Description

Corrosion coupons remain the gold standard for quantitatively assessing internal corrosion rates in pipelines and process equipment. Traditional retrieval methods mandate costly and disruptive system shutdowns, depressurization, and production losses – an untenable scenario in today’s continuous-operation industries. Recognizing this significant operational and economic challenge, our company engineered a breakthrough solution: the Pressure-Retrieval Tool. This sophisticated mechanical system enables the safe extraction and installation of standard corrosion coupons under full operating pressure (≤45 MPa / 6,500 psi), eliminating downtime while delivering critical asset integrity data.

1. Core Engineering Principles

Constructed for uncompromising reliability in harsh environments, the tool employs a meticulously designed magnetically coupled, pressure-balanced mechanical system. Its architecture centers on:

-

Pressure Isolation & Management: A tri-valve system (Service Valve, Bleed Valve, Bypass Valve) ensures controlled isolation from and equalization with pipeline pressure.

-

Mechanical Force Transmission: An external Plug Lifter (strong magnetic neodymium steel) couples magnetically with internal components through the pressure boundary, transmitting rotational force via the Plug Drive gear assembly to engage/disengage the coupon.

-

Pressure Containment Integrity: Critical seals and dynamic components utilize advanced materials (PTFE coatings, specialized elastomers) compatible with target media and pressures.

-

Corrosion Resistance: Primary structural components (Housing, Valves, Adapter, Retriever, Drive Mechanism) are fabricated from high-grade 316 Stainless Steel, providing inherent resistance to corrosion, acids, and alkalis prevalent in oil, gas, and chemical service.

2. Key Technical Specifications of EMT Retrieval Tool

-

Maximum Working Pressure: 45 MPa (6,500 psi)

-

Temperature Range: -20°C to +100°C (-4°F to +212°F)

-

Compatible Media: Crude oil, refined petroleum products, natural gas (sweet), nitrogen, produced water, and other non-highly-corrosive fluids. (Not for H₂S service or highly oxidizing acids without specific material validation).

-

Installation Height: Typically ≤ 1.5 meters (dependent on pipe diameter and access configuration).

-

Coupon Standard: Compatible with standard NACE/ASTM corrosion coupon dimensions and threading.

