Description

Introduction to Pig Barrel Closure

The Pig Barrel Closure is a crucial component in contemporary pipeline systems, crafted to boost both operational efficiency and safety. It acts as a vital mechanism enabling quick and secure access for pigging operations, which are essential for the routine cleaning and maintenance of pipelines. This capability plays a key role in minimizing downtime and maintaining a steady flow of materials such as oil, gas, and other substances.

Purpose in Pipeline Maintenance

The primary function of the Pig Barrel Closure is to offer an easy and secure entry point for the insertion and retrieval of pipeline pigs. In fact, these pigs are indispensable tools in the cleaning and inspection processes. As a result, they are crucial for avoiding blockages and preserving the integrity of the pipeline infrastructure. Moreover, the closure’s design greatly simplifies the complexities involved in pipeline maintenance tasks.

Key Features of the Pig Barrel Closure

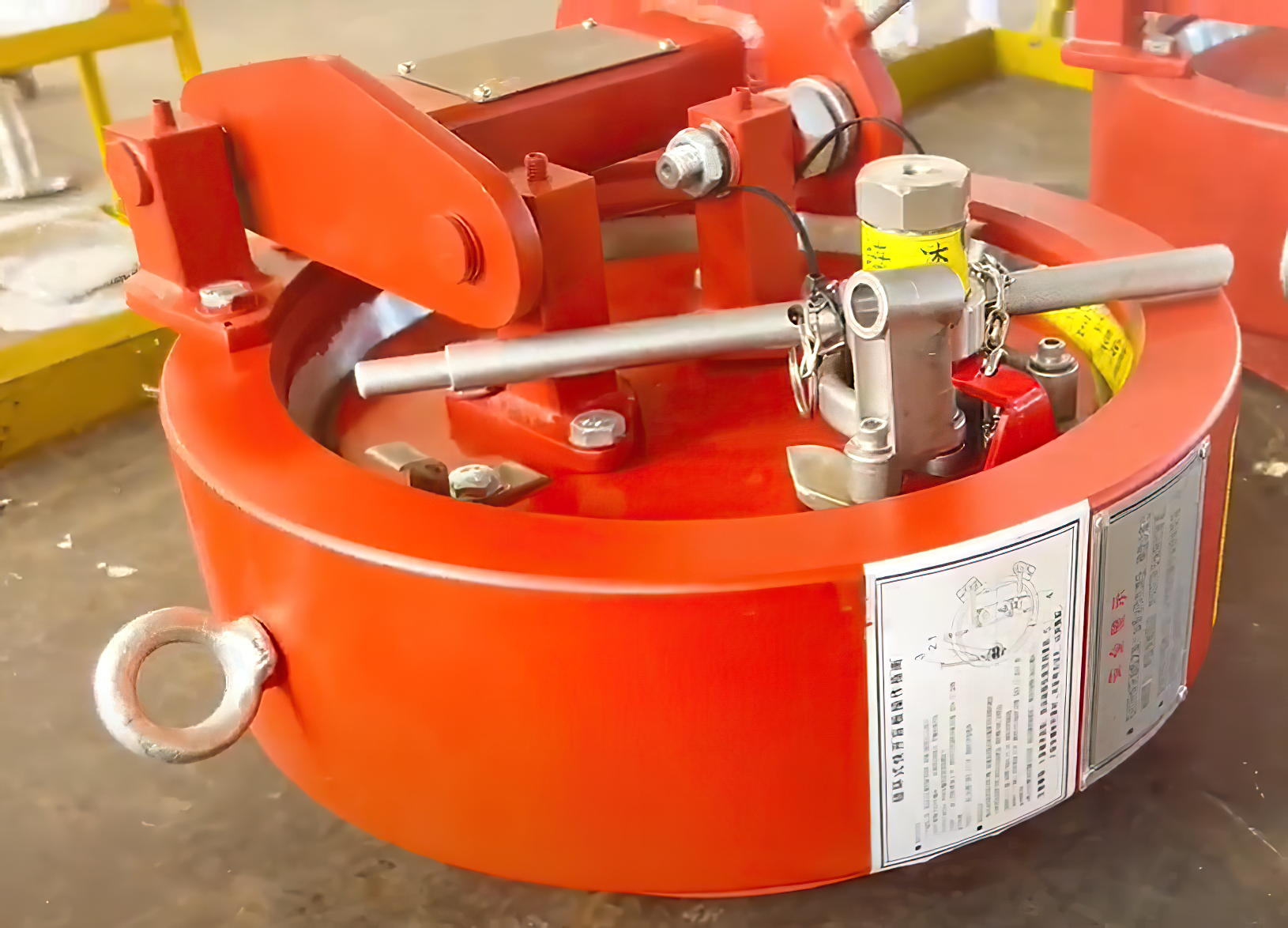

Valve Clamps and Accessories:

The valve clamps and accompanying accessories are critical for a tight and secure closure. These components are designed to meet the operational demands of pipeline systems. Because of these features, it ensures that the closure remains securely fastened and can be opened without compromising the pipeline’s integrity or operator safety.

