Description

1. Understanding Metal Corrosion Coupons in Pipeline Testing

Metal corrosion coupons are essential tools in the field of industrial maintenance, particularly for assessing the corrosion rates within pipeline systems, heat exchangers, and cooling water systems. These standard metal specimens are suspended within test containers or directly in the operational equipment to monitor and evaluate corrosion levels over time.

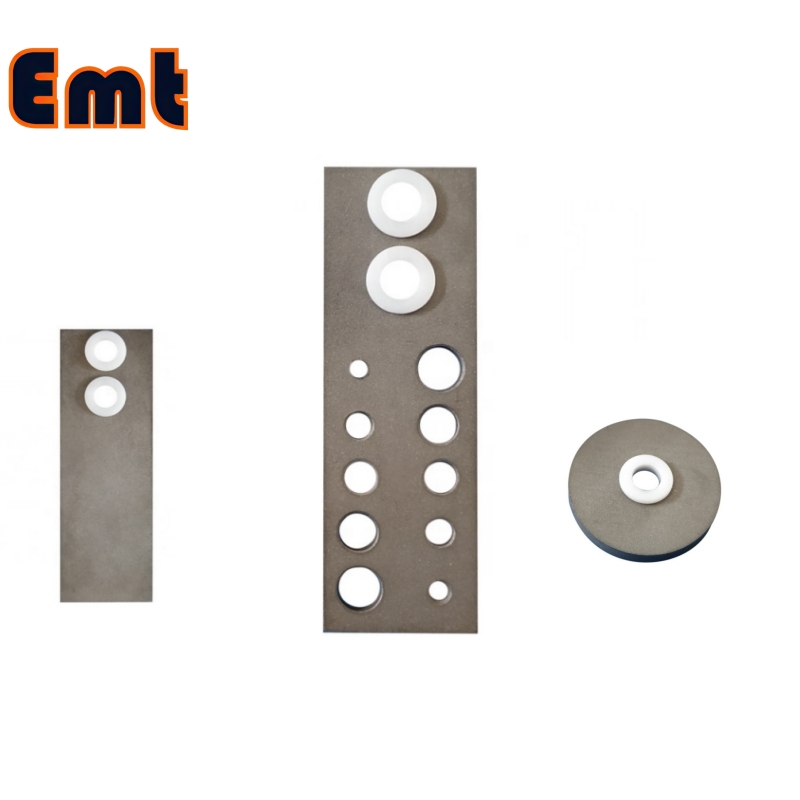

2. Composition and Types of Metal Corrosion Coupons

Corrosion coupons are made from various metals to match the pipeline material or to test specific corrosion reactions. So common materials include Stainless Steel 304, Stainless Steel 316, Duplex Stainless Steel F51, Carbon Steel A105N, and Inconel 625. These materials ensure that the coupons can withstand the operational conditions of most industrial systems, with operating temperatures ranging from -20 to +120 degrees Celsius.

3. Installation and Indicator Options

Metal Corrosion Coupon Access Fittings are designed for flexibility in installation, with options including:

- 2-inch flange connection

- 2-inch welded nipple

- 2-inch welded base with NPT nipple connection

These fittings can accommodate different types of corrosion coupons and offer various indicators for monitoring:

- Bi-directional and Bi-directional Feather types for dynamic environments where flow direction might change.

- Uni-directional types for more stable flow conditions.

To enhance usability and data retrieval, these fittings can be equipped with:

- Manual reset flags for simple visual indication.

- Electrical switch outputs for integration into automated monitoring systems.

- Digital displays for real-time data reading, combined with electrical switches for comprehensive monitoring.

4. Functionality and Features

a. Primary Functionality

Metal corrosion coupons serve as a critical diagnostic tool in the assessment of material degradation due to corrosion within industrial systems. The primary function of these coupons is to quantitatively measure the extent of metal loss over a predetermined exposure period. It typically set between 30 to 90 days, depending on the specific requirements of the system being monitored.

Once installed in a pipeline, vessel, or any other component susceptible to corrosion, these coupons undergo the same environmental conditions as the system itself. After the testing period, they are carefully removed, cleaned to remove any corrosion products, and then weighed. Sophisticated analytical techniques are used to measure the weight loss. Which is then converted into corrosion rate units, typically mils penetration per year (mpy). This metric is crucial as it provides a standardized rate of corrosion, allowing for comparisons across different environments or operational conditions.

b. Corrosion Type Identification

Beyond simply measuring the rate of corrosion, these coupons also provide invaluable data on the type of corrosion occurring within the system. By analyzing the patterns and forms of corrosion on the coupon’s surface—such as uniform attack, pitting, crevice corrosion, or intergranular corrosion—engineers can diagnose the specific corrosion mechanisms at play. So this information is vital for developing targeted strategies to mitigate corrosion. Which may include changes in material selection, adjustments in chemical treatment regimens, or alterations in operation conditions.

c. Design and Features

The design of metal corrosion coupons emphasizes several key features aimed at maximizing their utility and effectiveness:

- Ease of Operation: Metal corrosion coupons are designed to be user-friendly. So they come equipped with features that simplify installation and retrieval from test sites. This ease of operation ensures that personnel can handle them without specialized training, reducing the likelihood of errors during installation or post-exposure analysis.

- High Accuracy: Accuracy is paramount when measuring corrosion rates, as even small miscalculations can lead to significant misunderstandings about the system’s integrity. Corrosion coupons are manufactured to high precision standards with rigorously controlled dimensions and compositions to ensure consistent and reliable data.

- Longevity and Durability: While the coupons themselves are sacrificial elements, they are designed to last through the entire predetermined exposure period without disintegrating or losing structural integrity. Then this durability is crucial for ensuring that the data collected is representative of the entire testing period.

- Cost-Effectiveness: Despite their high reliability and precision, metal corrosion coupons are relatively inexpensive to produce and implement. Then this cost-effectiveness makes them an attractive option for routine monitoring in a wide range of industrial settings, from small-scale operations to large, complex systems.

- Lightweight and Flexible Nature: The physical characteristics of corrosion coupons—being lightweight and somewhat flexible—facilitate easy handling and installation. This feature is particularly beneficial in complex systems with difficult-to-access areas, as it minimizes the disruption to regular operations during installation and retrieval.

5. Why Choose Metal Corrosion Coupons?

Because choosing metal corrosion coupons for pipeline testing offers several advantages:

- High Accuracy: They provide precise measurements of corrosion rates, essential for maintaining the integrity and efficiency of industrial systems.

- Cost-effectiveness: Despite their high efficacy, corrosion coupons are a low-cost option for routine monitoring.

- Ease of Use: The simple design allows for easy installation and maintenance without the need for extensive training or specialized tools.