Description

Introduction to Lock Ring Pressure Vessel Closure

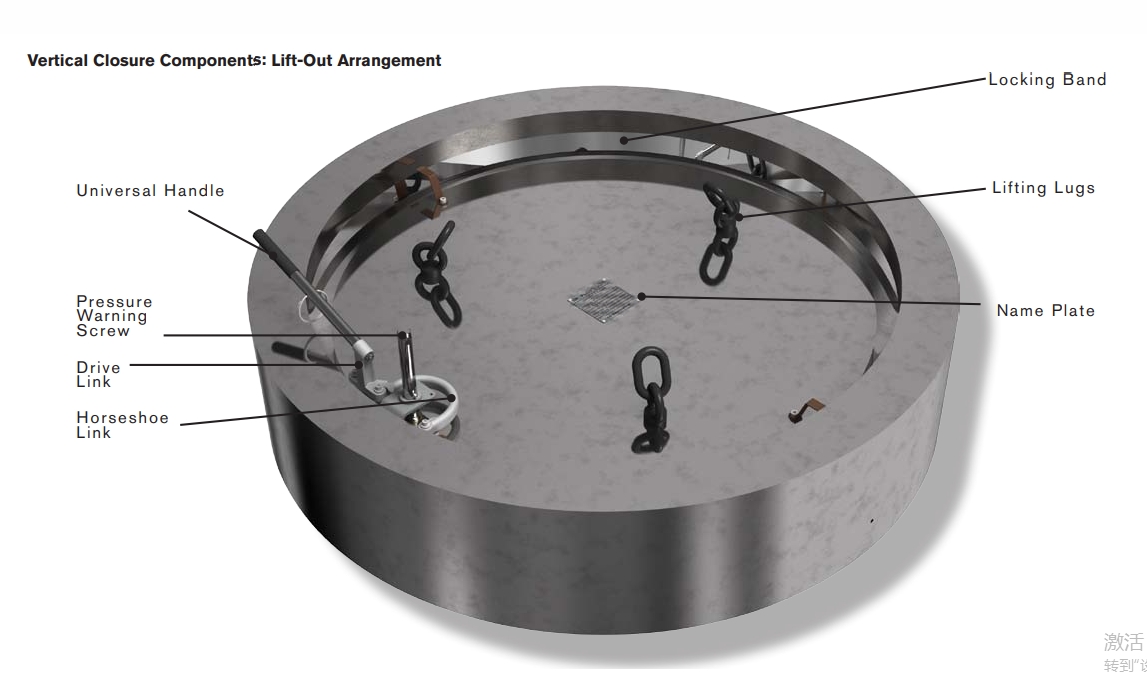

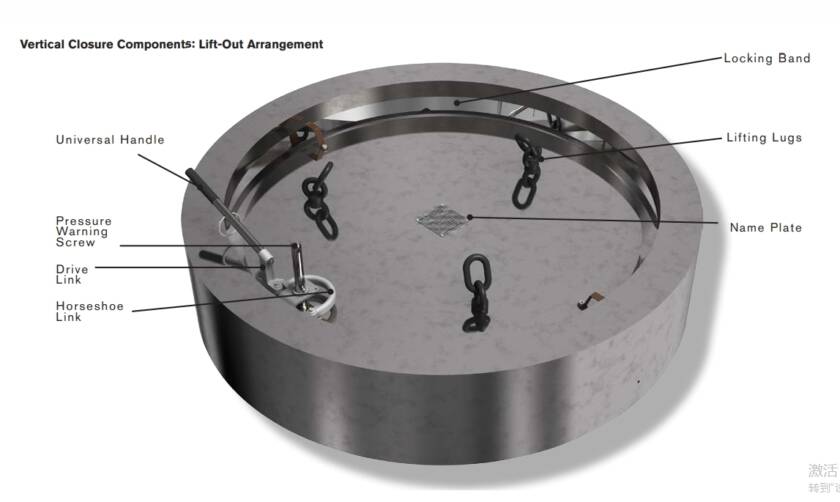

The Lock Ring Pressure Vessel Closure typically consists of several key components including a cylinder, flange, hook or clamp, sub, safety chain mechanism, opening and closing mechanism, and a swivel arm. To address common problems such as difficulties in opening the closure and leaks in the seal, it is essential to study the sealing structure, working principle, and functionality of these major parts. By analyzing typical failures that occur during the production process, it’s possible to diagnose issues and implement solutions. This ensures the safe and reliable operation of both the station and yard.

Sealing Principle of Lock Ring Pressure Vessel Closure

The sealing mechanism of the Lock Ring Pressure Vessel Closure features a U-shaped seal ring that fits snugly into a groove. On closing the blind door, the seal ring presses against the sealing surface due to applied pressure, creating an initial seal. As the system operates, the medium within the tube fills the inner cavity of the sealing ring. The high-pressure medium causes the seal to expand and press more firmly against the sealing surface, improving the seal. The effectiveness of the seal increases with the pressure. The design incorporates a self-tightening seal, which doesn’t require pre-tightening force or torque, ensuring reliable sealing without additional stress.

