Description

Role of Pig Detectors in Pipeline Integrity Management

Pig detectors are essential for ensuring the integrity of pipeline systems. These devices monitor the progress of cleaning and inspection pigs as they travel through the pipeline, providing real-time updates on their location. This continuous monitoring allows for the immediate detection of issues such as blockages or wear, facilitating prompt intervention. The data gathered by pig detectors also empowers operators to make well-informed decisions regarding maintenance schedules and strategies. The integration of pig detectors into pipeline management increases safety, enhances operational efficiency, and promotes proactive maintenance approaches.

Importance of Pipeline Inspection and Maintenance

Regular inspection and maintenance are fundamental to the safety and efficiency of oil and gas pipeline operations. These practices are vital for preventing leaks and ruptures, which can cause significant environmental harm and disrupt operations, leading to substantial financial losses. Routine checks allow for the early detection of potential problems, thereby prolonging the pipeline’s operational life. Additionally, thorough maintenance ensures that pipelines maintain optimal flow rates, critical for achieving production goals and enhancing profitability. Consequently, consistent pipeline upkeep helps prevent unexpected downtime and ensures reliable product delivery.

Understanding Pig Detectors

Pig detectors play a crucial role in pipeline maintenance and inspection. These devices actively identify the presence and track the location of pigs as they navigate through pipelines. Operators use pigs as specialized tools for tasks such as cleaning, inspecting, or separating different materials within the pipeline. By ensuring that pigs effectively cover every part of the pipeline, pig detectors contribute to the increased efficiency and safety of pipeline operations.

