solution. You won’t need extra clearance or large tools. It’s also easier to train staff on this model. Its simple locking system reduces learning curves and operational errors.

Conclusion

In conclusion, a Quick Opening Closure is essential for efficient, safe, and cost-effective pipeline operations. It saves time, improves safety, and boosts productivity. Its compact design and easy operation make it a great choice for many industries. If you’re upgrading your system or designing a new one, consider installing a Quick Opening Closure. You’ll reduce downtime and improve operational efficiency—without compromising safety.