Description

1. Introduction of EMT Intrusive Pig Signaller

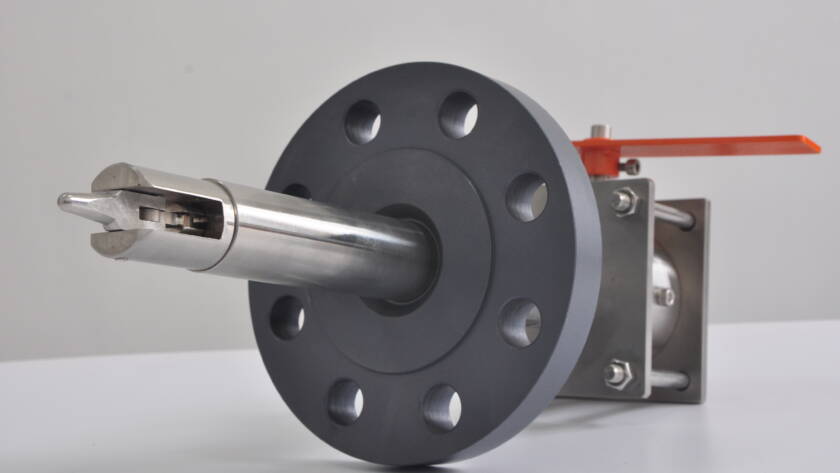

EMT Intrusive Pig Signaller is an essential tool used in the pipeline industry to confirm the passage of pipeline pigs—devices used for cleaning or inspecting pipelines. These signallers are strategically installed at significant locations such as pig launching and receiving stations as well as other critical points along the pipeline.