Types of Pig Detectors

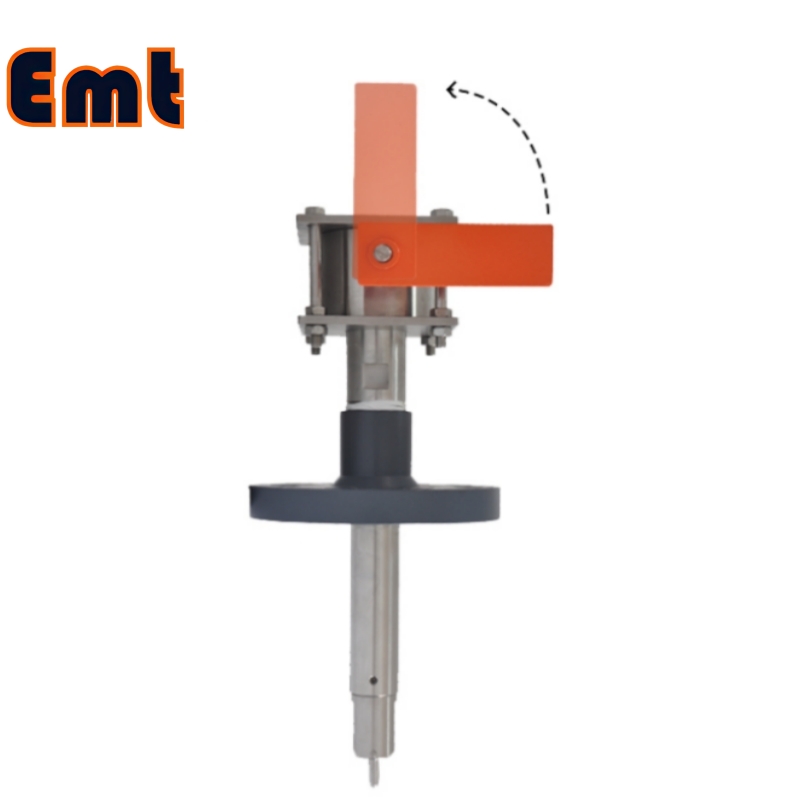

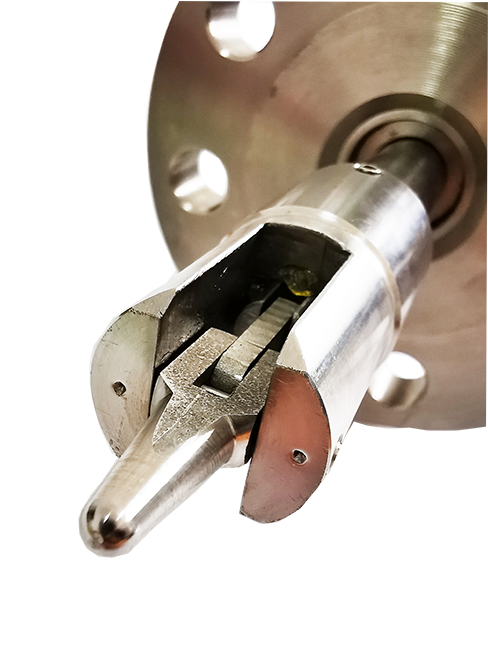

Intrusive Detectors

Intrusive detectors make physical contact with the pipeline. Operators install these devices directly into the pipeline wall, where they provide highly accurate data by detecting the exact moment a pig passes. This direct monitoring method yields precise data but involves modifying the pipeline for installation, which can compromise pipeline integrity and result in downtime.

Non-intrusive Detectors

In contrast, non-intrusive detectors operate without requiring physical alterations to the pipeline. These devices detect pigs by sensing changes in pressure, acoustic signals, or magnetic fields. Non-intrusive detectors are preferred for their ease of installation and minimal impact on pipeline integrity. They are adaptable to various materials and sizes of pipelines and reduce the risk of leaks and contamination since the pipeline remains intact.

Transitioning Between Types

The choice between intrusive and non-intrusive pig detectors depends on specific operational requirements. Intrusive detectors are suitable when accurate data collection is critical and minor modifications to the pipeline are acceptable. On the other hand, non-intrusive detectors are better for situations where quick installation and minimal disruption are priorities.