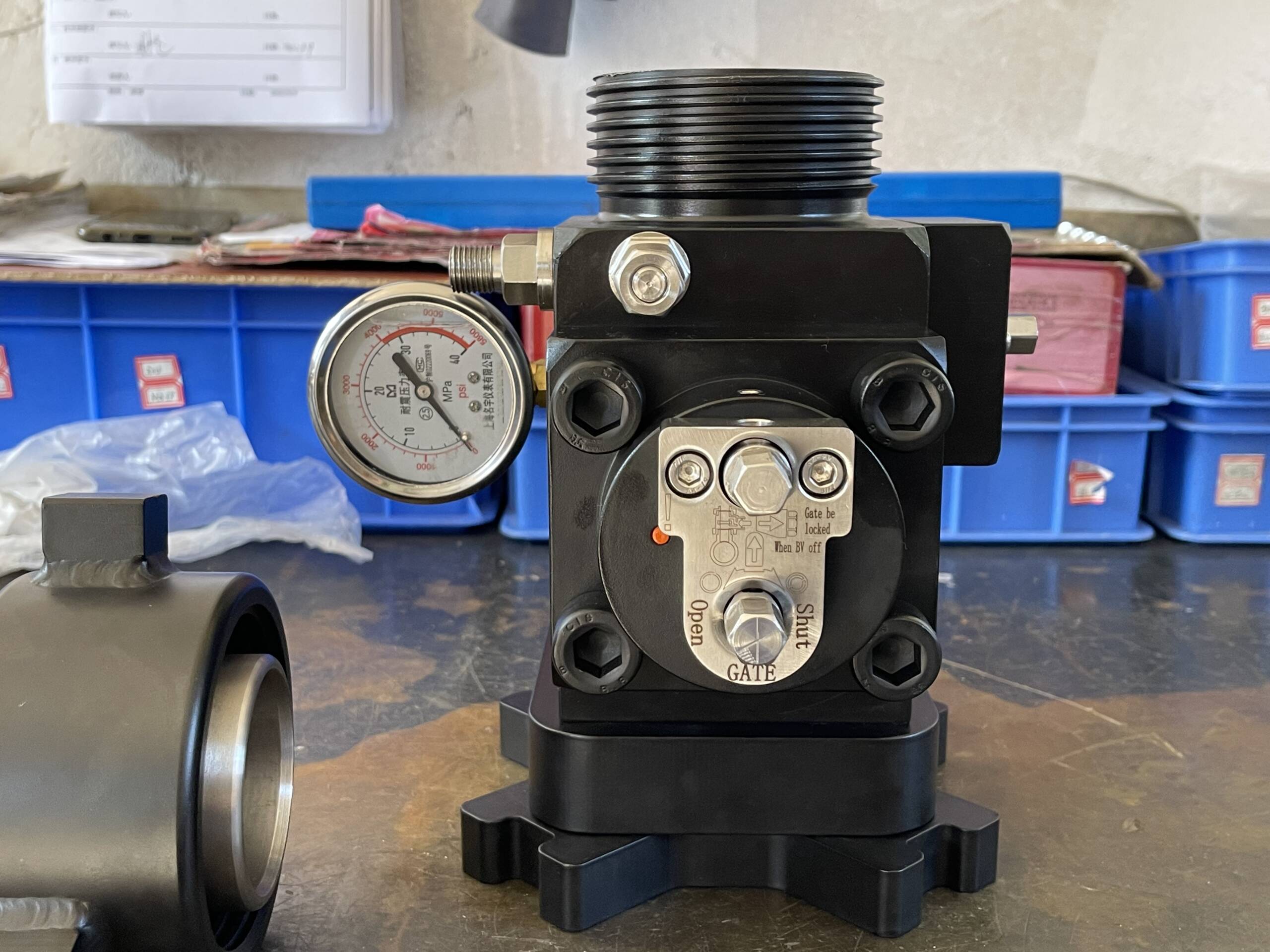

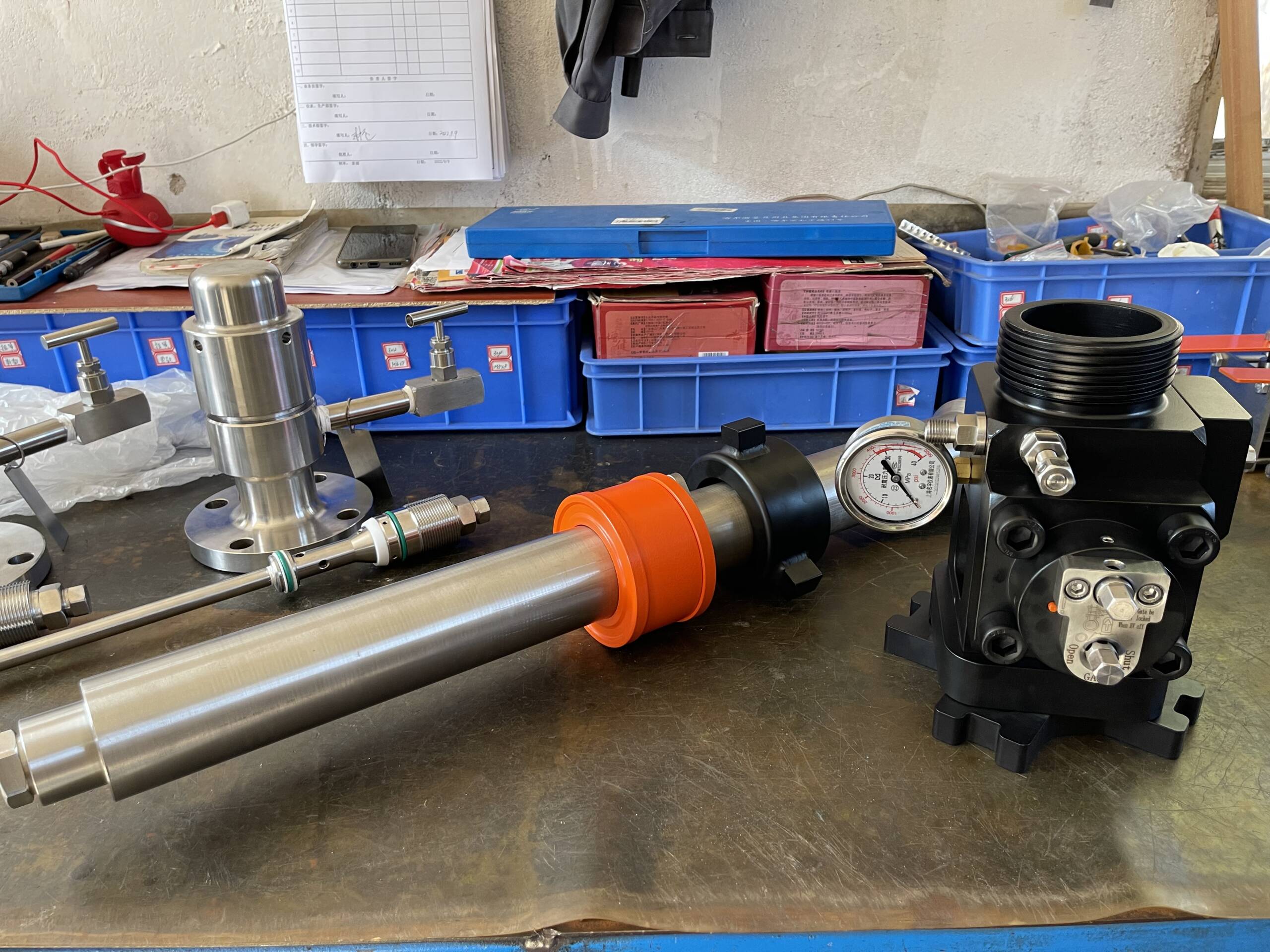

3. System Components of Retrieval Tool

The tool integrates several precision subsystems:

- Base & Hammer Nut: Provides primary connection to the pipeline access point (e.g., coupon holder assembly) and secures the Service Valve.