2. Design and Materials

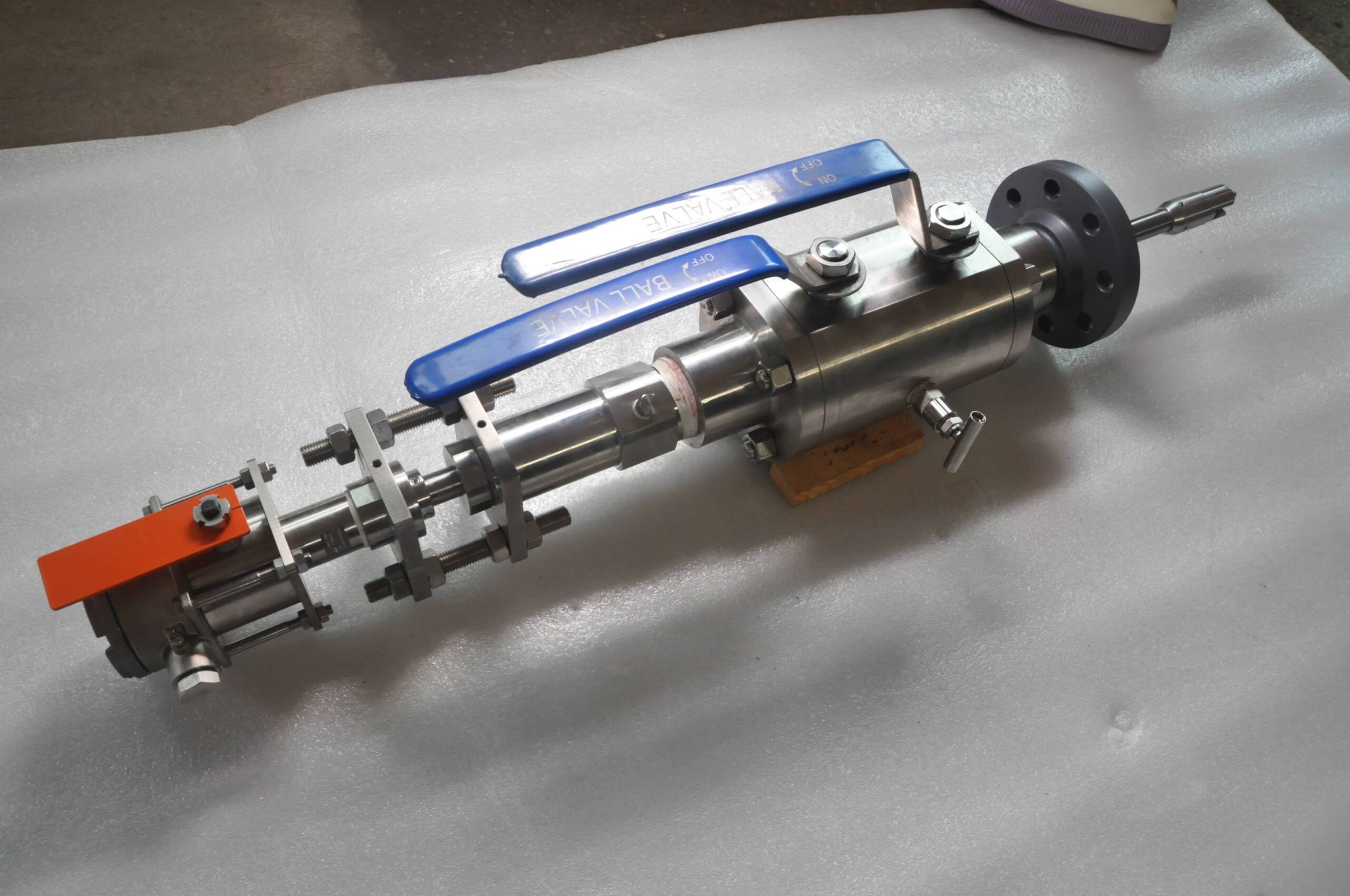

The EMT Bi-directional Intrusive Pig Signaller is notable for its adjustable range of 0-21mm, making it versatile for use in pipelines with varying wall thicknesses. This adaptability is crucial for ensuring that the signaller can operate effectively across different systems without the need for multiple specialized devices.

Materials used in the construction of these signallers include:

- Stainless Steel 304 and 316: Known for their corrosion resistance and durability, these materials are ideal for harsh pipeline environments.

- Duplex Stainless Steel F51 (DSS F51): Offers even greater strength and corrosion resistance, suitable for more demanding applications.

- Carbon Steel A105N: Provides a cost-effective option while still maintaining good strength and performance under high pressure.

- Inconel 625: Exceptional resistance to extreme temperatures and corrosive environments, ensuring longevity and reliability.

3. Key Features and Functions

a. Versatility:

EMT Pig Signallers are designed to accommodate a wide range of pipeline diameters and wall thicknesses, thanks to their adjustable range of 0-21mm. This makes them suitable for different types of pipelines, from oil and gas to water and chemical conduits.

b. Material Quality:

The choice of materials for EMT Pig Signallers includes:

- Stainless Steel 304 and 316: These provide excellent corrosion resistance and durability.

- Duplex Stainless Steel F51: Known for its superior strength and corrosion resistance, ideal for harsh environmental conditions.

- Carbon Steel A105N: Offers a balance of toughness and heat resistance at a more economical cost.

- Inconel 625: Exceptionally resistant to extreme environments, making it suitable for high-temperature and corrosive applications.

c. Installation and Maintenance:

These devices are designed to be lightweight and flexible, making installation straightforward even in complex or hard-to-reach pipeline sections. Their design also facilitates easy maintenance and manual resetting when necessary.

