Description

Introduction

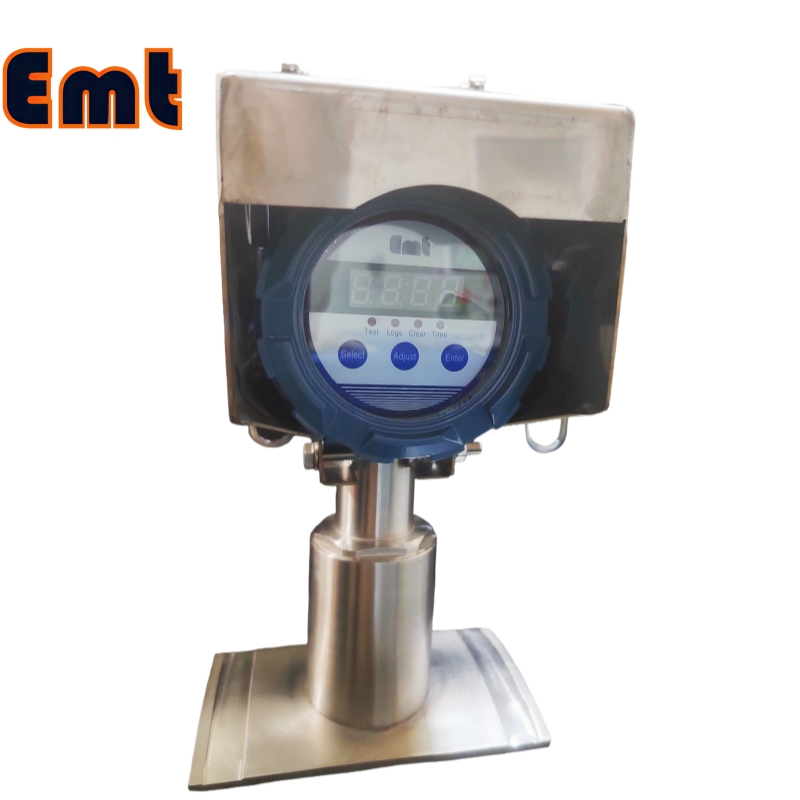

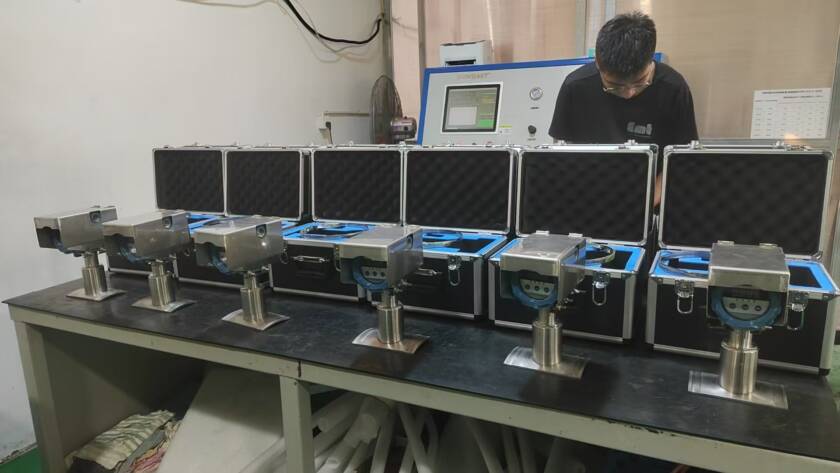

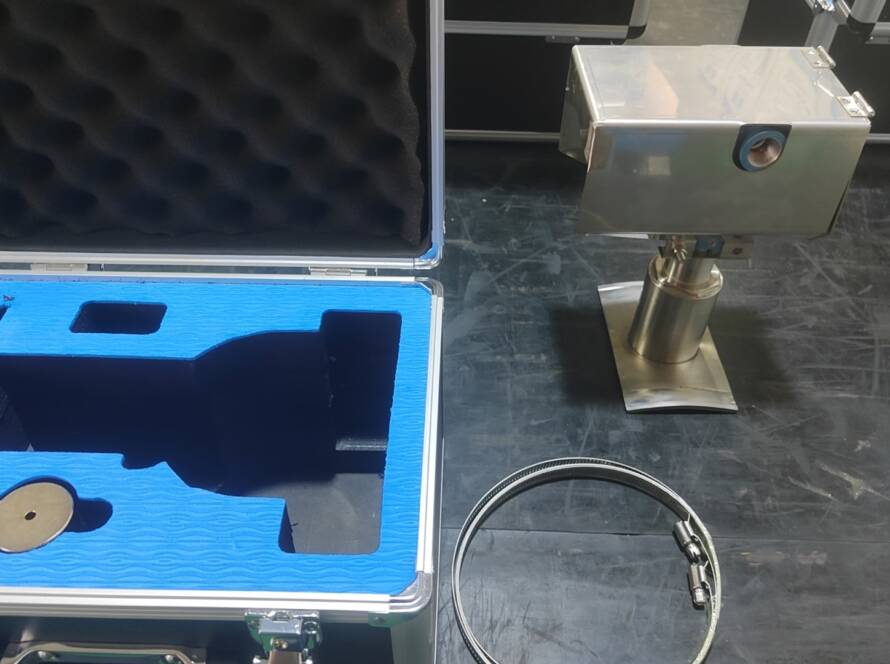

The Non-Intrusive Pig Detector is a sophisticated device designed for oil and gas pipelines to detect the presence of a “pig” — a tool used for cleaning or inspecting pipelines. This device is crafted with high-quality materials including Stainless Steel 304, Stainless Steel 316, Duplex Stainless Steel F51, Carbon Steel A105N, and Inconel 625, ensuring durability and resistance to various operational environments.