Orientation Flexibility:

Designed to accommodate both vertical and horizontal setups, the Pig Barrel Closure offers significant versatility. This adaptability is crucial for conforming to different pipeline configurations and orientations, enhancing its utility across various applications.

Safety and Convenience

Quick and Convenient Operation:

The Pig Barrel Closure is engineered for swift and easy operation using commonly available standard tools. This ease of use is essential during both routine maintenance and emergencies, allowing operators to promptly access the pipeline for pigging or inspections without undue delays.

Safety Interlock Device:

A pivotal safety feature is the safety interlock device. It ensures that the closure can only be opened when the pipeline is fully depressurized. This prevents the accidental opening under pressure, which could result in dangerous blowouts or other safety hazards. Moreover, this system ensures pressure is only reintroduced once the closure is securely locked. This upholds a high level of safety during operations.

The comprehensive review of these features highlights the vital role of the Pig Barrel Closure. It enhances the safety, efficiency, and convenience of pipeline operations. By integrating robust design elements and safety mechanisms, the closure ensures effective and secure maintenance. Therefore this supports the overarching aim of maintaining pipeline integrity and continuous operation.

Parameters

| Design Conditions | ||

| 1 | Pipeline Size | From 6″ up to 56″ |

| 2 | Design Code | ASME VIII Div 1; ASME B31.3; ASME B31.4; ASME B31.8, etc. |

| 3 | Design Factor | 0.5, 0.6, 0.7, etc. |

| 4 | Corrosion Allowance | 0-5mm or more |

| 5 | Design Pressure | CL150, CL300, CL600, CL900, CL1500, CL2500, or as required. |

| 6 | Design Temperature (Min/Max) | -50℃ / 200℃ |

| 7 | Closure Type | Clamp Ring Type Quick Opening Closure |

| 8 | Installation Orientation | Horizontal, Vertical, Inclined |

| 9 | Applicable Medium | Gas, Oil, Petroleum, Chemical Materials, Water, etc. |

| Structure and Main Materials | ||

| 1 | Major Barrel/Min Barrel | ASTM A106, ASTM A516 Gr.70, or as required. |

| 2 | ASTM A515 Gr.70, ASTM A516 Gr.70, | |

| Quick Opening Closure | And ASTM A105, ASTM A350 LF2 Class1, | |

| (with Interlock System) | ASTM A694 F42 F46 F48 F50 F52 F56 F60 F65 F70, | |

| or as required. | ||

| 3 | Sealing Ring for the Closure | Viton, Nitrile |

| 4 | Saddle Support | Q235, or as required. |

| 5 | Flange | ASTM A105, ASTM A694 F70, or as required. |

| 6 | Lifting Lug/Eyes | Q235, or as required. |

| 7 | Grounding | Yes |

| 8 | Name Plate | Stainless Steel, or as required. |

| Certificates | ||

| 1 | ASME U Stamp Certificate | Applicable |

| 2 | Third-Party Inspection | BV, SGS, ABS, DNV, or as required. |

Operation of the Pig Barrel Closure

Operating the Pig Barrel Closure involves a series of steps designed to ensure safety and efficiency throughout the process. Here’s a detailed breakdown of each stage of operation:

Disengaging the Safety Interlock Device:

The operation begins by ensuring the pipeline is depressurized, which is critical for safety. Engaging the safety interlock device prevents the closure from being opened while the pipeline is pressurized, thereby mitigating potential hazards.