4. Types of Intrusive Pig Signaller

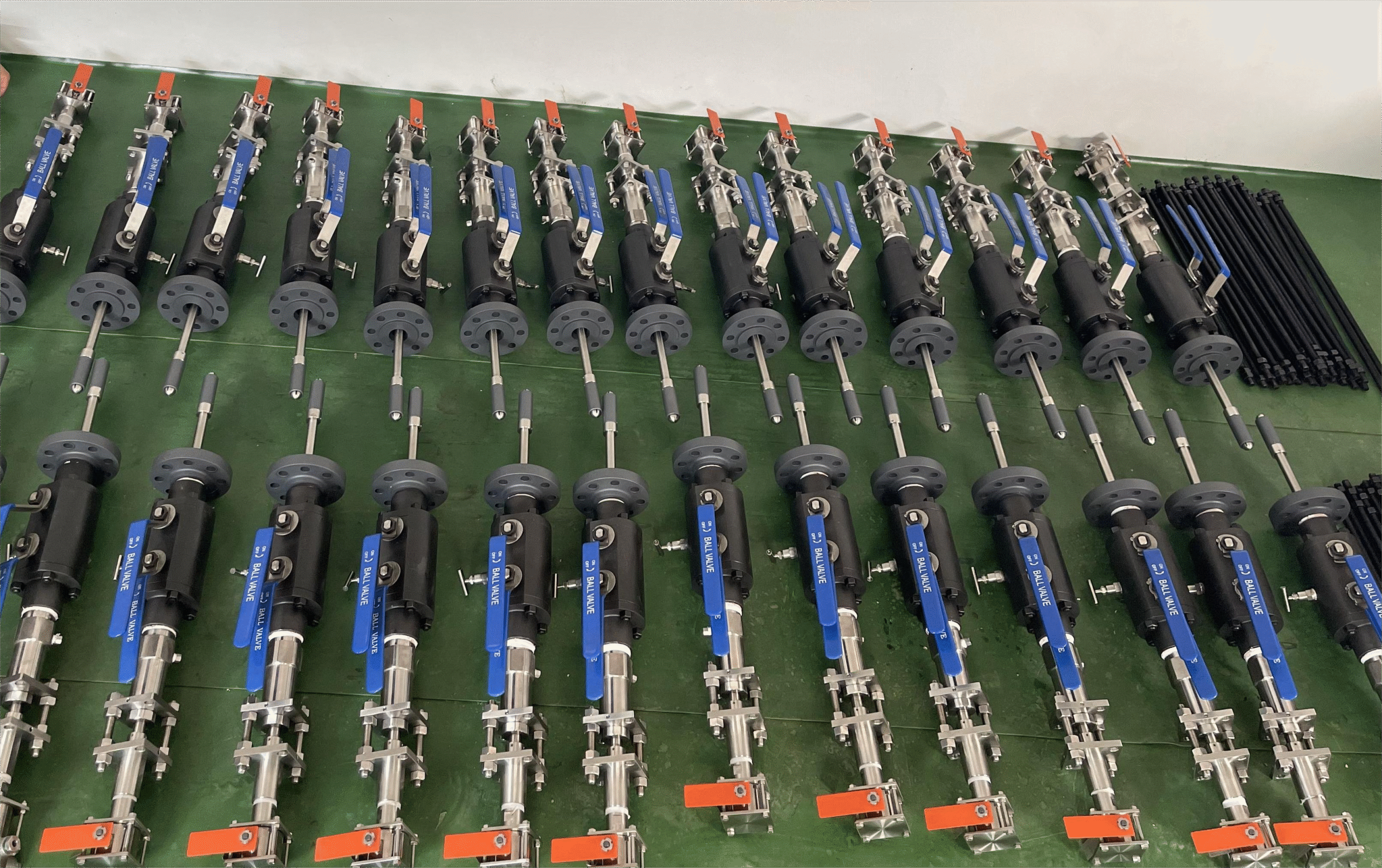

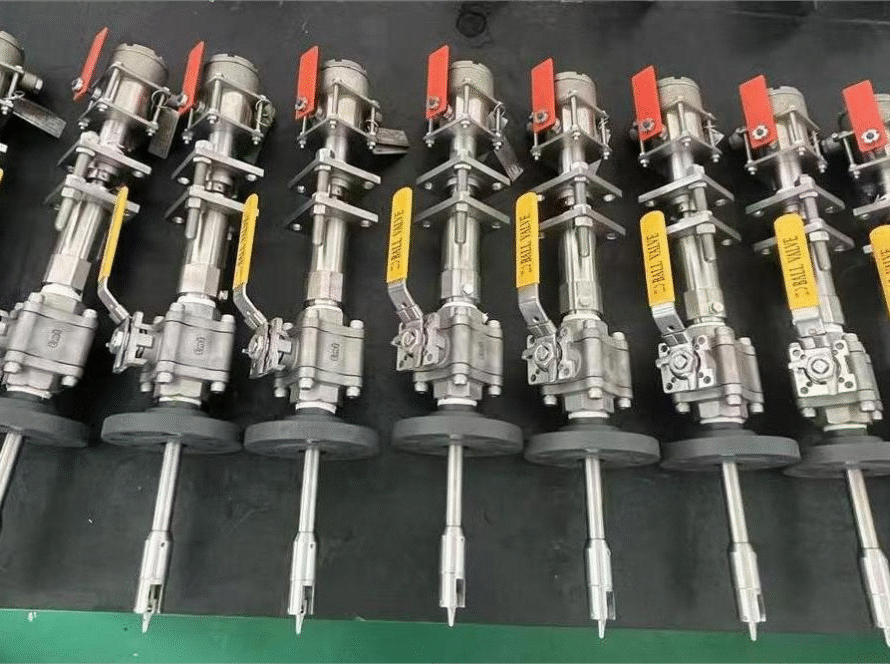

EMT offers various types of pig signallers to meet different operational needs and preferences:

- Non-Intrusive Models: These signallers detect the pig’s passage without penetrating the pipeline, ideal for applications where pipeline integrity is paramount.