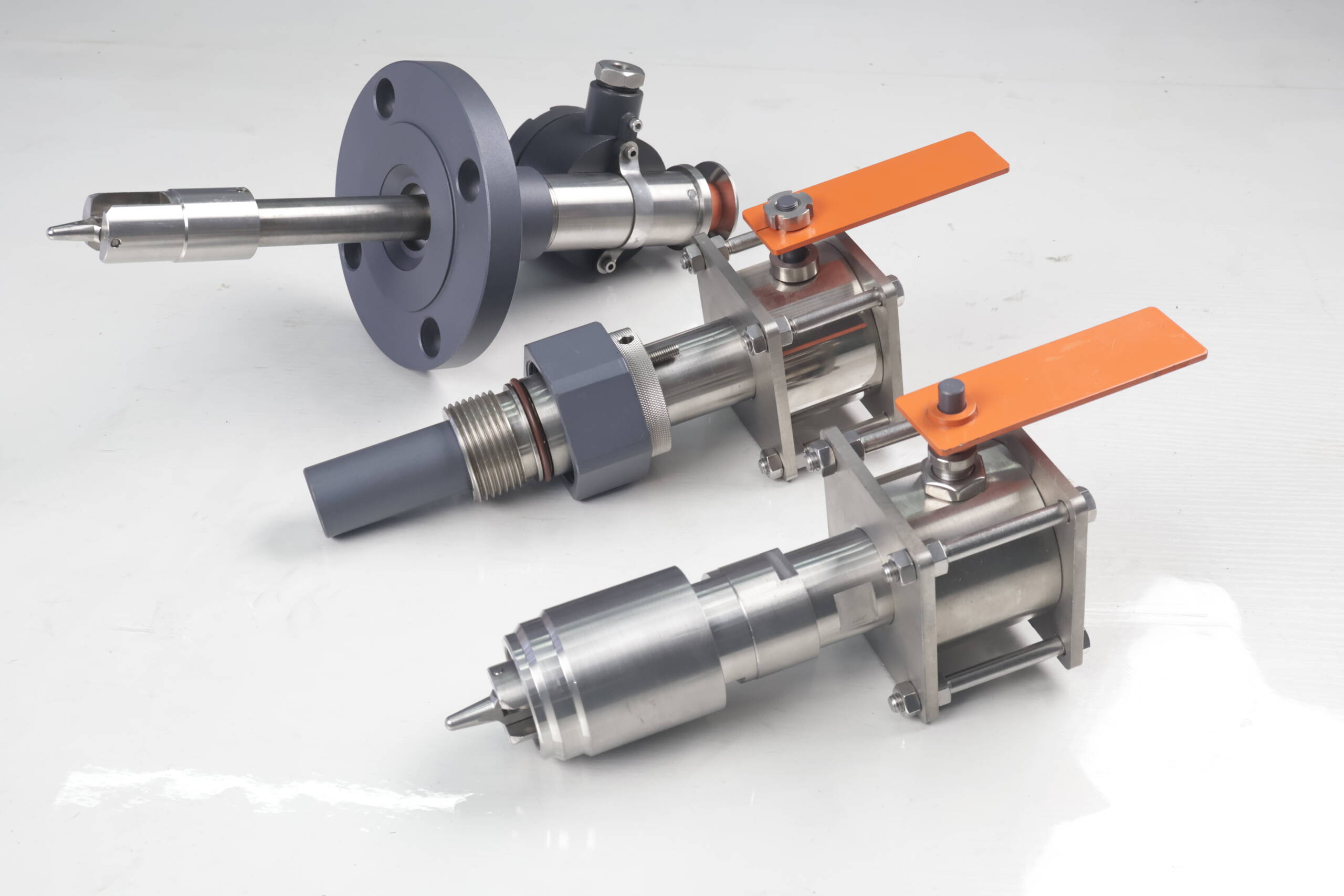

Different Types

Intrusive pig detectors offer precise data collection through their direct installation into the pipeline. This section delves into the two primary types: flange connection pig detectors and weld connection pig detectors.