Parameters of Non-Intrusive Pig Detector:

| Parameter | Description |

|---|---|

| Material | Stainless Steel 304, 316, Duplex Stainless Steel F51, Carbon Steel A105N, Inconel 625 |

| Operating Temperature | -20°C to +120°C |

| Mounting Options | 2-inch flange connection, 2-inch welded nipple, 2-inch welded base-NPT nipple connection |

| Indicator Types | Manual reset flag, Electrical switch output, Digital display |

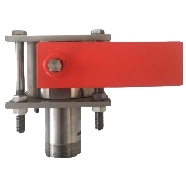

| Trigger Types | Bi-directional, Bi-directional Feather, Uni-directional |

| Operating Environment | Suitable for harsh, corrosive, and high-temperature environments |

| Features | High wear resistance, Good cleaning performance, Low cost |

| Applications | Oil and gas pipelines |

| Benefits | Enhanced pipeline efficiency, Operational safety, Cost-effective maintenance, Improved monitoring capabilities |

| Certifications | ISO 9001 certified |

Key Features and Attributes:

- Material Durability.: Robust materials like Stainless Steel and Inconel ensure high wear resistance and the ability to withstand the harsh conditions typical within pipelines. These materials contribute to the detector’s longevity and reliability.

- Operating Temperature.: The device operates effectively within a temperature range of -20°C to +120°C, making it versatile for different climatic conditions and operational demands.

- Functional Design.: The detector features a high cleaning performance, which is essential for maintaining the efficiency and safety of pipeline operations. It is lightweight and flexible, facilitating easy installation and handling.

- Technology and Indicators:

- Three Trigger Types.: The detector has Bi-directional, Bi-directional Feather, or Uni-directional modes, depending on the specific requirements of the pipeline system.

- Indicator Options.: It is equipped with either a manual reset flag, a manual reset flag combined with an electrical switch output, or a digital display with an electrical switch output. These options provide maximum flexibility in monitoring and control.

- Mounting Options.: Installation is simplified with three mounting types available: 2-inch flange connection, 2-inch welded nipple, or a 2-inch welded base-NPT nipple connection. These options allow for compatibility with various pipeline configurations.

- Cost-Effectiveness and Efficiency.: Despite its advanced features and durable construction, the Non-Intrusive Pig Detector is to be cost-effective. It offers low maintenance costs due to its non-use of dynamic seals and controlled emissions.

Advantages:

- Enhanced Pipeline Efficiency.: By ensuring thorough cleaning and maintenance tracking, the detector helps maintain optimal pipeline flow and prevents blockages.

- Operational Safety.: The robust construction and reliable operation minimize the risk of pipeline failures and associated hazards.

- Cost-Effectiveness.: Designed to be low maintenance and durable, the detector reduces the overall cost of ownership by minimizing downtime and maintenance expenses.

- Improved Monitoring.: The various indicator options enhance the ability to monitor and respond to pigging operations remotely and in real-time, improving operational responsiveness.

- Environmental Resistance.: Its materials and design make it suitable for harsh environments, ensuring long-term reliability and performance.

Applications of Non Intrusive Pig Detector

Here’s a detailed look at its various applications:

1. Pipeline Maintenance and Cleaning

- Detection of Cleaning Pigs.: The detector is used to confirm the passage of cleaning pigs that scrape and sweep away deposits, such as wax, scale, and other residues that can accumulate inside the pipelines. This helps in maintaining the optimum flow of the pipeline contents.

- Scheduling Maintenance.: By providing accurate data on pig passage, the detector allows operators to better schedule maintenance and cleaning operations, ensuring minimal disruption to the pipeline service.

2. Pipeline Integrity and Inspection

- Inspection Pigs.: It detects the passage of smart pigs or inspection pigs that work for inline inspection of pipelines. These pigs gather critical data about the condition of the pipeline, such as thickness, corrosion levels, and anomalies.

- Preventative Maintenance.: The information provided by the detector helps in preventative maintenance planning, allowing for early detection of potential pipeline issues before they develop into serious problems.

3. Safety and Compliance

- Leak Detection.: By ensuring that inspection pigs have passed through specific sections of the pipeline, the detector indirectly assists in leak detection and compliance with safety regulations.

- Verification Tool.: It serves as a verification tool to ensure that all segments of the pipeline are regularly inspected and maintained. Which is often a regulatory requirement in many regions.

4. Operational Efficiency

- Minimized Downtime.: The ability to detect pig passage without interrupting the pipeline operation allows for continuous monitoring without the need for shutdowns. Therefore it can minimize downtime.

- Accurate Positioning.: The detector provides operators with real-time information on the pig’s location, enhancing operational decisions about flow management and pig retrieval.

5. Cost Management

- Reduced Operational Costs.: By providing timely data, the detector helps in optimizing the maintenance schedule, reducing the need for emergency repairs, and extending the lifespan of the pipeline.

- Cost-effective Monitoring.: The non-intrusive nature of the detector means that it can be installed without major modifications to the pipeline. Which also makees it a cost-effective solution for ongoing pipeline monitoring.

6. Environmental Protection

- Prevent Spills.: By ensuring that pipelines are properly maintained and regularly inspected, the detector helps prevent spills and environmental damage, aligning with environmental protection standards.