- Intrusive Models: These models physically enter the pipeline and are directly activated by the pig’s passage, providing immediate and reliable detection.

Indicator Options

EMT Intrusive Pig Signaller come with different types of indicators to suit various monitoring requirements:

- Popper Type: A mechanical indicator that pops up when a pig passes by.

- Manual Reset Flag: Includes a visible flag that rises upon the pig’s passage and requires manual resetting.

- Combined Electrical Signals: Offers integration with electrical signals for automated monitoring systems, enhancing the capability to remotely track and confirm pig movements.

- Date and Time Display: Some models combine date and time information with electrical signals, providing detailed tracking information which can be vital for precise maintenance scheduling and historical data analysis.

5. Parameters

| Name | Intrusive Pig Signaller |

| Connection | Flange Connection |

| Plug body length | 200mm |

| Operating temperature | —20~120℃/Meet customer requirements |

| NACE MR 01- 75 | Yes |

| Ingress protection | IP65/IP66 |

| Explosion-proof class | ExdⅡ BT4 |

| Remove under pressure | No |

| Trigger type | Bi-directional/Uni-directional |

| Adjustable length | 0 |

| Internal part material | 316SS/DSS/INCONEL |

| Insert depth | 21mm(Bi)/13mm(Uni) |

| Flange/Body material | PTFE coated A105N/304SS/316SS/DSS/INCONEL(As per MR) |

6. Applications of EMT Pig Signallers

1. Oil and Gas

In the oil and gas industry, pipelines are the lifeline, carrying crude oil, natural gas, and refined products over long distances. EMT Pig Signallers are extensively used to ensure these pipelines remain clean and free of deposits like wax, scale, and other debris that could impede the flow or even cause blockages. Regular insertion of pigs, tracked by these signallers, helps in:

- Preventive Maintenance: Regular pigging operations, signaled by these devices, help in identifying potential problem areas where deposits are forming.

- Inspection and Monitoring: Smart pigs equipped with sensors and tracked by EMT signallers can gather critical data about the condition of the pipeline’s interior, such as corrosion or wear, crucial for preventive maintenance strategies.

- Safety and Compliance: Ensuring pipelines are clear and operational prevents leaks and ruptures, which are vital for environmental compliance and safety.

2. Water and Sewage

Water treatment and sewage systems rely on clear and functional pipelines to manage the flow of wastewater and treated water. EMT Pig Signallers help in:

- Blockage Prevention: Regular pigging signaled by these devices prevents the buildup of sediment, roots, and other obstructions in sewage lines.

- Maintenance Checks: They help in the routine maintenance checks to ensure that the pipelines are in good condition, which is crucial for municipalities to maintain public health standards.

- Leak Detection: In conjunction with inspection pigs, signallers can help pinpoint areas of leakage or weakness in water transport systems, especially in older pipelines.

3. Chemical

Chemical plants utilize pipelines to transport a variety of reactive and non-reactive chemicals. In such environments, pipeline integrity is not just a matter of efficiency but of utmost safety. EMT Intrusive Pig Signaller in these settings are crucial for:

- Contamination Prevention: Ensuring that the internal surfaces of pipelines are clean from any deposit or residue that could lead to contamination of transported chemicals.

- System Integrity Monitoring: Regular pigging operations, indicated by these signallers, can help detect early signs of corrosion or other wear that might compromise the pipeline’s integrity.

- Operational Efficiency: Maintaining clear pipelines ensures consistent flow rates and volumes, crucial for the precise mixing and reaction times needed in chemical production.

4. Additional Applications

Beyond these primary sectors, EMT Pig Signallers are also employed in other areas like:

- Food and Beverage: Where cleanliness and sanitation of pipelines carrying liquid ingredients or products are paramount.

- Pharmaceuticals: Where pipeline integrity directly affects the quality and safety of pharmaceutical products.