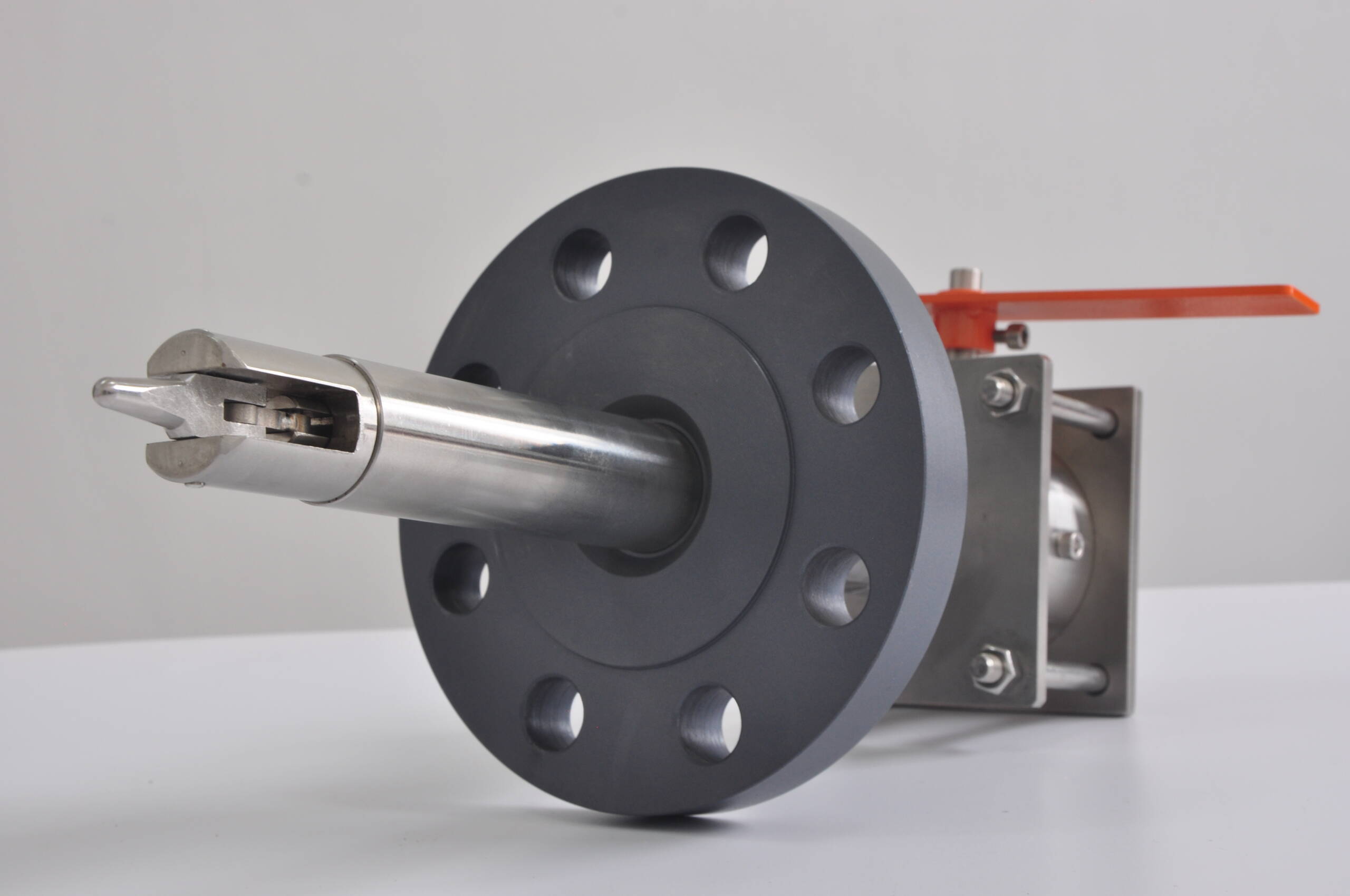

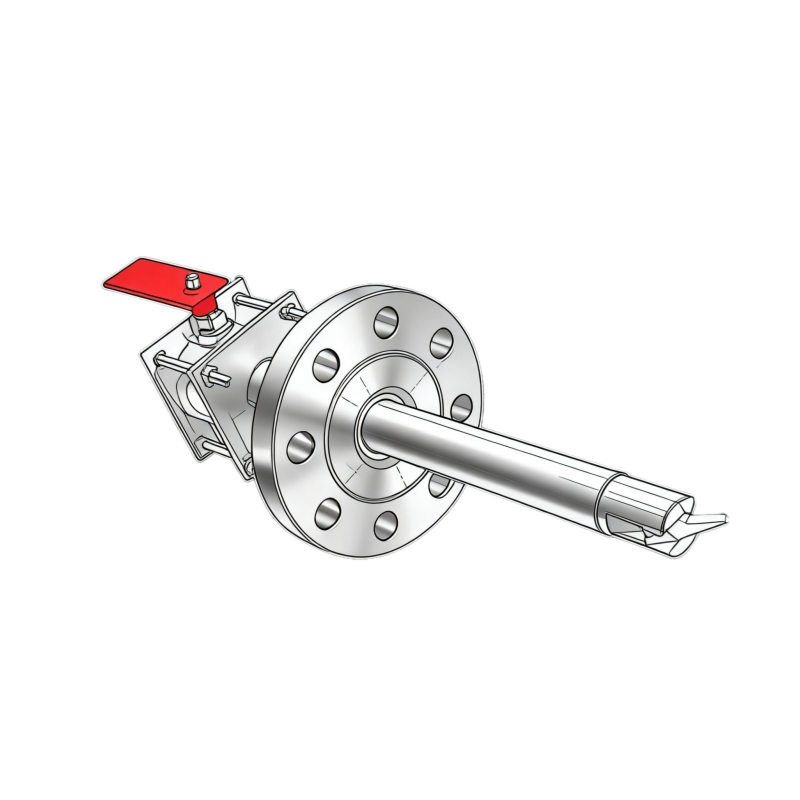

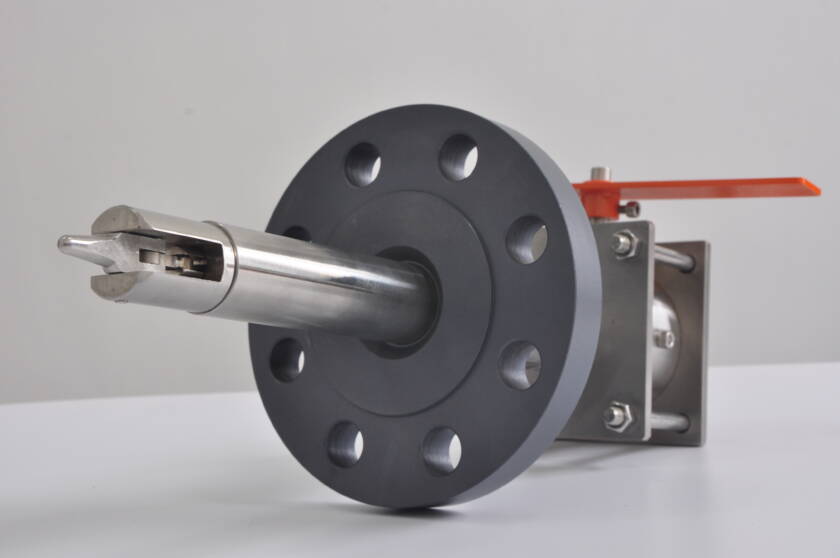

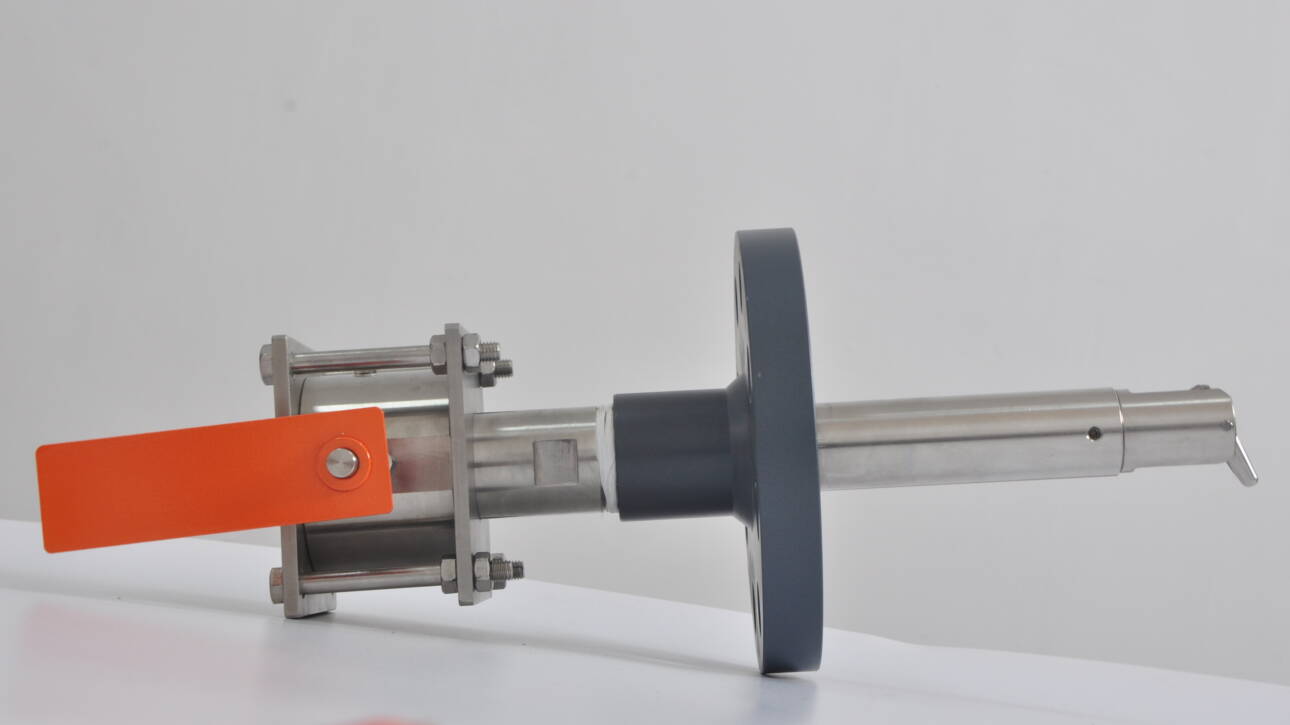

Flange Connection

Flange connection pig detectors are installed using a flanged joint, which allows for easy integration into the pipeline. This type is favored for its straightforward installation and maintenance, involving bolting the detector to a flange already present on the pipeline. This approach simplifies setup and allows for quick access for maintenance or modifications without significant alterations to the pipeline. Flange connection pig detectors are adaptable, suited for both temporary and permanent setups, and perform reliably under a variety of conditions, making them a preferred choice across various industries.

Additionally, the design ensures a tight seal, minimizing leak risks and maintaining the integrity of the contents being transported. Industries that require regular pigging operations often choose this type due to the ease of disassembly it offers.

Weld Connection

Weld connection pig detectors, on the other hand, are known for their long-term durability and are permanently installed by welding them directly to the pipeline. This method creates a strong, leak-proof connection, making these detectors suitable for high-pressure scenarios and severe operational conditions.