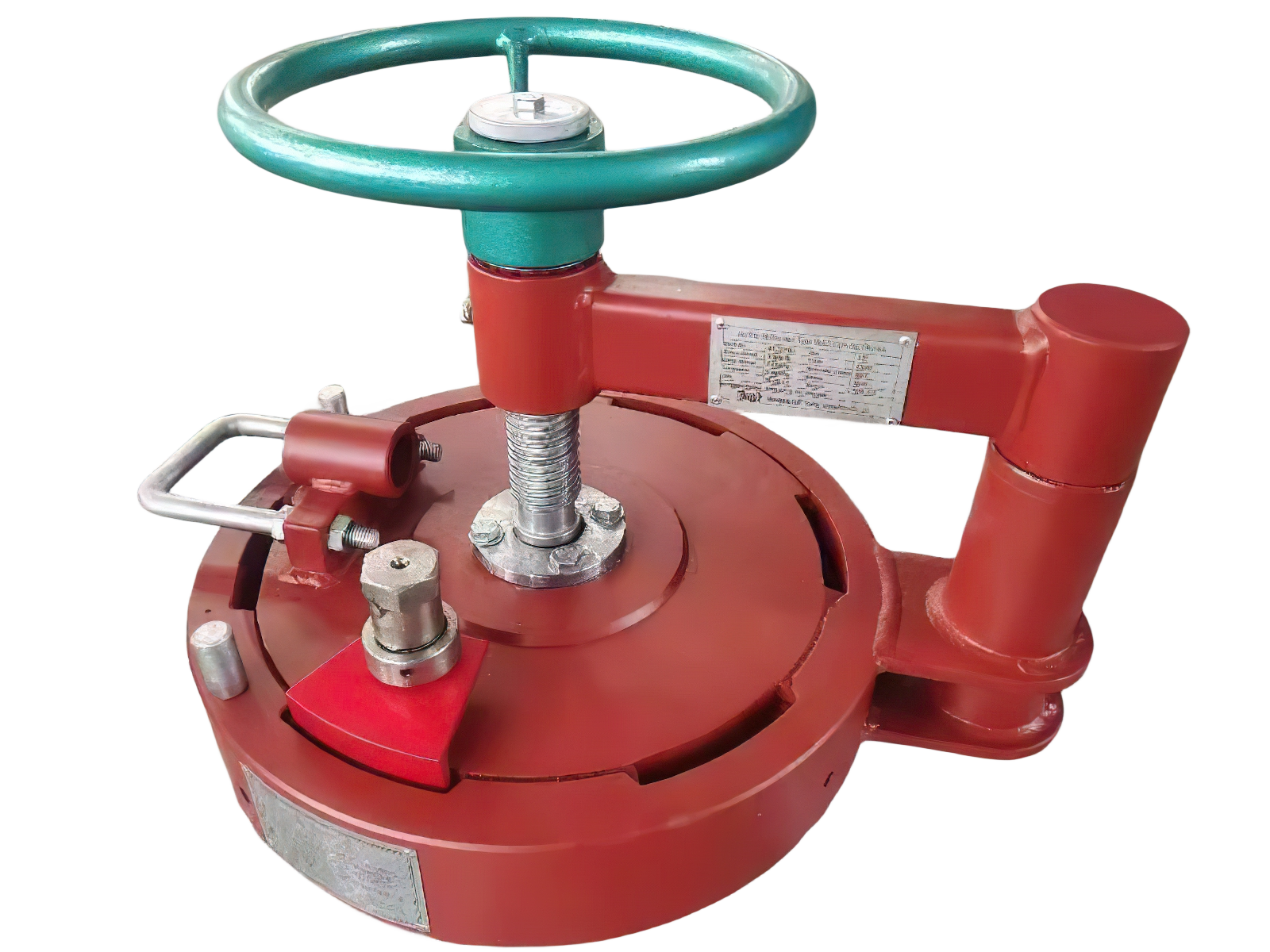

Rotating the Opening Bolt:

Once it is safe to proceed, the operator rotates the opening bolt. This action starts the unlocking process of the closure, paving the way for access to the interior of the pipeline.

Loosening the Clamps:

After unlocking the closure with the opening bolt, then the next step is to loosen the clamps. This adjustment allows the end closure to move freely, granting the necessary access for pigging operations.

Tightening the Opening Bolt and Closing the Safety Interlock Device:

Once compeleting the maintenance or inspection tasks, tighten the opening bolt to resecure the closure. Then, re-engage the safety interlock device to ensure the closure is safely locked. Now, the pipeline is ready to be pressurized again, concluding the operation.

Different Types

| Lock Ring Type | Band Type | Plug Buckle Type | |

| Installation | Vertical/Horizontal | Vertical/Horizontal | Vertical |

| Size | DN 200 to DN 1200 | DN 150 to DN 1000 | DN 150 to DN 1000 |

| Pressure | ASME #150 to #1500 | ASME #150 & #300 | ASME #150 to #600 |

| Materials | SA 350 LF2 | SA 350 LF2 | SA 516 70N/SA 105N |

| Sealing | Viton™ | Viton™ | Viton™ |