- Service Valve (PTFE Coated): The main isolation valve. Controls access between the pipeline and the tool’s internal chamber.

- Bleed Valve (Stainless Steel): Safely vents pressure from the tool’s internal chamber to atmosphere post-operation.

- Bypass Valve (Stainless Steel): Facilitates pressure equalization between the pipeline and the tool chamber prior to opening the Service Valve.

- Adapter (Stainless Steel): Interfaces directly with the corrosion coupon, connecting it to the Retriever shaft.

- Plug Drive (Stainless Steel): The gear-driven transmission assembly. Converts rotational input on the external drive shaft into linear motion (via magnetic coupling) to screw/unscrew the coupon. Clearly marked “Install” (Left-Hand Rotation) and “Retrieve” (Right-Hand Rotation).

- Plug Lifter (Strong Magnetic Steel): The external magnetic assembly. Moves linearly to transmit force magnetically to the internal drive mechanism. Features a Stop Block for secure upper position locking.

- Retriever (Stainless Steel): The main pressure housing containing the adapter and coupon during operation. Includes a top Sealing Screw for fluid filling/draining (required for high-pressure procedures >15 MPa) and air venting. Connects to the Service Valve.

- Seals & Coatings: High-pressure elastomer seals (e.g., HNBR, FKM) and PTFE coatings on critical sliding surfaces ensure smooth operation and long-term seal integrity.

4. Operational Advantages

-

Zero Production Downtime: Perform coupon changes without depressurizing or shutting down the pipeline, eliminating associated production losses and revenue impact.

-

Enhanced Personnel Safety: Minimizes exposure to hazardous fluids during retrieval/installation by maintaining containment within the tool.

-

Superior Data Frequency: Enables more frequent coupon changes for accurate, real-time corrosion rate trending and chemical treatment program optimization.

-

Reduced Operational Risk: Avoids the risks associated with system shutdown/startup cycles (e.g., hydrate formation, slugging, upset conditions).

-

Cost Efficiency: Eliminates costs of lost product, flaring, restart energy, and extended crew time required for traditional shutdown methods.

-

Versatility: Suitable for a wide range of pipeline applications in upstream, midstream, and downstream oil & gas, petrochemicals, and utilities.

5. Critical Safety Integration

Safety is paramount in pressurized systems. This tool incorporates intrinsic and procedural safeguards:

-

Valve Position Interlocks: Strict procedures govern valve sequencing (open/close states) during retrieval and installation to prevent uncontrolled energy release. CRITICAL WARNING: Misalignment of the Service Valve drive screw plane relative to the axis in the fully open/closed position risks catastrophic mechanical failure. Precise adjustment per the manual is mandatory (Refer Fig. 1 – Position Verification).

-

Pressure Staging: Controlled pressure equalization via the Bypass Valve prevents shock loading on components.

-

Controlled Depressurization: Dedicated Bleed Valve allows safe, gradual venting of trapped pressure after isolation.

-

High-Pressure Protocol (>15 MPa): Requires specific hydraulic oil filling/pressurization steps using a dedicated manual pump to balance forces before engaging the coupon mechanism.

-

Positive Mechanical Locking: The Plug Lifter Stop Block provides a secure mechanical lock in the raised position, preventing accidental lowering during pressurization.

6. Target Applications

This tool is indispensable for integrity management programs requiring continuous monitoring without interruption:

-

Pipeline Corrosion Monitoring Points (Onshore/Offshore)

-

Production Flowlines & Manifolds

-

Tank Farm Transfer Lines

-

Refinery & Petrochemical Process Piping

-

Gas Transmission Pipelines

-

Water Injection Lines

7. Maintenance of Retrieval Tool

Ensuring tool reliability demands strict adherence to post-operation maintenance:

-

Thorough Cleaning: Immediately after use, disassemble key components (Retriever, Adapter) and meticulously clean all internal and external surfaces, removing all process fluids and debris using compatible solvents. Dry completely.

-

Comprehensive Lubrication: Generously apply high-temperature, corrosion-inhibiting grease (e.g., lithium-based) to all O-rings, dynamic seals, threaded connections, and sliding surfaces (e.g., Plug Lifter shaft, Plug Drive gears). This prevents seal degradation, corrosion, and ensures smooth future operation.

-

Inspection: Visually inspect all components for wear, damage (especially seals, threads, magnetic surfaces), or corrosion before storage. Replace worn parts with genuine spares.

-

Storage: Store fully assembled or disassembled components in a clean, dry, climate-controlled environment, protected from physical damage. Ensure all valves are in the closed position and threads are protected.

Our Pressure-Retrieval Tool represents a significant technological advancement in pipeline integrity management. By enabling safe, efficient access to corrosion coupons under full operating pressure, it transforms a traditionally disruptive, costly procedure into a routine operational task. Engineered for robustness, safety, and reliability with premium materials and a fail-safe design, this tool delivers unparalleled operational and economic benefits, empowering asset owners to maintain peak production while proactively managing corrosion risks. Consult the comprehensive operation manual for detailed installation, retrieval, installation, and safety procedures prior to deployment.