Weld connection detectors are particularly effective in harsh environments where pipelines may be exposed to extreme temperatures or corrosive materials. The permanence of the weld ensures that the detector remains stable and securely attached over extended periods. Despite their lack of flexibility compared to flange connection models, the durable nature of weld connection detectors makes them ideal for long-term applications, though their installation and maintenance require specialized welding skills.

Advantages of Using Pig Detectors in the Oil Industry

Early Detection of Pipeline Issues

Pig detectors are invaluable in enhancing pipeline management through the early detection of anomalies and potential failures. These devices are capable of identifying obstructions, corrosion, and cracks early on, providing operators with the opportunity to address these problems before they develop into severe issues. This early detection enables timely corrective actions, which helps prevent substantial damage, ensures smoother pipeline operations, and protects the quality of the materials being transported. Such proactive management not only maintains consistent flow but also preserves the integrity of the transported products.

Minimizing Downtime and Reducing Maintenance Costs

Pig detectors contribute significantly to reducing downtime by identifying problems at their inception. This allows operations to continue with minimal interruptions, thus sustaining productivity and protecting revenue streams. Early problem resolution means that repairs can be conducted when issues are still minor, which reduces the extent and cost of maintenance. Regular deployment of pig detectors during routine inspections can decrease both the frequency and severity of maintenance tasks. Consequently, this reduction in unplanned shutdowns and maintenance costs drastically lowers overall operating expenses and prolongs the pipeline’s lifespan, enhancing the return on infrastructure investment.

Ensuring Compliance with Safety and Regulatory Standards

Pig detectors are essential for ensuring adherence to safety and regulatory standards in many industries. These standards are often stringent and mandate high levels of pipeline integrity and safety. By utilizing pig detectors, operators can maintain these high safety standards, ensuring that pipelines are safe for workers, the public, and the environment. Compliance not only helps avoid legal repercussions but also enhances the company’s reputation as a responsible and dependable operator.