Structure

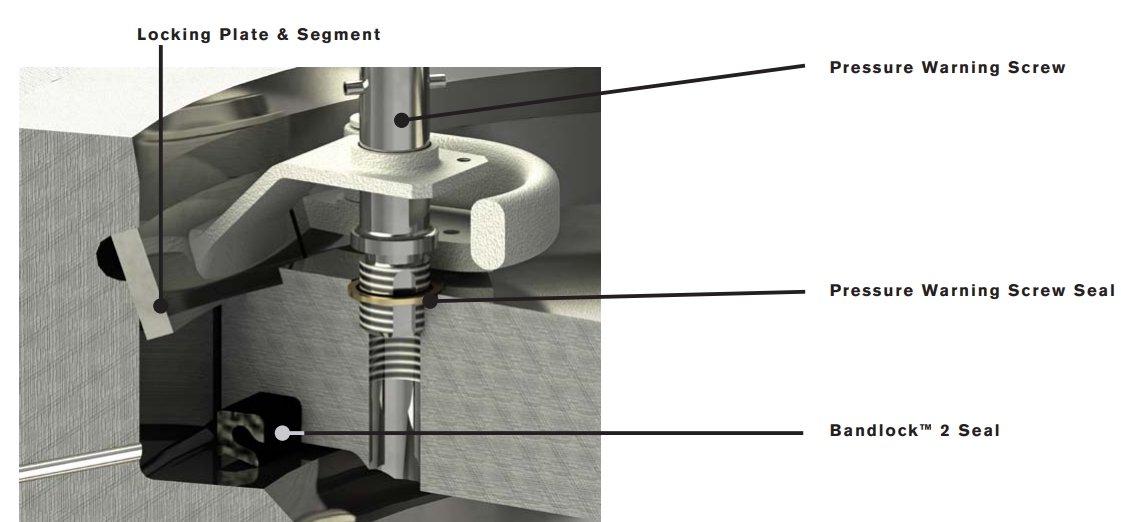

The closure’s safety mechanism includes a lock disc that enhances security. The lock ring cannot be removed, nor can the handle be turned, until the pressure alarm bolt is disengaged. The lock ring itself operates on a crank slider mechanism. Rotating the handle moves a guide column along a circular groove, adjusting the lock block’s position and altering the lock ring’s perimeter. This adjustment allows the lock ring to expand or contract within its slot. Turning the handle clockwise tightens the lock, securing the closure door, while turning it counterclockwise releases the lock and opens the door.

Safety Device

The safety lock plate stabilizes the ring lock by inserting it between two lever arms, preventing radial displacement. It is equipped with a pressure alarm bolt that must be removed before the safety plate can be detached. If there’s residual pressure within the system, loosening the bolt releases gas through a special port, emitting a sound to alert the operator. This feature prevents the potential danger of opening the closure under pressure, enhancing operational safety.

Opening and Closing of Lock Ring Pressure Vessel Closure

Opening

To open the Lock Ring Pressure Vessel Closure, first ensure all internal pressure is fully released. Free the closure from the bolt hole and remove the lock block. Insert one end of a universal handle into the hole on the lock ring drive arm. Rotate the handle counterclockwise, which retracts the lock ring into its groove. Finally, pull the door lever outward horizontally to swing the closure open.

Closing

For closing, insert the handle into the hole on the lock ring drive arm again. This time, turn the handle clockwise to extend the lock ring out into its corresponding groove. Push the lever inward to close the door, ensuring it seats properly into the neck of the Lock Ring Pressure Vessel Closure. Slightly loosen the lock ring so it just catches in the groove. Move the lever back and forth several times to ensure it is securely engaged. Reinstall the lock block and tighten the pressure alarm bolt to finalize the closure.

Maintenance of Lock Ring Pressure Vessel Closure

The Lock Ring Pressure Vessel Closure is designed with advanced safety features to significantly reduce risks associated with the operation of pressure vessels. The security mechanisms, particularly the safety lock ring, are crucial as they prevent the radial movement of the lock ring, minimizing the risk of accidental openings under pressure. This design is particularly important in applications involving pressure switches, where the stability of the closure is paramount to prevent unintended releases of pressure.

Despite these safety enhancements, there exist scenarios where additional precautions are necessary. One such concern arises if the pressure relief groove or the port of the pressure alarm bolt becomes clogged. In such cases, the primary safety feature designed to ensure no residual pressure remains inside the vessel before opening could fail. To mitigate this, operators must ensure the complete removal of the pressure alarm bolt, verifying that the internal pressure of the vessel has been fully neutralized. This step is critical to avoid any hazardous situations when accessing the inside of the vessel.

Furthermore, addressing the risks associated with hazardous substances inside the vessel, such as ferrous sulfide, is another critical safety measure. Ferrous sulfide can potentially lead to combustion or explosion if not handled correctly. To counteract this risk, it is advisable to spray water into the container before opening the closure fully. This process helps to absorb and dissolve ferrous sulfide, significantly reducing the likelihood of a chemical reaction that could lead to fire or explosion. This precaution is particularly vital in industries where the contents of pressure vessels can create combustible byproducts.